With the shift in environmental awareness and people's consumption needs, there has been a growing demand for metal tableware among many people. Our common metal tableware uses edible 304 stainless steel, which combines safety, environmental friendliness, and aesthetics. So how was this type of tableware produced?

The raw material for stainless steel tableware is definitely stainless steel, which is cut and cut on stainless steel plates. Taking stainless steel spoons as an example, it is necessary to use a laser cutting machine to cut and cut materials on the stainless steel plate according to the size of the spoon; The next steps are similar to the ancient process of making gold and silver jewelry. The cut material is continuously forged, and finally the entire processing process is completed by using a stamping die for stamping.

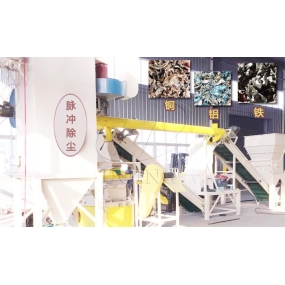

The utensils used in our cafeteria are actually processed using the same method as spoons. Of course, the production process of all metal tableware has similarities, which is to first use a laser cutting machine for cutting, and for those that need to be punched, they need to be punched on the board first; Then proceed with stamping forming.

laser cutting machine

laser cutting machine

It is worth noting that the current cutting process has greatly improved compared to before. Laser cutting machines can cut and align themselves according to the drawings, reducing material waste and lowering production costs. Design and complete the required cutting requirements according to the drawings; Knowing the production process of metal tableware makes the food delicious.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque