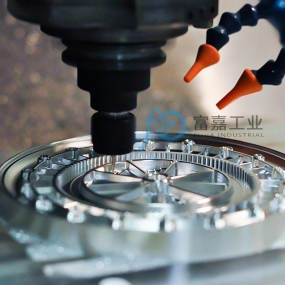

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC Machining parts, metal stamping parts, and sheet metal processing. The company respects the corporate spirit of "down-to-earth, hard work, and responsibility", and with integrity, win-win, and innovative business philosophy, creates a good corporate environment. With a new management model, perfect technology, thoughtful service, and excellent quality as the foundation of survival, we always adhere to the principle of putting customers first and serving them wholeheartedly, and insist on using our own services to impress customers.

Five deformations in the process of metal stamping parts

1. Stereoscopic pressing: redistributing the volume and transferring the material to change the shape or height thickness of the billet.

2. Bending: Transforming a flat sheet metal into a bent part, further altering the shape of the bent part. There are bends, twisted edges, etc.

3. Rolling: Stamping a flat billet into a hollow part of the desired shape, or further changing the size of the hollow part.

4. Forming: Using local deformations of various properties to change the shape of a workpiece or billet. Belonging to forming deformation include undulating forming, flanging, necking, bulging, rounding, and shaping.

5. Cutting and punching: not sealing or not sealing to separate one part of the material from another. This type of method includes material cutting, punching, edge cutting, cutting, sectioning, and cutting.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque