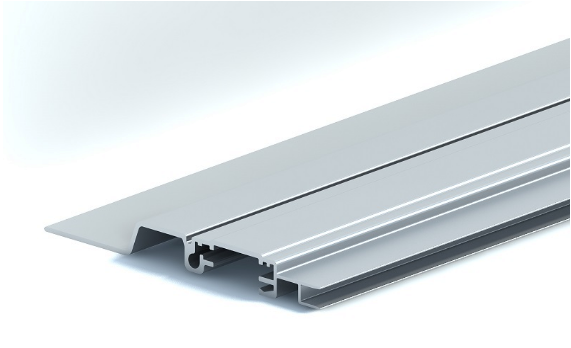

Generally speaking, aluminum profile processing includes aluminum profile extrusion processing, surface treatment, and deep processing. Perhaps you have provided the manufacturer with the drawings, and the manufacturer will soon be able to quote you the price. So how is the price of aluminum profile processing calculated?

If it's just simple extrusion processing, the price composition is very simple, just the aluminum ingot price+processing fee. The price of one ton of aluminum profiles is calculated by adding the price of aluminum ingots on that day to the processing fee per ton of aluminum profiles.

If it is aluminum profile extrusion+surface treatment, which means you only need to buy materials with good surface treatment, then the price is also relatively easy to calculate, including aluminum ingot price+extrusion processing fee+surface treatment processing fee. Our industrial aluminum profile manufacturers generally use anodizing for surface treatment. The price of natural color oxidation is about 1000 yuan/ton higher than that of substrate, and the price of colored oxidation is higher.

If aluminum profiles are extruded, surface treated, and deeply processed, the cost of processing these types of aluminum profiles together would be more complex. First, calculate the price of the materials from the first two steps, and then calculate the cost of deep processing. Generally, deep processing of aluminum profiles involves steps such as sawing, drilling, threading, milling, etc. Sawing will result in losses, so the cost of deep processing must include losses, and then the cost of sawing, drilling, tapping, and milling will be added up. Finally, there is a packaging fee. Generally, deep processed products require more stable packaging, and some packaging methods are more complex, so a certain packaging fee is charged according to packaging requirements.

Some aluminum profiles are processed using CNC machine tools, and the cost of deep processing is calculated based on working hours, which means that the more difficult and time-consuming the processing, the higher the processing cost. For example, some aluminum profiles require honeycomb holes to be drilled, and hundreds or even thousands of holes to be drilled on a single aluminum profile, which is very time-consuming and the processing cost is also relatively high.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque