In modern manufacturing, CNC pipe processing plays a critical role in industries ranging from aerospace to automotive and construction. As a leading CNC Machining service provider, EMAR specializes in delivering high-precision, customized solutions for metal pipes. This article explores the technical advantages, applications, and EMAR's capabilities in this field.

What Is CNC Pipe Processing?

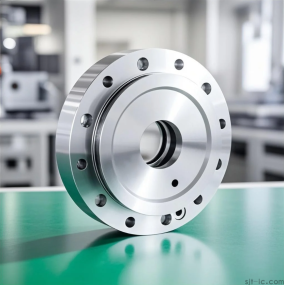

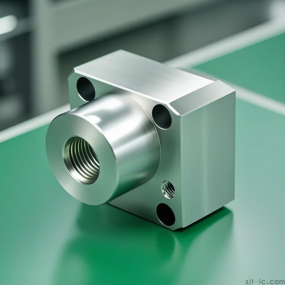

CNC pipe processing refers to the use of computer-controlled machines to cut, drill, bend, or shape metal pipes with micron-level accuracy. Unlike traditional methods, CNC technology ensures repeatability, complex geometries, and tight tolerances—essential for critical applications like hydraulic systems and structural frameworks.

Key Advantages of CNC Pipe Machining

- Precision: Achieve ±.01mm tolerances for leak-proof fittings.

- Material Versatility: Process stainless steel, aluminum, titanium, and exotic alloys.

- Efficiency: Reduce waste with optimized nesting and automated toolpaths.

EMAR's CNC Pipe Processing Capabilities

At EMAR, we combine advanced 5-axis CNC machines with ISO 9001-certified workflows to deliver:

- End-to-end solutions: From CAD design to post-processing (deburring, polishing).

- Large-diameter capacity: Handle pipes up to 500mm in diameter.

- Industry-specific expertise: Medical-grade finishes for bio-compatible applications.

Applications Across Industries

Our CNC pipe machining services support:

- Oil & Gas: High-pressure pipeline components.

- Automotive: Exhaust systems and fuel lines.

- Architecture: Customized structural elements.

Partner with EMAR for reliable, precision-engineered pipe solutions. Contact our team to discuss your project requirements today.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque