Choosing a suitable CNC Machining manufacturer or service provider is the key to ensuring that you receive high-quality machining services. Here are some suggestions to help you make a choice:

1. Quality and experience: Choose manufacturers or service providers with good reputation and rich experience. You can view their customer reviews, project cases, or visit their production facilities to understand their strength and quality control capabilities.

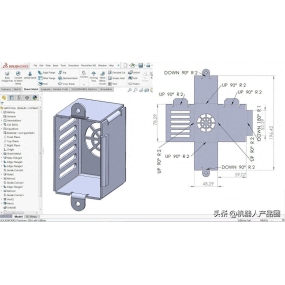

2. Technical ability: Understand the technical ability of CNC machining manufacturers, including the equipment, software, and processes they possess. Ensure that they use advanced technology and equipment to provide high-precision and high-efficiency processing services.

CNC machining

3. Applicable materials and processing capabilities: Ensure that CNC machining manufacturers have processing capabilities and professional knowledge that are suitable for your needs. Understand if they have experience in processing the materials you need and can meet your specific requirements, such as size, shape, and surface requirements.

4. Delivery time and service response: Understand the manufacturer's delivery time and service response capabilities. When choosing, ensure that they can deliver on time and provide the ability to respond quickly and solve problems.

5. Cost effectiveness: Consider the cost-effectiveness of processing services, not just the price. Evaluate the balance between the manufacturer's price level and the quality and service they provide. Meanwhile, pay attention to hiding costs to avoid unnecessary additional expenses.

6. Communication and cooperation: Choose manufacturers or service providers who can cooperate with you and understand your needs. They should be able to communicate effectively with you and provide technical support and advice to achieve the best processing results.

The best way is to compare and evaluate multiple suppliers. By communicating and visiting potential manufacturers, you will be able to better understand their capabilities, reputation, and ability to adapt to your needs, thus making wise choices.

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC machining parts, metal stamping parts, and sheet metal processing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque