Emma Technology Co., Ltd. is a leading enterprise specializing in the customization of precision hardware accessories. We have years of industry experience and rich professional knowledge, committed to providing customers with the highest quality customized services. As a highly innovative and technology driven company, we provide customized solutions to meet the specific needs of customers in various industries. In this article, we will provide a detailed introduction to our company's service scope, customization process, and our advantages in precision hardware accessory customization.

As a customization expert in precision hardware accessories, Emma Technology Co., Ltd. provides a wide range of customization services, covering a variety of hardware accessories. We cooperate with customers to manufacture various high-quality and highly precise hardware accessories using advanced production equipment and technology according to their needs and specifications. We are proficient in various manufacturing processes such as CNC Machining, turning, milling, stamping, sheet metal, etc., and can meet customer customization requirements for various complex shapes and strict dimensions of accessories. Whether it's small-scale production or large-scale customization, we can provide high-quality solutions.

Our customization process is carefully designed to ensure that customer needs are met to the greatest extent possible. Firstly, our team conducts detailed communication and requirement analysis with clients to understand their project objectives and specific requirements. Next, our engineering team will develop and design technical solutions, using advanced software and tools for simulation and optimization. After obtaining customer recognition, we will start manufacturing samples and conduct strict quality control and testing to ensure they meet customer requirements. Once the samples pass the validation, we will start mass production and deliver according to the plan.

Emma Technology Co., Ltd. has a series of unique competitive advantages in the field of precision hardware parts customization. Firstly, we have an experienced and skilled team with years of practical experience in the hardware processing industry. Our engineering team is familiar with international standards and industry best practices. Secondly, we have advanced production equipment and technology to ensure the manufacture of high-quality and high-precision hardware accessories. We constantly update our equipment and technology to keep pace with the development of the industry.

In addition, we focus on quality control and performance testing, and strictly implement the quality management system throughout the entire manufacturing process. Our accessories undergo strict inspection and testing to ensure they meet international standards and specific customer requirements. We also provide comprehensive after-sales service, respond promptly to customer feedback, and provide technical support and improvements as needed.

In short, Emma Technology Co., Ltd. is your ideal partner for customizing precision hardware accessories. We have rich experience, advanced equipment and technology, and can provide customers with high-quality and high-precision customized services. We are committed to understanding customer needs and providing the best solutions. If you have any customized needs for precision hardware accessories, please contact us and we will be happy to serve you.

In modern industry, precision hardware molds play a crucial role. They are widely used in various industries, including automotive manufacturing, electronic equipment, aerospace, medical devices, and other fields. The production of precision hardware molds is a complex and delicate process that requires a high level of technology and professional knowledge. This article will introduce the production process of precision hardware molds, including detailed information on design, processing, debugging, and other aspects.

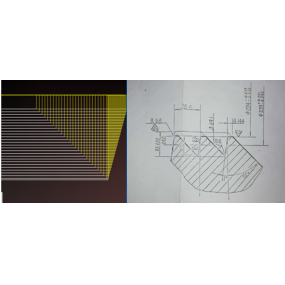

Firstly, the production of precision hardware molds begins in the design phase. Designers create three-dimensional drawings of the mold based on customer requirements and product requirements. This requires the use of computer-aided design software, such as CAD (computer-aided design) or CAM (computer-aided manufacturing) tools. The design phase is crucial because good design can greatly improve the production efficiency and product quality of molds.

Once the design phase is completed, the next step is the process of material selection and processing. For the production of precision hardware molds, commonly used materials include steel, iron, and aluminum alloys. The selection of materials depends on the requirements of the product and the usage conditions of the mold. In general, steel has high strength and wear resistance, making it very suitable for manufacturing precision hardware molds.

During the processing, the selected material needs to be cut into the desired shape first. This is usually achieved through CNC cutting machines to ensure cutting accuracy and consistency. Then, the cut material needs to be precision machined to form various parts of the mold. This may include processes such as milling, turning, and drilling. The entire processing process requires strict operation and monitoring to ensure that the size and quality of the mold meet the requirements.

After completing the processing, the next stage is the assembly and debugging of the mold. Assemble the various components together and conduct preliminary debugging and inspection. The purpose of this stage is to ensure that the various parts of the mold can work in coordination and achieve the expected results. If necessary, some minor adjustments and modifications can be made to achieve higher accuracy and stability.

Finally, after debugging and testing, the precision hardware mold can be put into use. But this does not mean the end of the manufacturing process, maintenance and upkeep of the mold are equally important. Regular maintenance and repair can extend the service life of molds and maintain their efficient operation. In addition, with the continuous development of technology and changes in product demand, molds may need to be updated and improved.

To sum up, the production of precision hardware molds is a complex and meticulous process that requires a high level of technology and professional knowledge. From design to processing and debugging, every step requires careful operation and monitoring. A well made precision hardware mold can greatly improve production efficiency and product quality, which is crucial for modern industry.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque