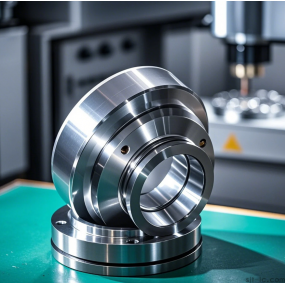

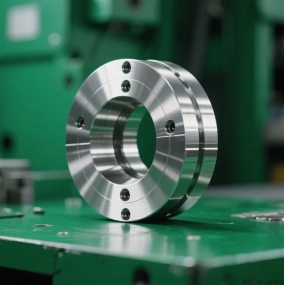

When a customer inquires, it is crucial to provide a quick and accurate quotation, taking into account various costs, profits, and other calculations when quoting. This mature stamping parts manufacturer actually has their own formulas. Let's take a brief look at how to calculate mold quotes and Metal Stamping parts product quotes.

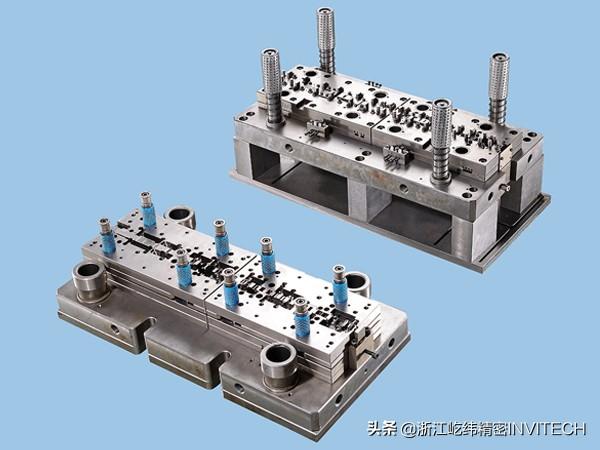

The mold quotation can be summarized as the following formula: reasonable and accurate mold=material cost fee+process design fee+processing fee+value-added tax paid+assembly and debugging fee+packaging and transportation fee

The above content is relatively fixed with less fluctuation, and various expenses can be directly calculated. Based on the above formula, using office software and editing the formula into a table, an accurate quotation table can be generated.

Product quotation formula: Part precision quotation=raw material cost - waste income+delegated parts+machine loss+labor cost+various management fees+required profit+packaging fee+transportation fee+total mold sharing fee+value-added tax

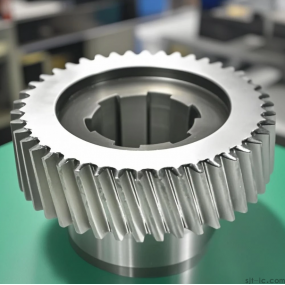

Control from multiple aspects such as raw material prices, material utilization, thickness, and step spacing, and then obtain the summarized product cost value. Of course, in addition to the materials themselves, there are also costs including packaging fees, surface treatment fees, and so on.

Zhejiang Yiwei Precision has been focusing on high-precision mass production of 100/10000 level components for 13 years, automated production and assembly, supporting mold development and design, providing one-stop services, and providing cost-effective stamping and stretching solutions that meet your needs. Welcome to consult.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque