Sheet metal processing factories mainly design and process based on design drawings, and the processing technology will also vary depending on the design drawings. Each link of the process can be used as a part processing process, and now the most commonly used industrial machinery sheet metal processing.

1、 According to the drawings, carry out step-by-step process operations, or draw the part drawings of the sheet metal parts based on the physical shape provided by the customer. The main purpose is to display the parts to be processed according to the drawings.

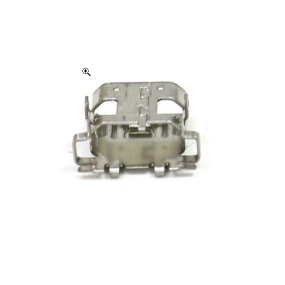

2、 According to the requirements for sheet metal parts and different materials, different cutting methods can be selected, usually including shearing machine cutting, punching machine cutting, CNC cutting, and laser cutting machine cutting. Because many sheet metal parts have high requirements for the accuracy and quality of laser cutting, the method used is laser cutting machine for cutting, in order to ensure quality and improve work efficiency.

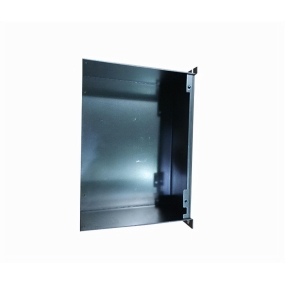

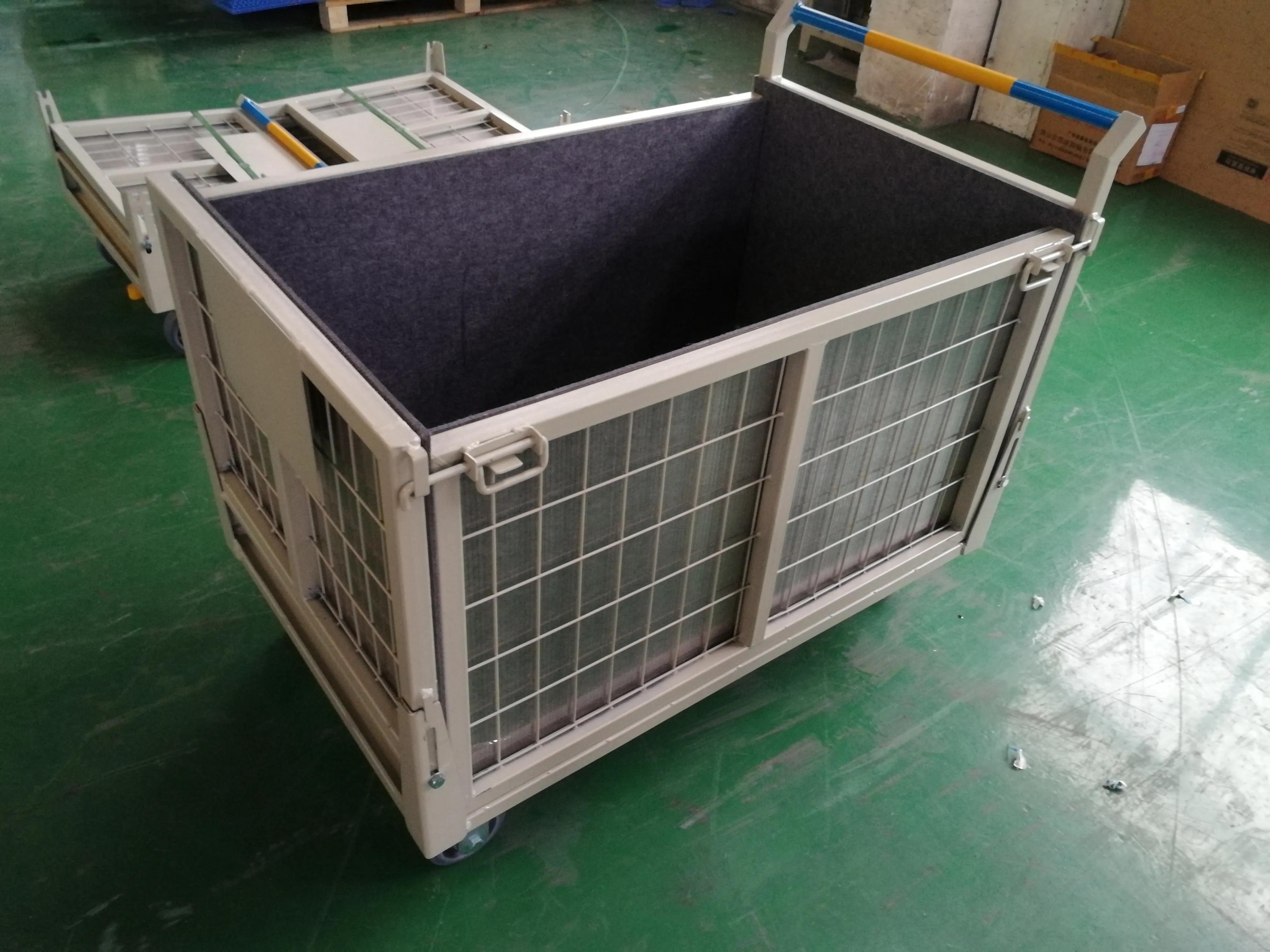

3、 Bending is the process of processing flat parts into three-dimensional parts, which requires a bending machine and corresponding bending molds to complete the operation. It also has a certain bending sequence, and its principle is to fold first without interference with the next tool, and then fold later if interference occurs. Currently, the main method used is CNC bending processing, which is not only to improve efficiency, but also to reduce labor commission and ensure quality improvement.

4、 Welding is the process of welding multiple parts together to achieve the purpose of processing, or welding the edges of individual parts to increase their strength. One of the crucial steps during welding is that good welding points will not produce welding slag or leave marks on the surface of sheet metal objects, and can be tested for water leakage. Nowadays, gas shielded welding, argon arc welding, spot welding, robot welding, etc. are commonly used.

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC Machining parts, metal stamping parts, and sheet metal processing.

1. Laser cutting series: processed according to customer's drawings. 2. Mechanical Shell Series: Large mechanical sheet metal structural components such as injection molding machines, automation, packaging, printing, ceramics, elevators, etc. 3. Box series: indoor and outdoor floor mounted chassis, automatic ticket machine chassis LED electronic display screen casing, etc. 4. Electrical cabinet chassis series: network communication cabinet, distribution cabinet, switch cabinet, junction box, control box, etc. 5. Medical equipment series: instrument cabinets, operating tables, medical beds, medical purification equipment, etc. 6. Decoration engineering series: aluminum ceiling, aluminum curtain wall, aluminum profile, stainless steel decoration engineering, etc. 7. Office supplies series: filing cabinets. 8. Public utility series: shell of automatic water dispenser, ATM teller machine body, bus waiting hall, intelligent garbage sorting and recycling bin. 9. Manufacturing of power electronic components; Manufacturing of industrial automatic control system devices; Manufacturing of hardware products; Manufacturing of communication equipment; Sales of metal products

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque