Sheet Metal Processing is a comprehensive cold working process for metal sheets (usually below 6mm), including shearing, punching, bending, welding, riveting, mold forming, and surface treatment. Its prominent feature is that the thickness of the same part is consistent.

Sheet metal processing method: Non mold processing: The process of sheet metal processing through equipment such as numerical punching, laser cutting, shearing machines, bending machines, riveting machines, etc. It is generally used for sample production or small batch production, with high costs. Short processing cycle and rapid response. Mold processing: Using fixed molds to process sheet metal, there are generally cutting molds and forming molds, mainly used for mass production with lower costs. The initial mold cost is high, and the quality of the parts is guaranteed. The early processing cycle is long and the mold cost is high. Sheet metal processing process: cutting: numerical punching, laser cutting, shearing machine

Forming - bending, stretching, punching: bending machines, punching machines, etc

Other processing: riveting, tapping, etc

Welding: the connection method of sheet metal

Surface treatment: powder spraying, electroplating, wire drawing, screen printing, etc

Sheet metal processing technology - The main cutting methods for sheet metal include numerical punching, laser cutting, shearing machines, and mold cutting. CNC is currently a commonly used method, and laser cutting is mostly used in the sampling stage (or can also process stainless steel sheet metal parts), with high processing costs. Mold cutting is mostly used for large-scale processing.

Below, we will mainly introduce the cutting of sheet metal using numerical punching

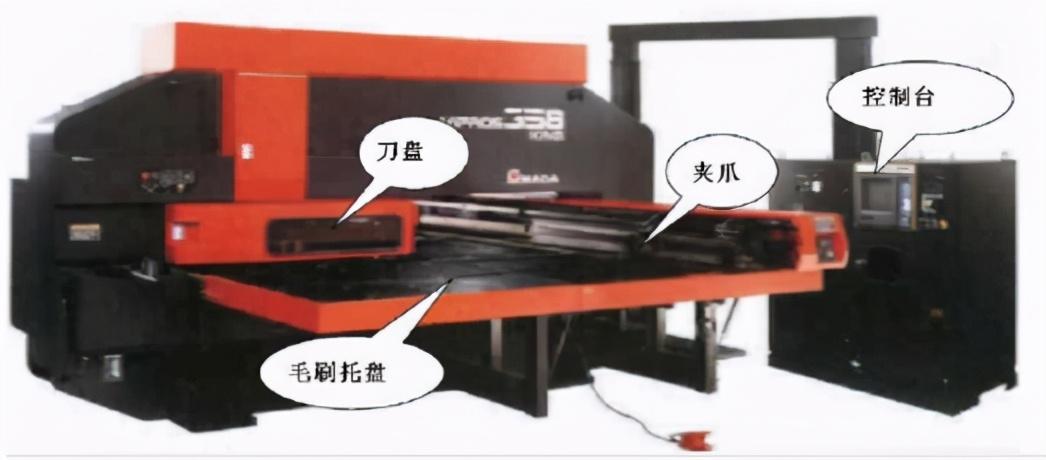

Numerical punching, also known as turret CNC punching machine, can be used for cutting, punching, stretching holes, rolling ribs, punching blinds, etc. Its machining accuracy can reach+/-0.1mm.

The thickness of the CNC machinable sheet metal is:

Cold rolled and hot-rolled plates 4.0mm

Aluminum plate 5.0mm

Stainless steel plate 2.0mm

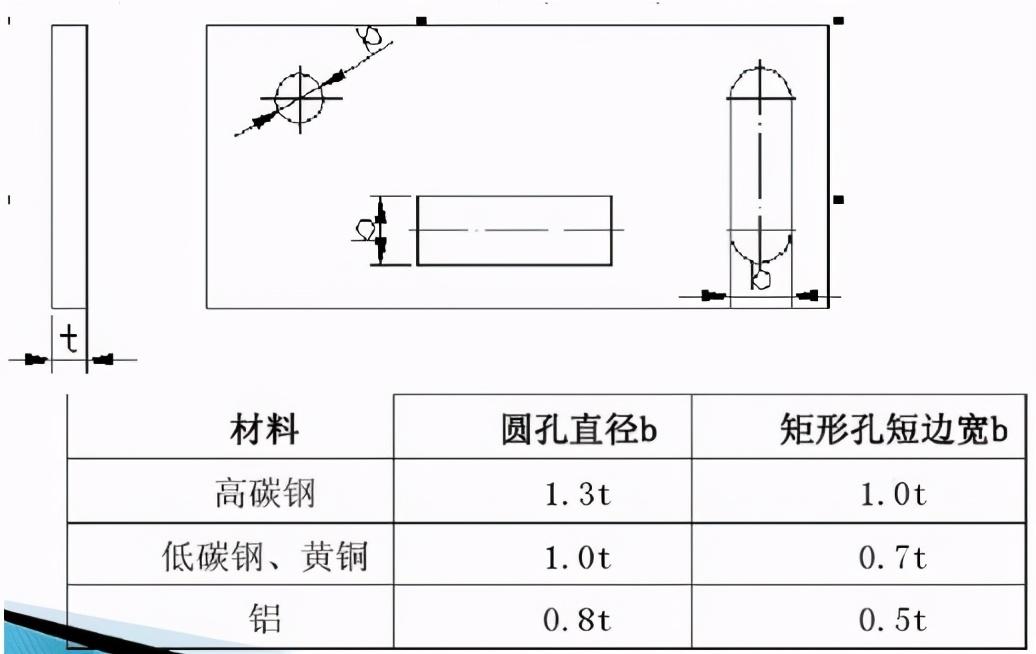

There is a minimum size requirement for punching. The minimum size of punching is related to the shape of the hole, the mechanical properties of the material, and the thickness of the material. (As shown in the figure below)

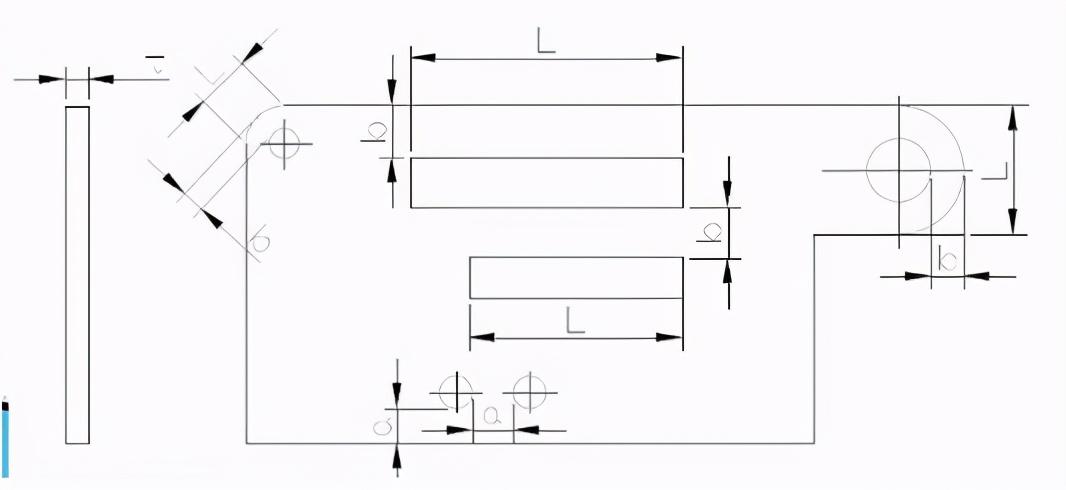

2. The spacing and edge distance of the punching holes. When the minimum distance between the punching edge of the part and the outer edge of the part is not parallel to the outer edge of the part, the minimum distance should not be less than the material thickness t; When parallel, it should not be less than 1.5t. (As shown in the figure below)

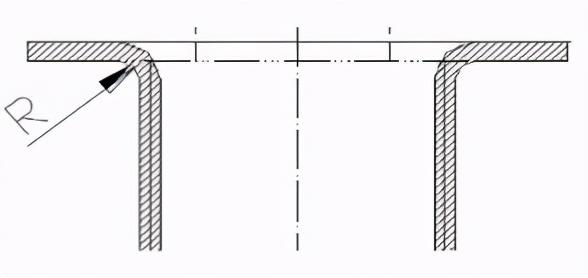

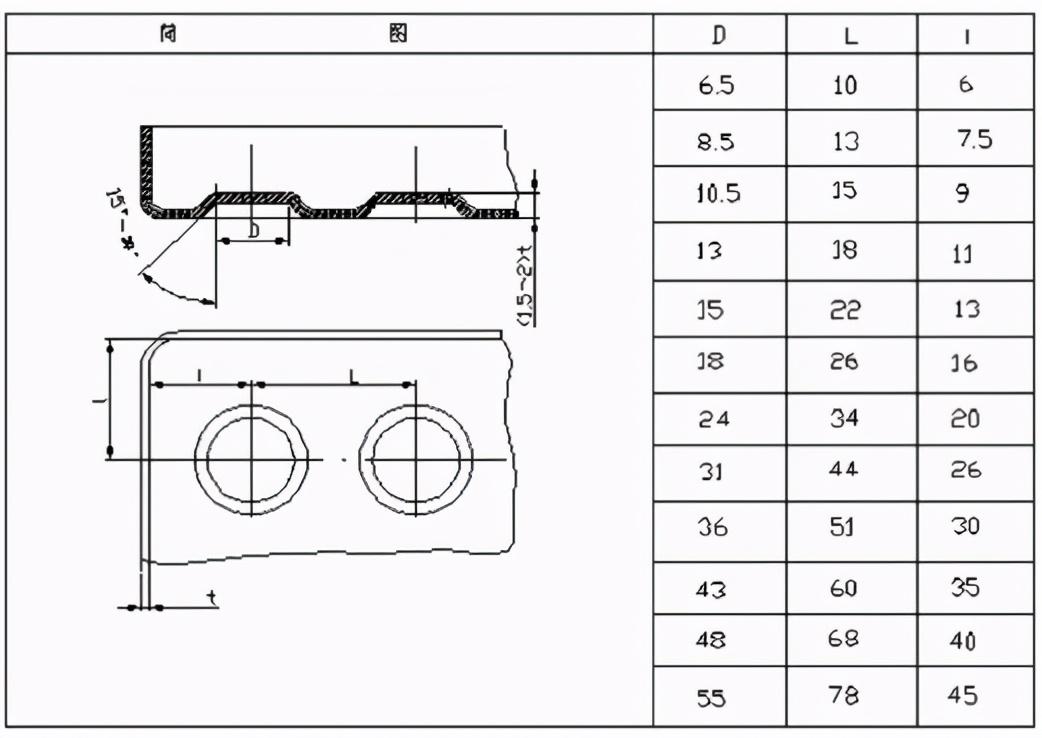

3. When stretching holes, the minimum distance between the stretching hole and the edge is 3T, the minimum distance between two stretching holes is 6T, and the minimum safe distance between the stretching hole and the bending edge (inside) is 3T+R (T is the sheet metal thickness, R is the bending fillet)

4. When punching holes in stretched and bent parts and deep drawn parts, a certain distance should be maintained between the hole wall and the straight wall. (As shown in the figure below)

Sheet metal processing technology - Forming sheet metal mainly involves bending and stretching the sheet metal.

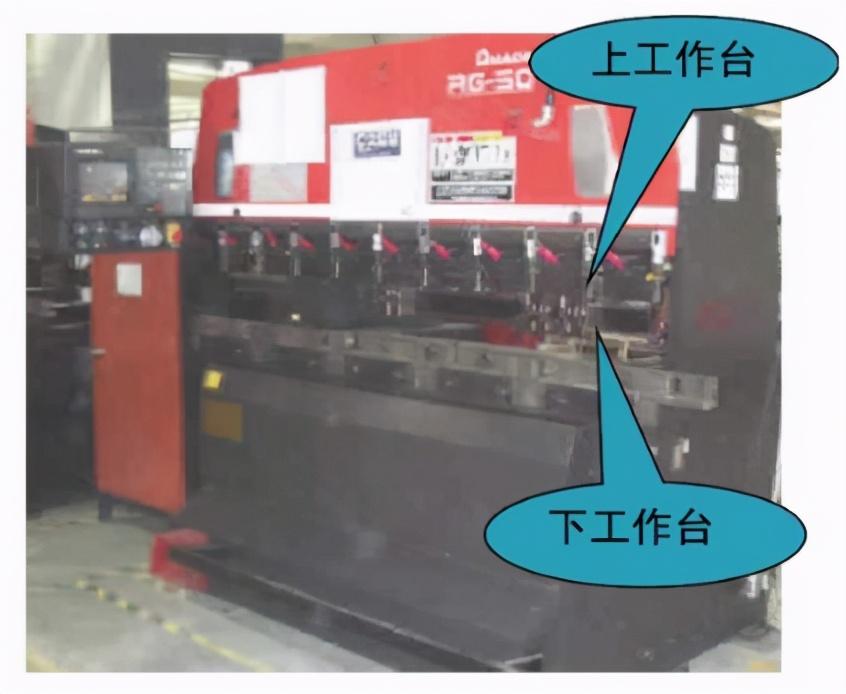

1. Sheet metal bending 1.1 Sheet metal bending mainly uses bending machines.

The machining accuracy of the folding machine;

One fold:+/-0.1mm

Half Fold:+/-0.2mm

Over 20% discount:+/-0.3mm

The basic principle of bending processing sequence is to bend from inside out and from small to large. Special shapes should be bent first, and the previous process should not affect or interfere with the subsequent processes after forming.

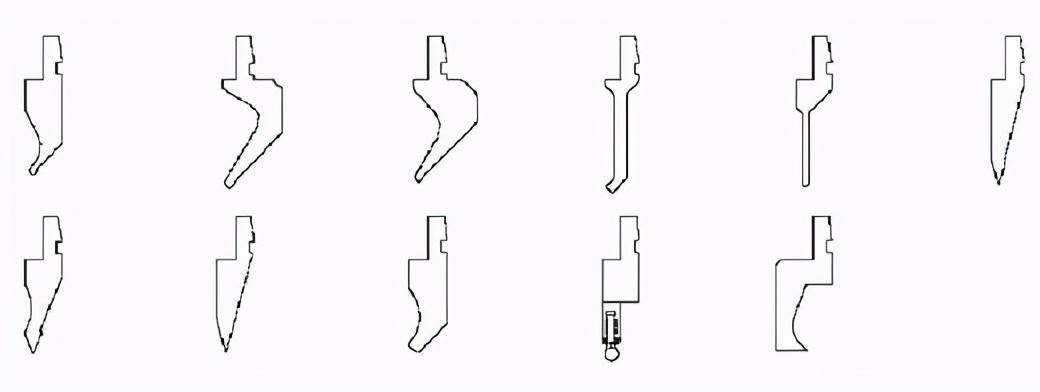

1.3 Common bending knife shapes:

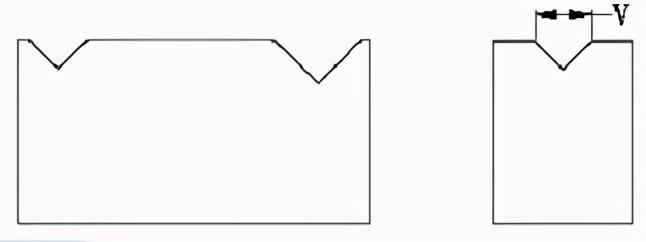

Common V-groove shapes:

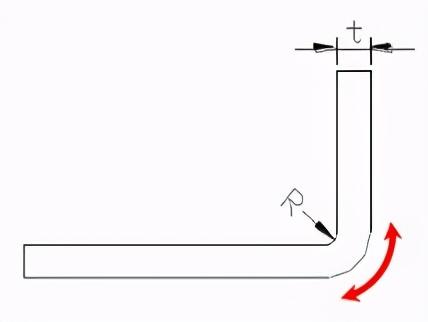

1.4 Minimum bending radius of bent parts:

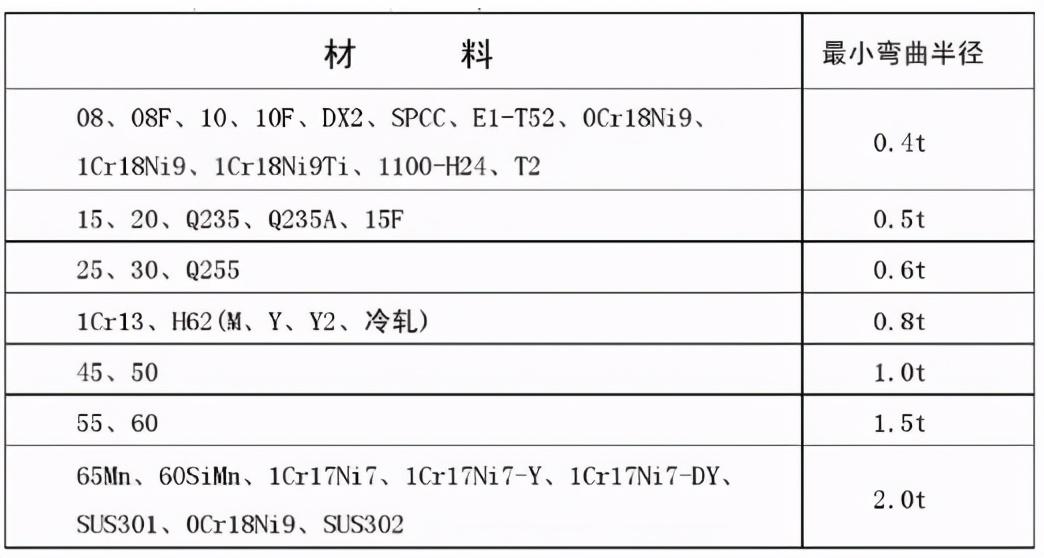

When the material is bent, the outer layer is stretched and the inner layer is compressed in the rounded area. When the material thickness is constant, the smaller the internal r, the more severe the tension and compression of the material; When the tensile stress of the outer rounded corner exceeds the ultimate strength of the material, cracks and fractures will occur. Therefore, the structural design of bent parts should avoid too small bending rounded corner radii. The minimum bending radius of commonly used materials in the company is shown in the table below.

Minimum bending radius table for bent parts:

The bending radius refers to the inner radius of the bent part, and t is the wall thickness of the material.

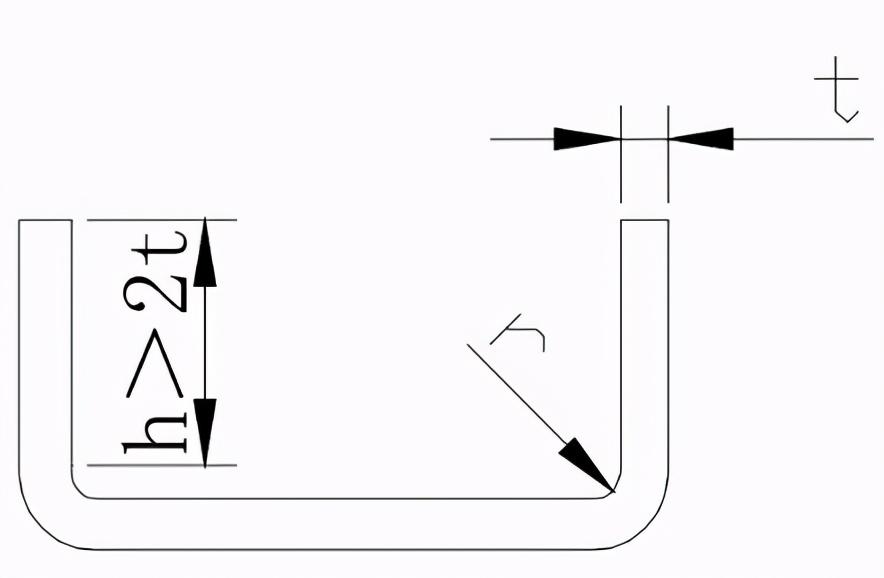

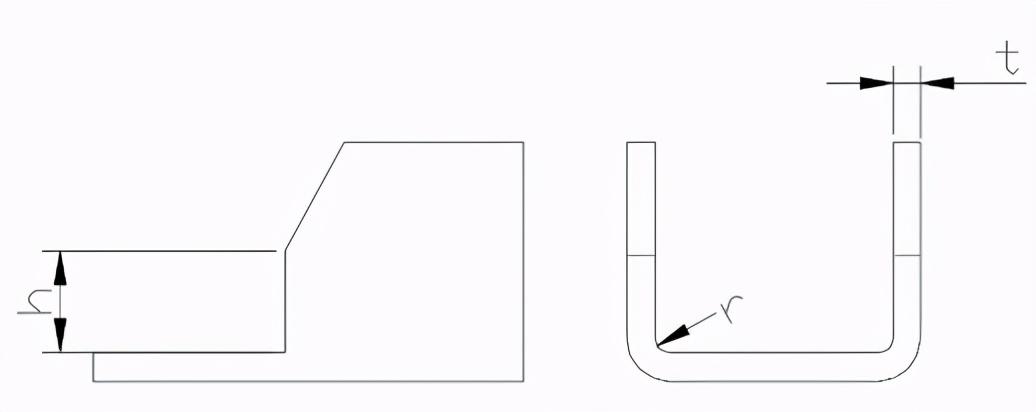

The straight edge height of the bent part is 1.5:

In general, the minimum straight edge height should not be too small, and the minimum height requirement is: h>2t

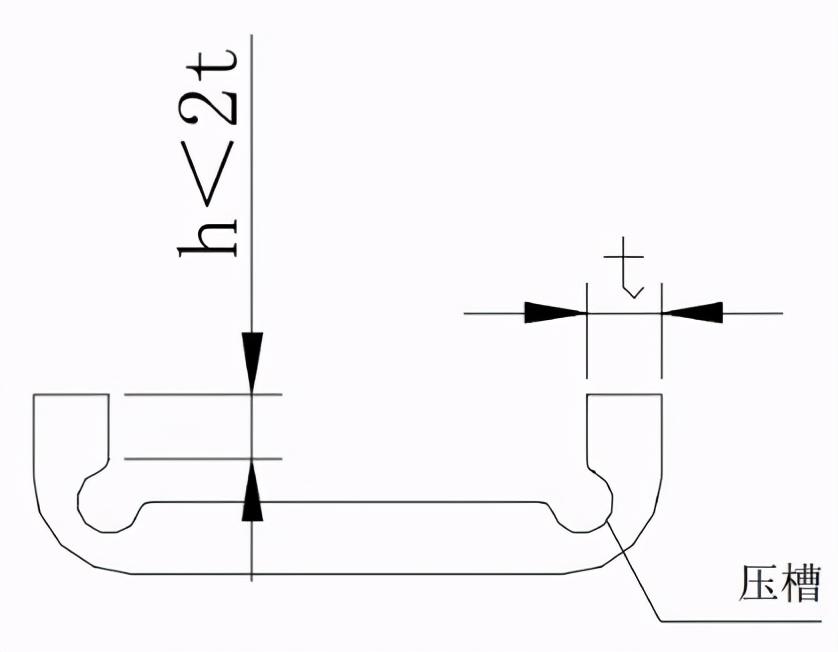

If the straight edge height h2t of the bent part is required, first increase the bending edge height, and then process it to the required size after bending; Or, after processing shallow grooves in the bending deformation zone, perform bending.

1.6 Minimum bending straight edge height with oblique angle on the curved edge:

When a curved part with a slanted edge is bent, the minimum height of the side is: h=(2-4) t> 3mm

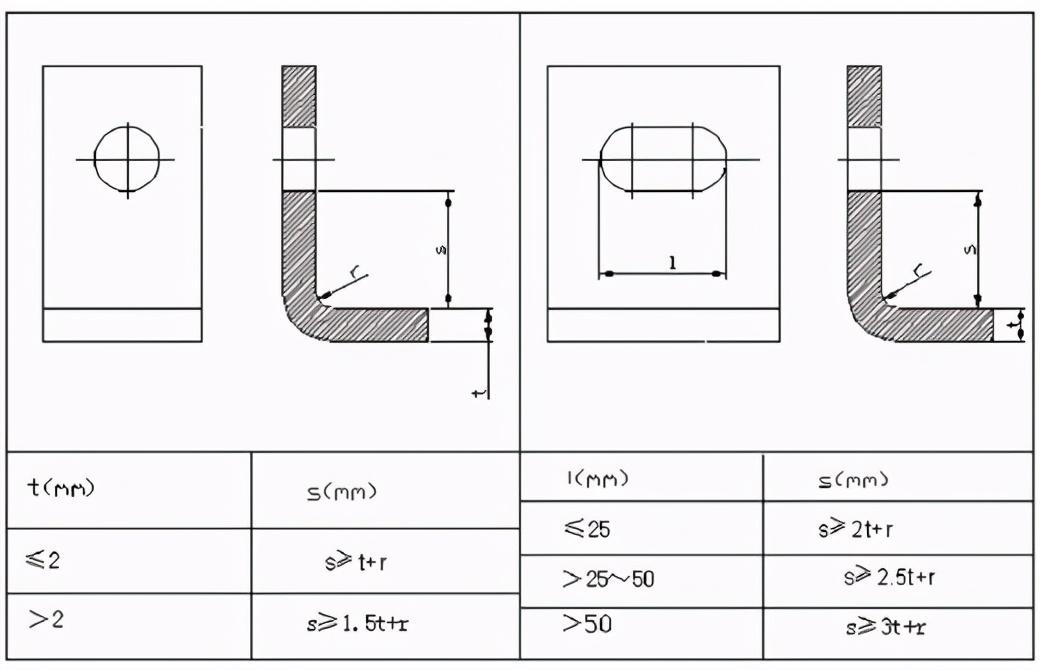

1.7 Edge distance of holes on bent parts:

Hole edge distance: Punch the hole first and then bend it. The position of the hole should be outside the bending deformation zone to avoid deformation of the hole during bending. The distance from the hole wall to the curved edge is shown in the table below.

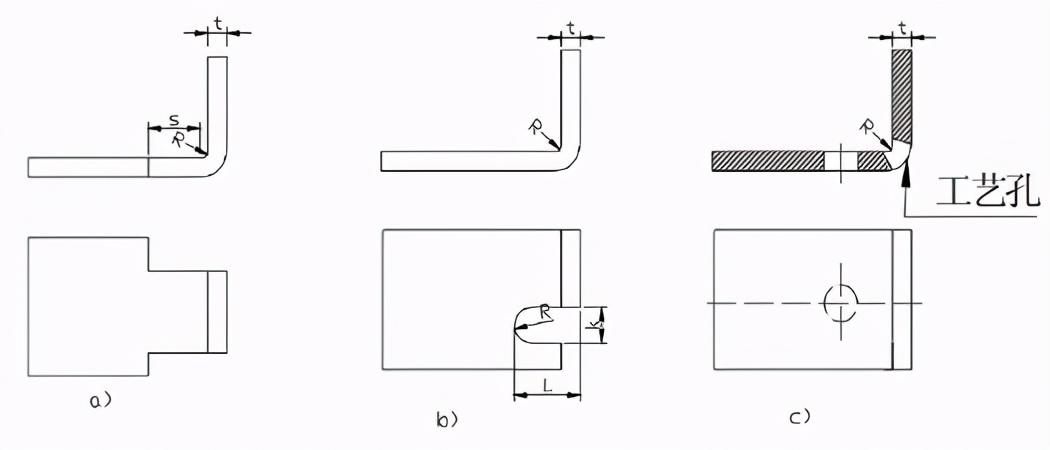

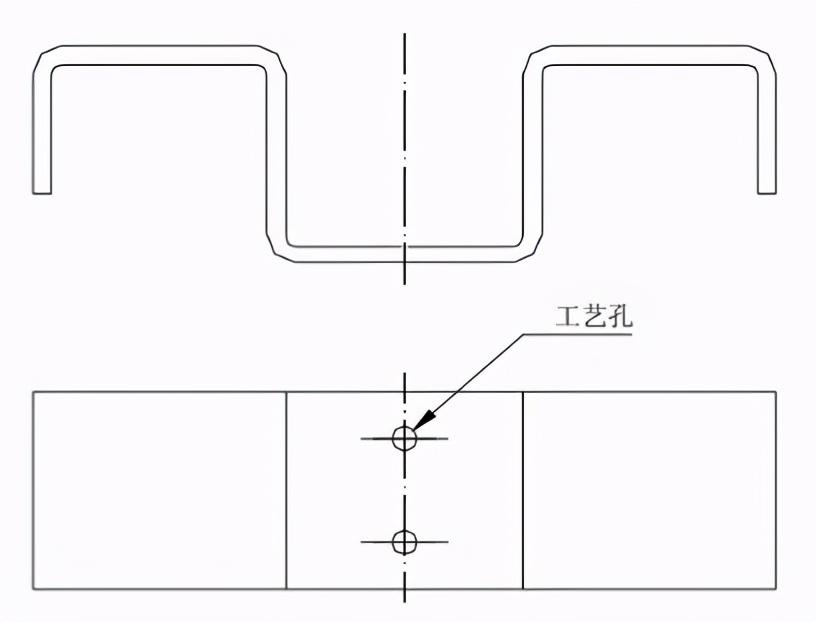

1.8 Process incision for local bending:

The bending line of the bent part should avoid the position of sudden size changes. When bending a certain segment of the edge locally, in order to prevent stress concentration and cracking at sharp corners, the bending curve can be moved a certain distance to leave the sudden change in size (Figure a), or a process groove (Figure b) can be opened, or a process hole can be punched (Figure c). Pay attention to the size requirements in the diagram: SR; Slot width kt; Slot depth Lt+R+k/2.

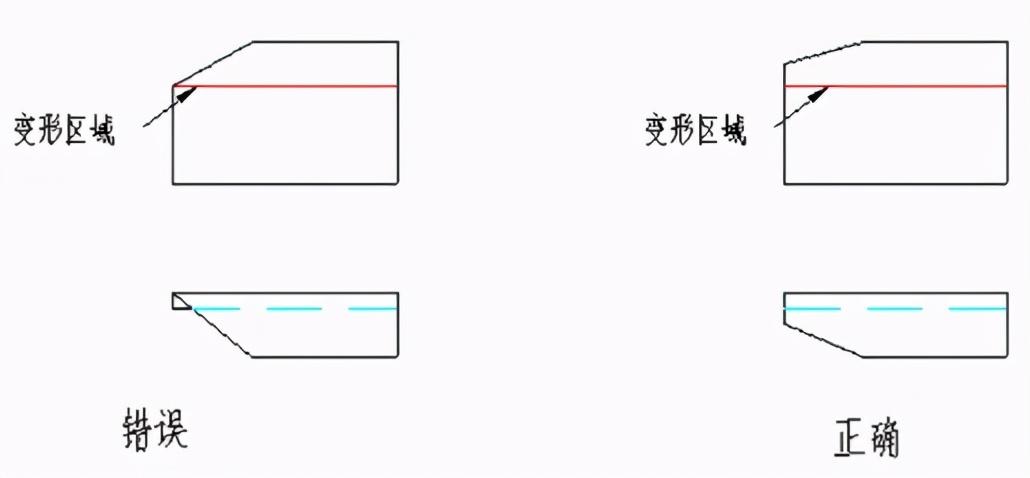

1.9 Bending edges with beveled edges should avoid deformation zones:

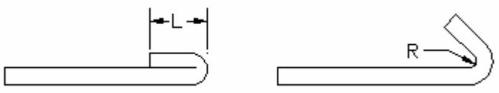

1.10 Design requirements for sheet metal pleats (dead edges):

The dead edge length of sheet metal pleats is related to the thickness of the material. As shown in the following figure, the minimum length of a dead edge is generally L3.5t+R.

Among them, t is the material wall thickness, and R is the minimum internal bending radius of the previous process (as shown on the right in the figure below) before the edge is killed.

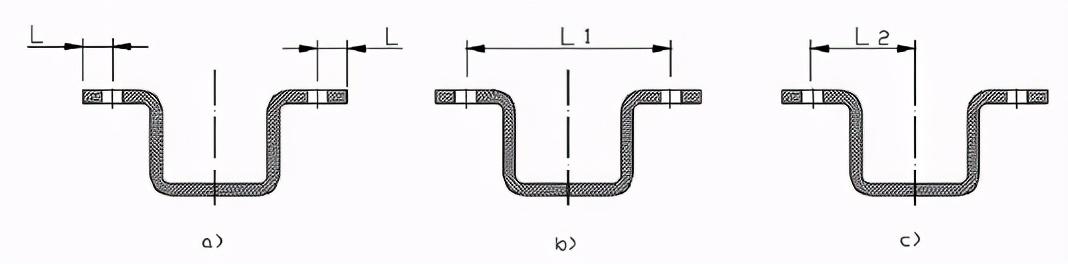

1.11 Process positioning holes added:

To ensure the accurate positioning of the blank in the mold and prevent the deviation of the blank during bending, process positioning holes should be added in advance during design, as shown in the following figure. Especially for parts that have been bent multiple times, the process holes must be used as the positioning reference to reduce cumulative errors and ensure product quality.

When labeling the dimensions of bent parts, consideration should be given to processability:

As shown in the above figure, a) punching first and then bending, the L dimension accuracy is easy to ensure, and the processing is convenient. b) If the precision requirement for dimension L is high, it is necessary to bend first and then process the hole, which is troublesome to process.

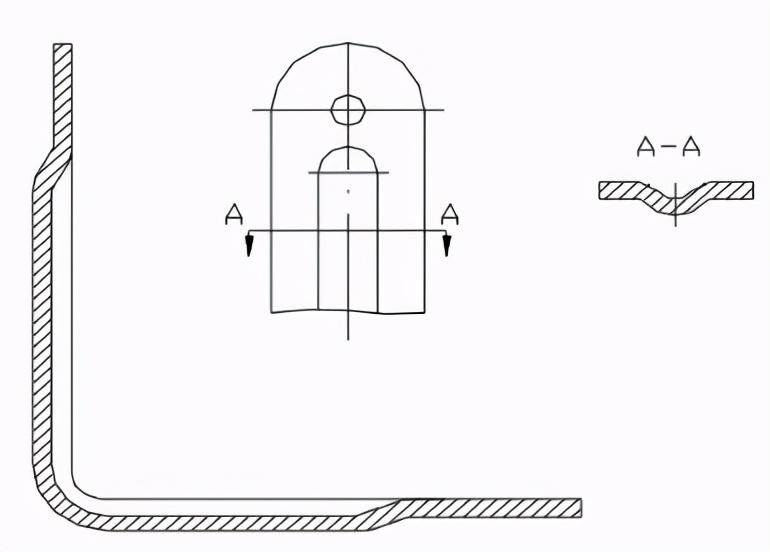

There are many factors that affect the springback of bent parts, including the mechanical properties of the material, wall thickness, bending radius, and positive pressure during bending. The larger the ratio of the inner radius of the bent part to the plate thickness, the greater the rebound. The method of suppressing rebound from a design perspective, such as the rebound of bent parts, is currently mainly avoided by manufacturers during mold design by taking certain measures. At the same time, improving certain structures in design can reduce the springback angle, as shown in the following figure: pressing reinforcement ribs in the bending area can not only increase the stiffness of the workpiece, but also help suppress springback.

2. Sheet metal stretching The stretching of sheet metal is mainly completed by CNC or conventional punching, requiring various stretching punches or molds.

The shape of the stretched part should be as simple and symmetrical as possible, and should be formed in one stretch as much as possible.

Parts that require multiple stretches should allow for possible surface marks during the stretching process.

On the premise of ensuring assembly requirements, it should be allowed to stretch the sidewalls with a certain inclination.

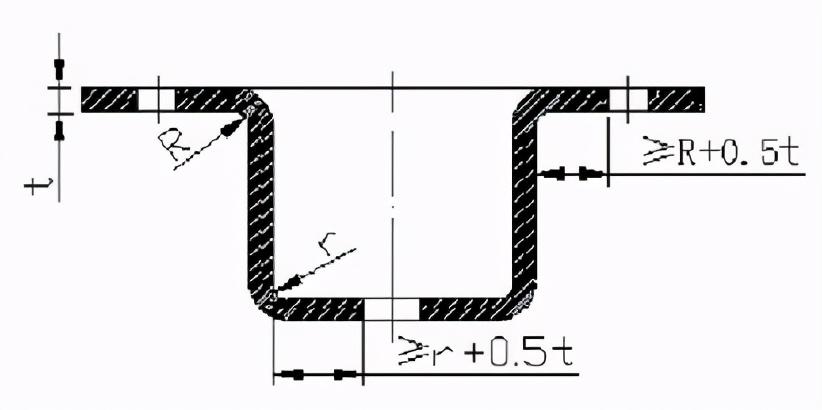

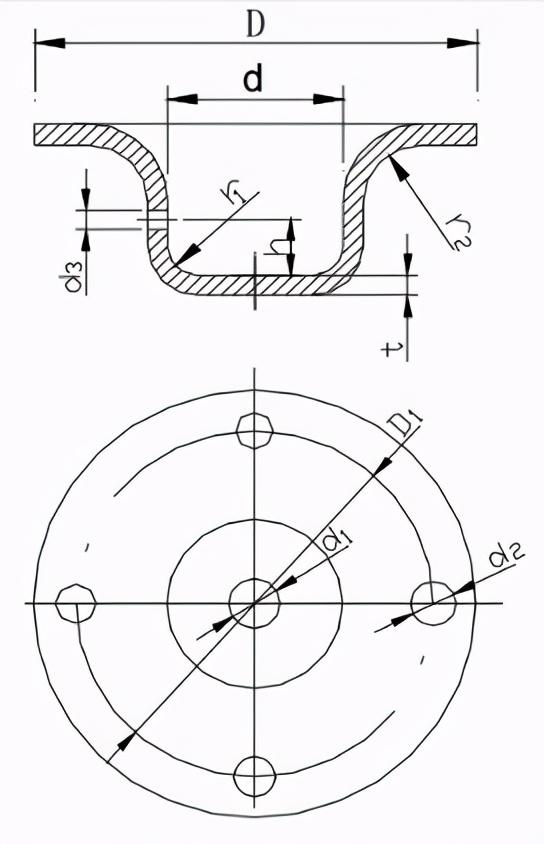

2.1 Requirements for the fillet radius between the bottom of the stretched part and the straight wall:

As shown in the figure below, the fillet radius between the bottom of the stretched part and the straight wall should be greater than the plate thickness, i.e. r1t. In order to make the stretching process smoother, r1=(3-5) t is generally taken, and the maximum fillet radius should be less than or equal to 8 times the plate thickness, which is r18t.

2.2 Rounding radius between the flange and wall of the stretched part

The radius of the fillet between the flange and the wall of the stretched part should be greater than twice the thickness of the plate, i.e. r22t. In order to make the stretching process smoother, r2=(5-10) t is generally taken, and the maximum flange radius should be less than or equal to 8 times the thickness of the plate, i.e. r28t. (Refer to the above figure)

2.3 Inner cavity diameter of circular stretched parts

The inner diameter of the circular stretching piece should be taken as D d+10t, so that the pressure plate is pressed tightly without wrinkling during stretching. (Refer to the above figure)

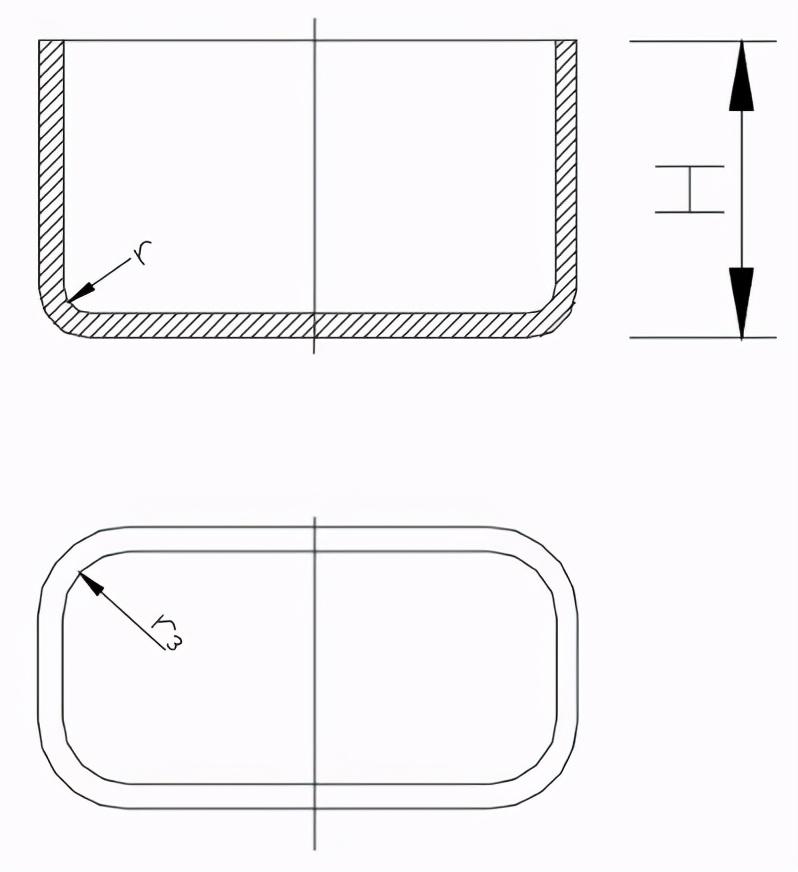

2.4 Rounding radius between adjacent walls of rectangular stretched parts

The radius of the fillet between adjacent walls of a rectangular stretched piece should be taken as r3 3t. In order to reduce the number of stretches, r3 H/5 should be taken as much as possible, so that it can be pulled out in one go.

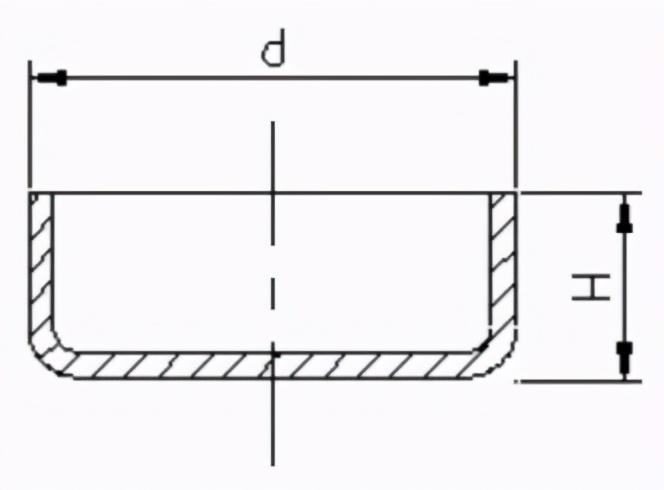

Requirements for the dimensional relationship between the height and diameter of a 2.5 round flange free stretching part during one-time forming

When forming a circular flange free stretching part in one go, the ratio of height H to diameter d should be less than or equal to 0.4, i.e. H/d 0.4, as shown in the following figure.

2.6 Thickness variation of stretched material:

The thickness of the stretched material changes due to the varying levels of stress applied to each part. Generally speaking, the original thickness is maintained at the center of the bottom, the material at the rounded corners of the bottom becomes thinner, the material near the flange at the top becomes thicker, and the material around the rounded corners of the rectangular stretched part becomes thicker.

2.7 Marking method for product dimensions of stretched parts

When designing stretch products, the dimensions on the product drawing should be clearly indicated to ensure both external and internal dimensions are guaranteed, and internal and external dimensions cannot be marked simultaneously.

2.8 Method for annotating dimensional tolerances of stretched parts

The inner radius of the concave convex arc of the stretched part and the height dimension tolerance of the cylindrical stretched part formed in one go are double-sided symmetrical deviations, with a deviation value of half of the absolute value of the precision tolerance of the national standard (GB) level 16, and are numbered.

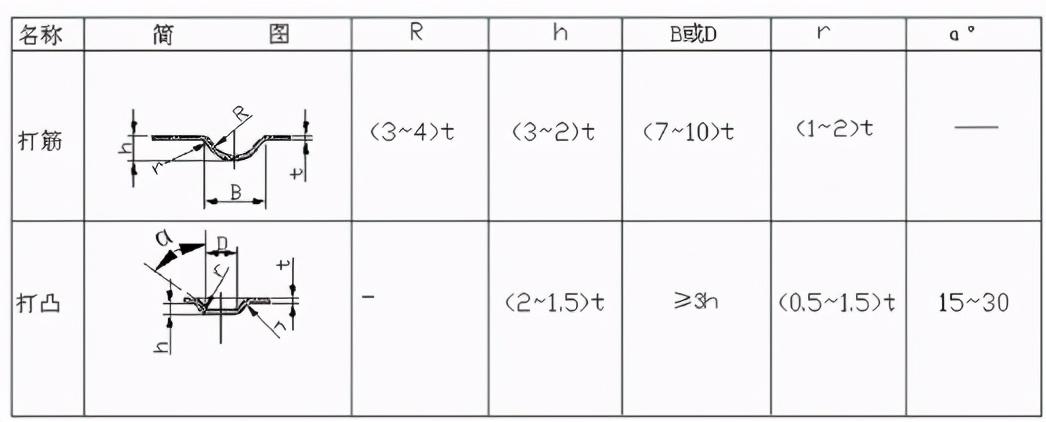

3. Other forming of sheet metal: Reinforcing ribs - Pressing ribs on flat metal parts helps to increase structural rigidity.

Louvers - Louvers are commonly used on various casings or casings to provide ventilation and heat dissipation.

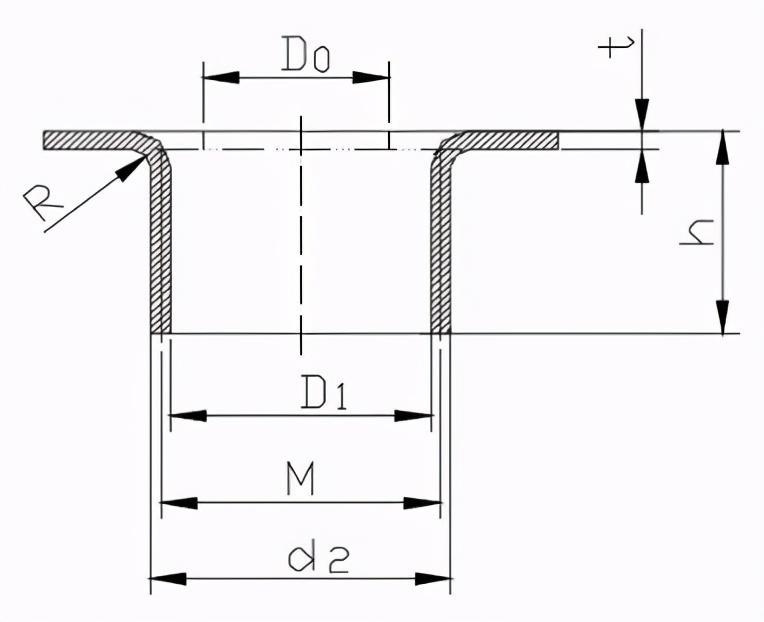

Hole flange (stretching hole) - used to machine threads or increase the rigidity of the hole opening.

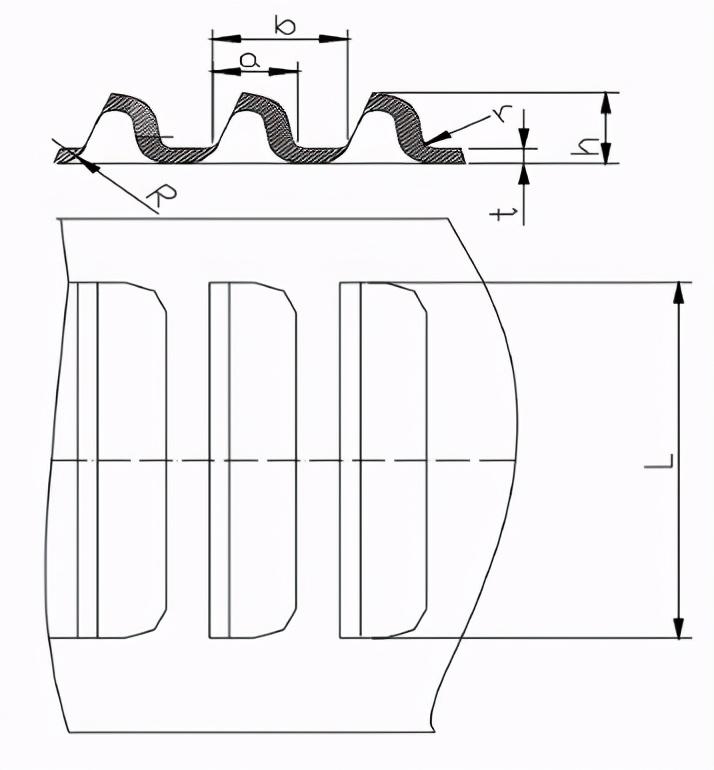

3.1 Reinforcement:

Reinforcement Structure and Size Selection

The maximum dimensions for convex spacing and convex edge distance are selected according to the table below.

3.2 Louvers

The method of forming blinds is to cut open the material using one edge of the convex mold, while the remaining parts of the convex mold simultaneously stretch and deform the material, forming a undulating shape with one side opening.

The typical structure of the louver is shown in the following figure

Louver size requirement: a4t; b6t;h5t;L24t;r0.5t。

3.3 Flanging of holes (stretching holes)

There are many forms of hole flanging, and the common one is to machine the inner hole flanging of threads.

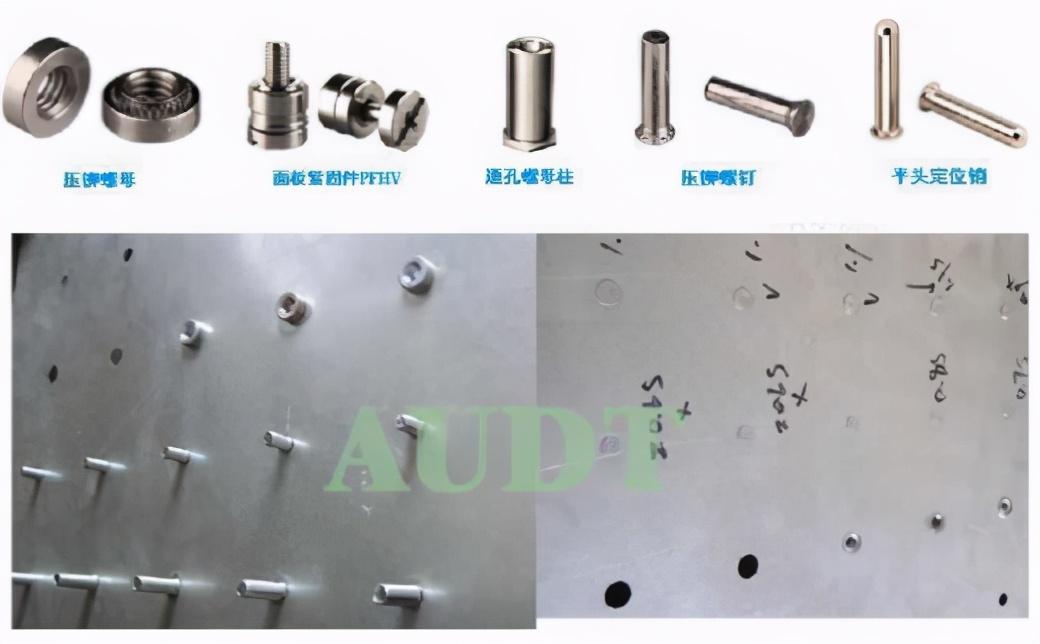

Sheet metal processing technology - riveting of other processed sheet metal accessories, such as rivet nuts, rivet bolts, rivet guide columns, etc.

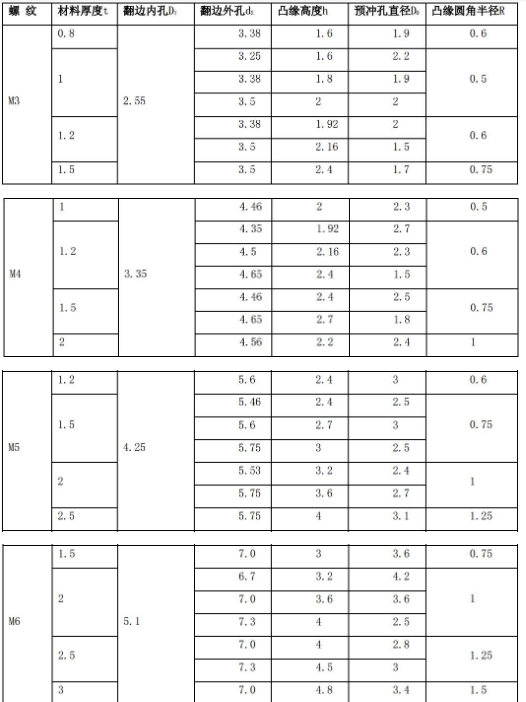

2. Tapping of threaded holes on sheet metal.

Sheet metal thickness t< At 1.5 o'clock, use flipped edge tapping. When the sheet metal thickness is t1.5, direct tapping can be used.

Sheet metal processing technology - When welding in the design of sheet metal welding structures, it should be implemented to "symmetrically arrange welds and welding points, and avoid intersection, aggregation, and overlap. Secondary welds and welding points can be interrupted, and main welds and welding points should be connected."

Welding commonly used in sheet metal includes arc welding, resistance welding, etc.

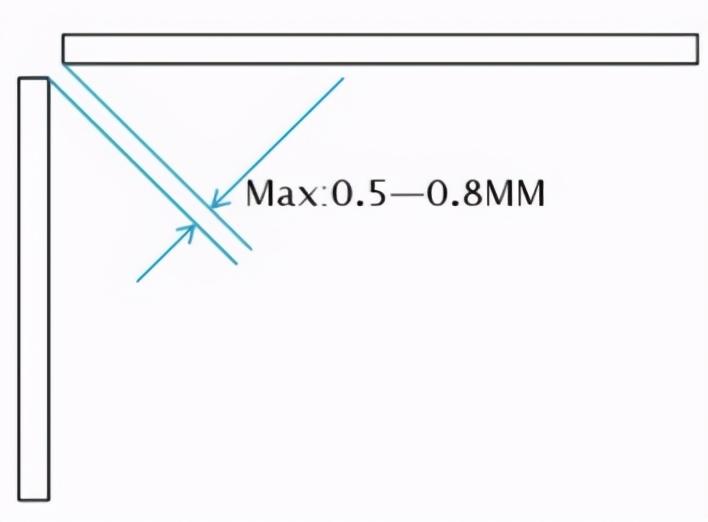

There should be sufficient welding space between arc welded sheet metal, and the maximum welding gap should be between 0.5 and 0.8mm. The weld seam should be uniform and flat.

2. The welding surface of resistance welding should be flat, without wrinkles, rebound, etc.

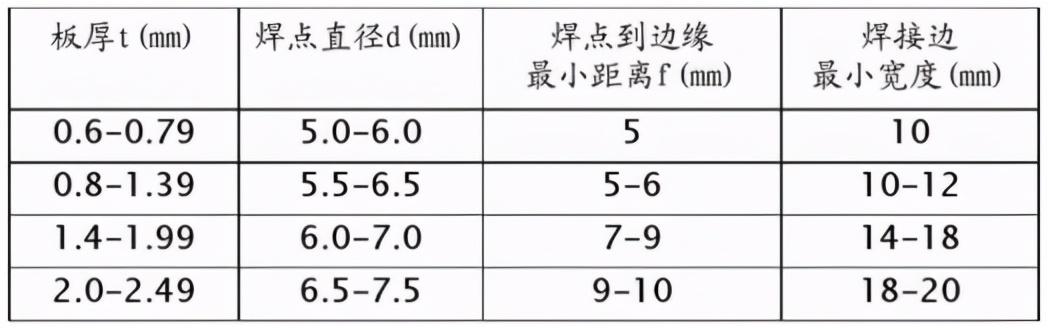

The dimensions of resistance welding are shown in the table below:

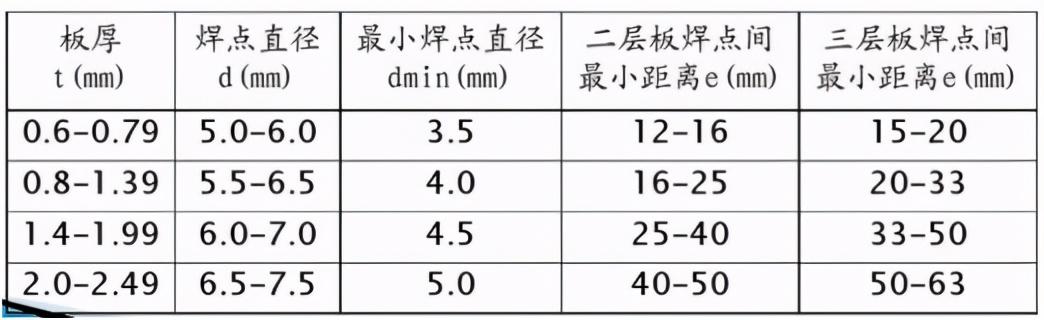

Distance between resistance solder joints

In practical applications, when welding small parts, the data in the table below can be referred to.

When welding large-sized parts, the distance between points can be appropriately increased, generally not less than 40-50mm. For non stressed parts, the distance between welding points can be enlarged to 70-80mm.

Plate thickness t, solder joint diameter d, minimum solder joint diameter dmin, and minimum distance e between solder joints. If the plate is a combination of different thicknesses, select according to the thinnest plate.

Number of layers and material thickness ratio of resistance welding sheet metal

The sheet metal for resistance spot welding is generally 2 layers, with a maximum of 3 layers. The thickness ratio of each layer of the welded joint should be between 1/3 and 3.

If it is necessary to weld a three-layer board, the material thickness ratio should be checked first. If it is reasonable, welding can be carried out. If it is not reasonable, process holes or process notches should be considered. For two-layer welding, the welding points should be staggered.

Sheet metal processing technology - Connection methods: This mainly introduces the connection methods of sheet metal during the processing, including rivet riveting, welding (as mentioned above), hole drawing riveting, and TOX riveting.

Rivet riveting: This type of rivet is commonly referred to as a pull rivet, which involves riveting two pieces of sheet metal together through a pull rivet. The common riveting shapes are shown in the figure:

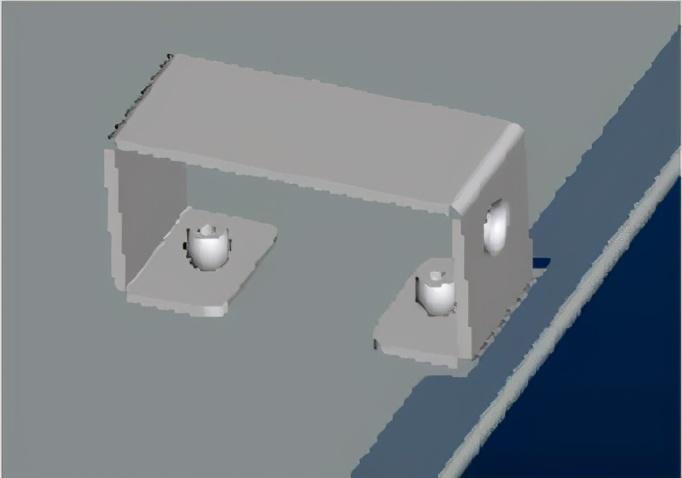

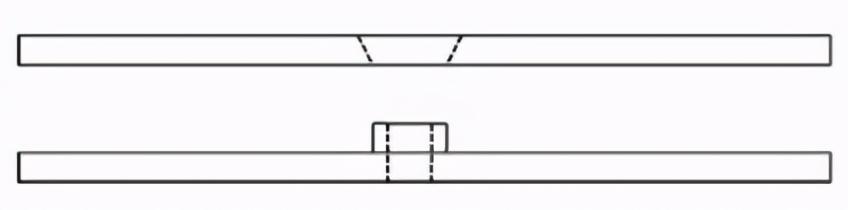

2. Welding (as mentioned earlier) 3. Drawing and riveting: One part is a drawing hole, and the other part is a countersunk hole, which is made into an inseparable connecting body through riveting.

Superiority: The extraction hole and its corresponding sinking hole have positioning function. The riveting strength is high, and the efficiency of riveting through molds is also relatively high.

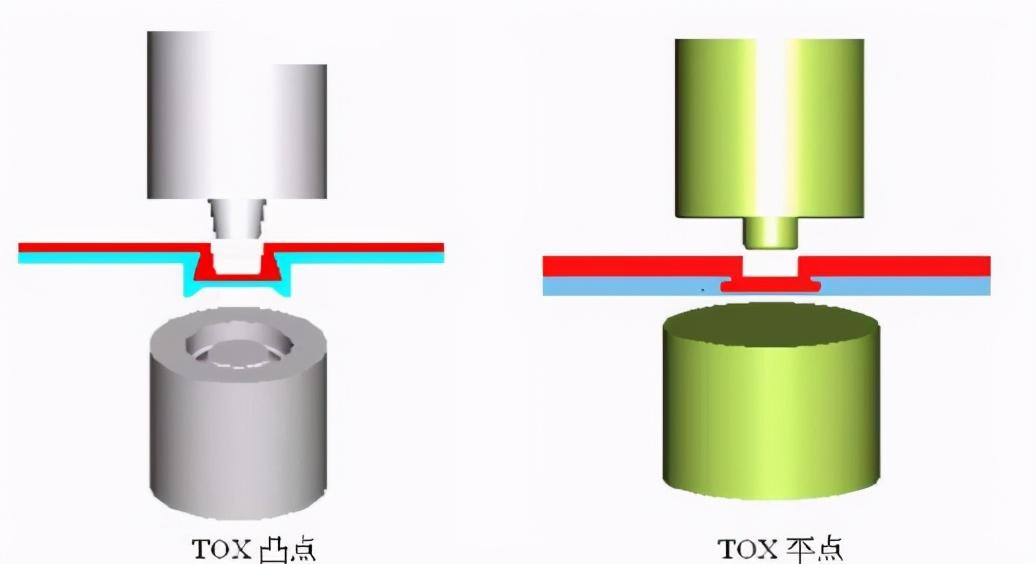

4. TOX riveting: Press the connected part into the concave mold through a simple convex mold. Under further pressure, the material inside the concave mold flows outward. The result is a circular connection point without any edges or burrs, which does not affect its corrosion resistance. Even for plates with a coating or spray paint layer on the surface, the original rust and corrosion resistance characteristics can be retained because the coating and paint layer can also retain the original rust and corrosion resistance characteristics, as the coating and paint layer also deform and flow together. The material is squeezed towards both sides and into the plate next to the concave mold, forming TOX connection dots. As shown in the following figure:

Sheet metal processing technology - Surface treatment can provide anti-corrosion protection and decorative effects on the surface of sheet metal. The common surface treatments for sheet metal include powder spraying, electrogalvanizing, hot-dip galvanizing, surface oxidation, surface drawing, screen printing, etc.

Before surface treatment of sheet metal, oil stains, rust, welding slag, etc. should be removed from the surface of the sheet metal.

Powder spraying: There are two types of surface spraying for sheet metal: liquid and powder paint. The commonly used one is powder paint. By spraying powder, electrostatic adsorption, high-temperature baking and other methods, a layer of various colors of paint is sprayed on the surface of the sheet metal to beautify the appearance and increase the anti-corrosion performance of the material. It is a commonly used surface treatment method.

Note: There may be some color difference in the colors sprayed by different manufacturers, so sheet metal of the same color on the same equipment should be sprayed from the same manufacturer as much as possible.

2. The surface galvanizing of galvanized and hot-dip galvanized sheet metal is a commonly used surface anti-corrosion treatment method, and can play a certain role in beautifying the appearance. Galvanization can be divided into electrogalvanizing and hot-dip galvanizing.

The appearance of electrogalvanizing is relatively bright and flat, with a thin galvanized layer, which is commonly used.

The hot-dip zinc coating is thicker and can produce an iron zinc alloy layer, which has stronger corrosion resistance than electrogalvanizing.

3. Surface oxidation: This mainly introduces the surface anodizing of aluminum and aluminum alloys.

The surface anodizing of aluminum and aluminum alloys can be oxidized into various colors, providing both protective and decorative effects. At the same time, an anodic oxide film can be formed on the surface of the material, which has high hardness and wear resistance, as well as good electrical insulation and thermal insulation properties.

4. Surface wire drawing: Place the material between the upper and lower rollers of the wire drawing machine, with a sand belt attached to the rollers. Driven by a motor, the material passes through the upper and lower sand belts, leaving marks on the surface of the material. The thickness of the marks varies depending on the type of sand belt, and their main function is to beautify the appearance. The surface treatment method of wire drawing is generally considered for aluminum materials.

5. Screen printing is a process of printing various markings on the surface of materials. There are generally two methods: flat screen printing and transfer printing. Flat screen printing is mainly used on general flat surfaces, but if there are deeper pits, transfer printing is needed.

Silk screen printing requires a silk mold.

Sheet metal processing accuracy reference attachment:

GBT13914-2002 Dimensional tolerances for stamped parts

GBT13915-2002-T Stamping Parts Angle Tolerance

GB-T15005-2007 Stamped parts - Limiting deviations without specified tolerances

GB-T 13916-2002 Stamped parts - Shape and position without specified tolerances

The ability of commonly used sheet metal processing equipment and the processing range of common sheet metal equipment

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque