The importance of high hardness of stamping die materials

Stamping mold is a commonly used mold in industrial production, which is formed by stamping on metal sheets through the mold to achieve the desired shape and size. Stamping molds are important tools for manufacturing various metal products, such as components for automobiles, machinery, electronics, and other products. Therefore, the quality and performance of stamping molds are crucial for the quality and performance of products. The hardness of stamping die materials is one of the important factors determining their quality and performance. Higher material hardness can ensure the wear resistance and durability of the mold, allowing it to be used for a long time in production without failure. At the same time, material hardness also affects the accuracy and efficiency of stamping forming, as molds with high hardness can better maintain their shape and size, thereby better ensuring the quality of the finished product. Therefore, selecting appropriate stamping die materials and ensuring their high hardness is an important step in manufacturing high-quality stamping dies.

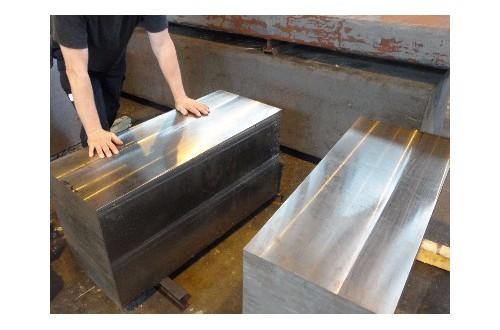

Common stamping die materials

At present, the commonly used stamping die materials include the following:

1. High speed steel (HSS)

High speed steel is a high-quality steel with characteristics such as high strength, high hardness, and high wear resistance.

It is one of the ideal materials for manufacturing high-precision and high-quality stamping molds. The hardness of high-speed steel is usually between 60~70HRC, which can meet the requirements of most stamping molds. At the same time, high-speed steel also has good processing performance, and its hardness and wear resistance can be improved through processes such as heat treatment.

2. Alloy tool steel

Alloy tool steel is a type of tool steel containing alloying elements, which has high hardness and wear resistance. It is usually used to manufacture large and complex stamping molds because its hardness can reach 70-80HRC, making it more suitable for manufacturing high-quality molds than high-speed steel.

However, the processing performance of alloy tool steel is relatively poor, requiring higher processing difficulty and cost.

3. Special steel

In addition to high-speed steel and alloy tool steel, there are also some special steel materials that can be used to manufacture stamping molds, such as cold work mold steel, hot work mold steel, stainless steel, etc. These materials have specific characteristics and uses, and suitable materials need to be selected based on specific production requirements.

Comparison Table for Hardness of Stamping Mold Materials

The following is a commonly used hardness comparison table for stamping die materials: | Material Name | Hardness (HRC) | | -------- | -------- | 45 # Steel | 25-30 | | 40Cr Steel | 28-35 | Cr12MoV Steel | 55-60 | H13 Steel | 45-50 | SKD11 Steel | 60-65 | SKH51 Steel | 60-70 | DC53 Steel | 62-67 | ASP60 Steel | 62-68 | M2 Steel | 60-65 | M42 Steel | 65-70 | It should be noted that different stamping die materials have different hardness requirements for different production needs. When selecting materials, it is necessary to determine the most suitable material and hardness based on the actual situation.

How to improve the hardness of stamping die materials?

In addition to selecting suitable materials, the hardness of stamping die materials can also be improved through the following methods:

1. Heat treatment

Heat treatment is a commonly used method to improve the hardness of materials. By controlling the heating and cooling processes of materials, their crystal structure and properties can be changed, thereby improving their hardness and wear resistance. Common heat treatment methods include quenching, tempering, normalizing, etc.

2. Surface treatment

Surface treatment is a method of improving the hardness and wear resistance of a material by altering its surface structure and properties. Common surface treatment methods include nitriding, carbonization, nitriding, etc.

3. Coating treatment

Coating treatment is a method of coating a material surface with a special layer to improve its hardness and wear resistance.

Common coating materials include titanium, nitrides, carbides, etc. It should be noted that although the above methods can improve the hardness and wear resistance of the material, they can also have an impact on other properties of the material, such as toughness and toughness. Therefore, when selecting and using these methods, it is necessary to comprehensively consider the actual situation.

conclusion

The hardness of stamping die materials is an important factor in manufacturing high-quality stamping dies. Choosing appropriate materials and improving their hardness through appropriate methods can ensure that the mold will not fail during long-term use in production, while also improving the accuracy and efficiency of stamping forming. In the process of selecting and using stamping die materials, it is necessary to comprehensively consider the actual situation and choose the most suitable materials and methods.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque