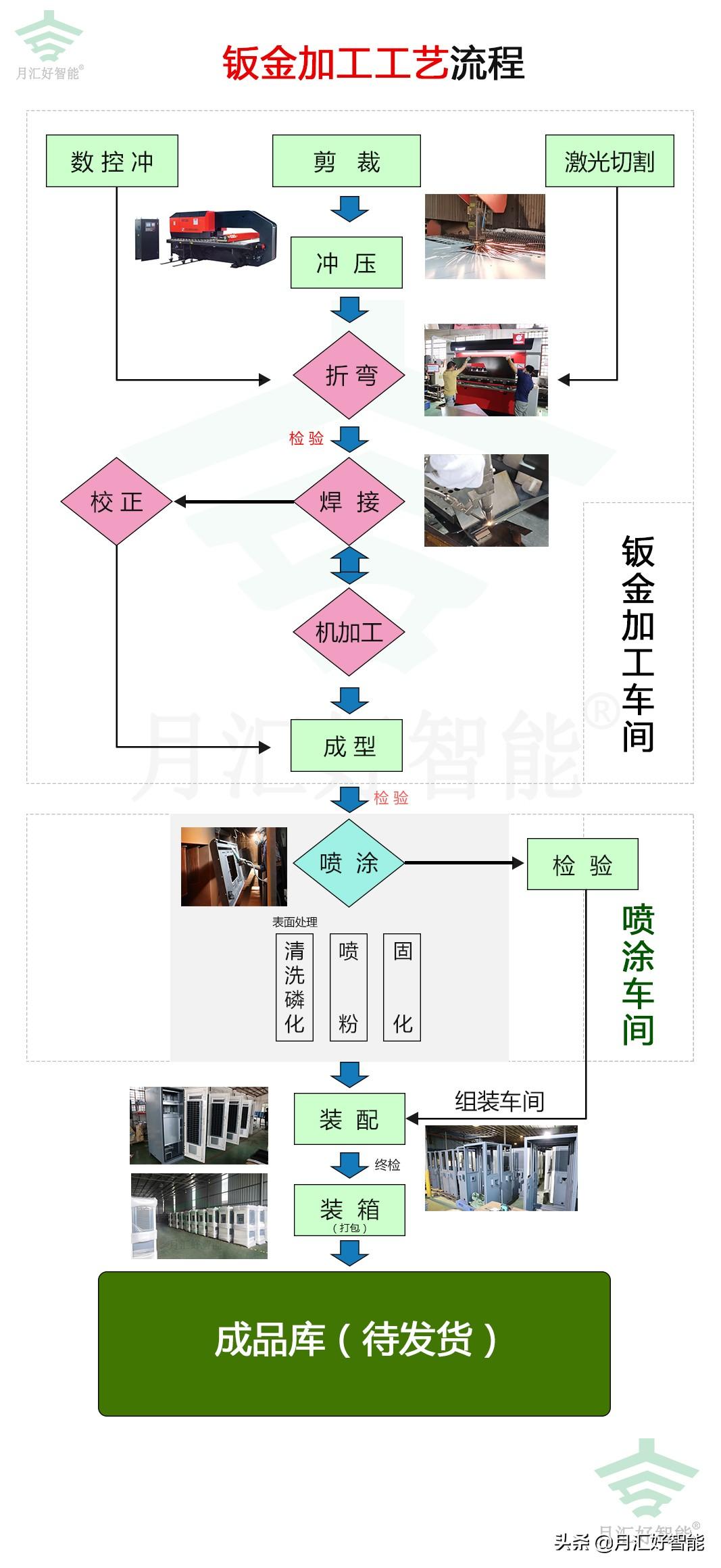

Summary: Drawing Sheet Metal Processing Surface Spraying Assembly Forming 1 The sheet metal processing factory designs product drawings based on the requirements of the box or according to the drawings provided by the customer. 2. The sheet metal processing workshop performs cutting (laser cutting, CNC punching, cutting, etc.) according to the drawings; CNC bending -> Stamping -> Machining -> Welding/Forming -> Polishing -> Semi finished product 3 Spray painting processing and assembly workshop: Spray painting pre-treatment (water washing, phosphating, etc.) based on the previous semi-finished product; Online powder coating or spray painting -> Curing -> Assembly -> finished product

Sheet metal processing process flowchart

The above is a rough process flow chart for sheet metal processing that has been collected on a monthly basis for reference only. If there is a need to reprint, please indicate the source with a note. Thank you!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque