The editor will organize a lot of practical knowledge methods and hot news for everyone. Everyone should pay more attention and better content will be presented to you

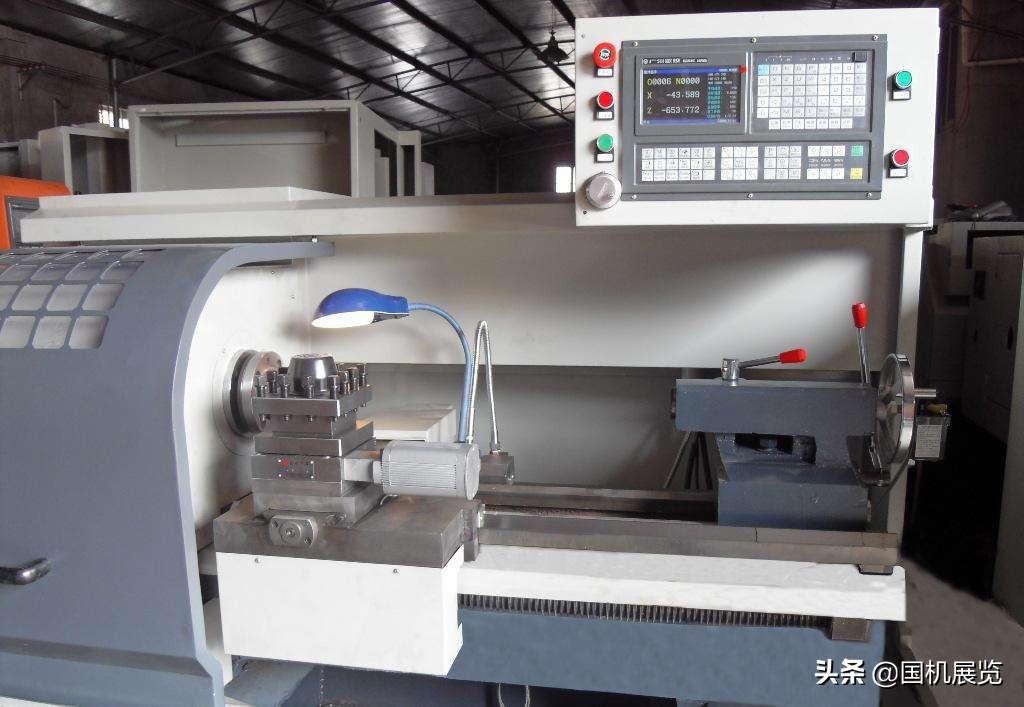

On a CNC lathe, four standard threads can be turned: metric, inch, modulus, and radial control. Regardless of which type of thread is turned, the lathe spindle and tool must maintain a strict motion relationship: that is, for every revolution of the spindle (i.e., every revolution of the workpiece), the tool should move a uniform lead distance of the workpiece. Through the analysis of ordinary threads, we aim to enhance our understanding of ordinary threads in order to better process them.

1、 Dimensional analysis of ordinary threads

The CNC lathe requires a series of dimensions for processing ordinary threads, and the calculation and analysis of the dimensions required for processing ordinary threads mainly include the following two aspects:

1. Diameter of workpiece before thread machining

Considering the expansion of the thread profile during thread processing, the diameter of the workpiece before thread processing is d/d-0.1p, which means the major diameter of the thread is reduced by 0.1 pitch. Generally, based on the small deformation capacity of the material, it is taken as 0.1 to 0.5 smaller than the major diameter of the thread.

2. Thread machining feed amount

The amount of thread feed can refer to the bottom diameter of the thread, which is the final feed position of the thread cutter.

The minor diameter of the thread is: major diameter -2 times the tooth height; Tooth height=0.54p (p is pitch)

The feed amount for thread machining should be continuously reduced, and the specific feed amount should be selected based on the tool and working material.

2、 Installation and alignment of ordinary thread cutting tools

If the installation of the turning tool is too high or too low, when the cutting tool reaches a certain depth, the rear cutting surface of the turning tool presses against the workpiece, increasing friction and even bending the workpiece, causing the phenomenon of biting the tool; If it is too low, the chips are not easily discharged, and the radial force of the turning tool is towards the center of the workpiece. In addition, the gap between the horizontal screw and the nut is too large, causing the cutting depth to automatically deepen, thereby lifting the workpiece and causing cutting. At this point, the height of the turning tool should be adjusted in a timely manner to ensure that its tip is at the same height as the axis of the workpiece (using the tip of the tailstock to align the tool). During rough and semi precision turning, the tool tip position is about 1% higher than the center of the workpiece (d represents the diameter of the workpiece being processed).

The workpiece cannot be firmly clamped, and the rigidity of the workpiece itself cannot withstand the cutting force during turning, resulting in excessive deflection and changing the center height between the turning tool and the workpiece (the workpiece is raised), causing a sudden increase in cutting depth and tool gnawing. At this time, the workpiece should be firmly clamped, and tailstock tips can be used to increase the rigidity of the workpiece.

The tool alignment methods for ordinary threads include trial cutting method and automatic tool alignment instrument. The tool can be directly used for trial cutting, or the workpiece zero point can be set with G50, and the workpiece zero point can be set with workpiece movement for tool alignment. The requirements for tool alignment in thread machining are not very high, especially there are no strict restrictions on tool alignment in the z-direction, which can be determined according to programming machining requirements.

3、 Programming and machining of ordinary threads

In current CNC lathes, there are generally three processing methods for thread cutting: g32 straight cutting method, g92 straight cutting method, and g76 oblique cutting method. Due to different cutting methods and programming methods, machining errors also vary. We need to carefully analyze the operation and use, and strive to process high-precision parts.

1. The G32 straight cutting method, due to the simultaneous operation of both cutting edges, has a high cutting force and is difficult to cut. Therefore, during cutting, both cutting edges are prone to wear. When cutting threads with larger pitches, due to the larger cutting depth, the blade wear is faster, resulting in errors in the thread pitch diameter; However, its processed tooth shape accuracy is relatively high, so it is generally used for small pitch thread processing. Due to the fact that tool movement and cutting are all completed through programming, the machining program is relatively long; Due to the easy wear of the cutting edge, frequent measurement is necessary during processing.

2. The G92 straight cutting method simplifies programming and improves efficiency compared to the G32 instruction.

3. The G76 oblique cutting method, due to its single edge machining, is prone to damage and wear of the cutting edge, resulting in an uneven threaded surface and changes in the tool tip angle, resulting in poor tooth shape accuracy. However, due to its single edge operation, the tool load is small, chip removal is easy, and the cutting depth is decreasing. Therefore, this machining method is generally suitable for machining large pitch threads. Due to its easy chip removal and good cutting conditions, this machining method is more convenient when the thread accuracy requirements are not high. When processing high-precision threads, two tool machining can be used, which involves rough turning using the G76 machining method first and then precision turning using the G32 machining method. But it is important to ensure that the starting point of the tool is accurate, otherwise it is easy to buckle randomly and cause parts to be scrapped.

4. After the thread processing is completed, the quality of the thread can be judged and measures can be taken in a timely manner by observing the thread profile. When the top of the thread is not pointed, increasing the cutting amount of the tool will actually increase the major diameter of the thread, which depends on the plasticity of the material. When the top of the thread has been pointed, increasing the cutting amount of the tool will proportionally reduce the major diameter. Based on this characteristic, the cutting amount of the thread should be treated correctly to prevent scrapping.

4、 Testing of ordinary threads

For general standard threads, thread ring gauges or plug gauges are used for measurement. When measuring external threads, if the thread is" Over End; The ring gauge is precisely screwed in, while"a; End stop; If the ring gauge cannot be rotated, it indicates that the processed thread meets the requirements, otherwise it is unqualified. When measuring internal threads, use a thread plug gauge and use the same method for measurement. In addition to measuring with a thread ring gauge or plug gauge, other measuring tools can also be used for measurement. The thread diameter can be measured with a thread micrometer, and the tooth thickness can be measured with a tooth thickness vernier caliper for trapezoidal thread diameter and worm pitch diameter. A measuring needle can be used to measure the thread diameter using the three needle measurement method.

The 15th China International Machine Tool Exhibition (CIMES2020) will be held from May 18-22, 2020 at the new building of the China International Exhibition Center (Shunyi) in Beijing. We welcome you to come and guide us.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque