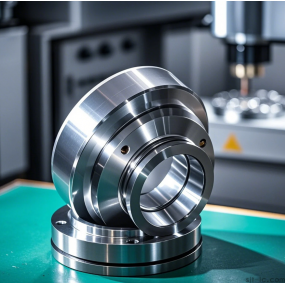

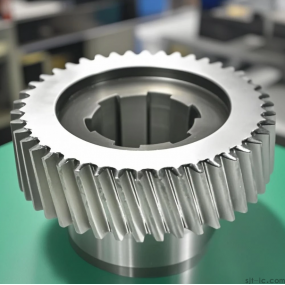

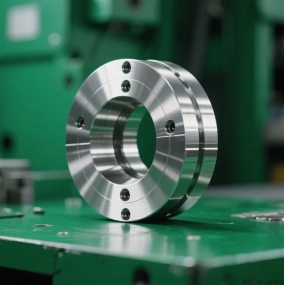

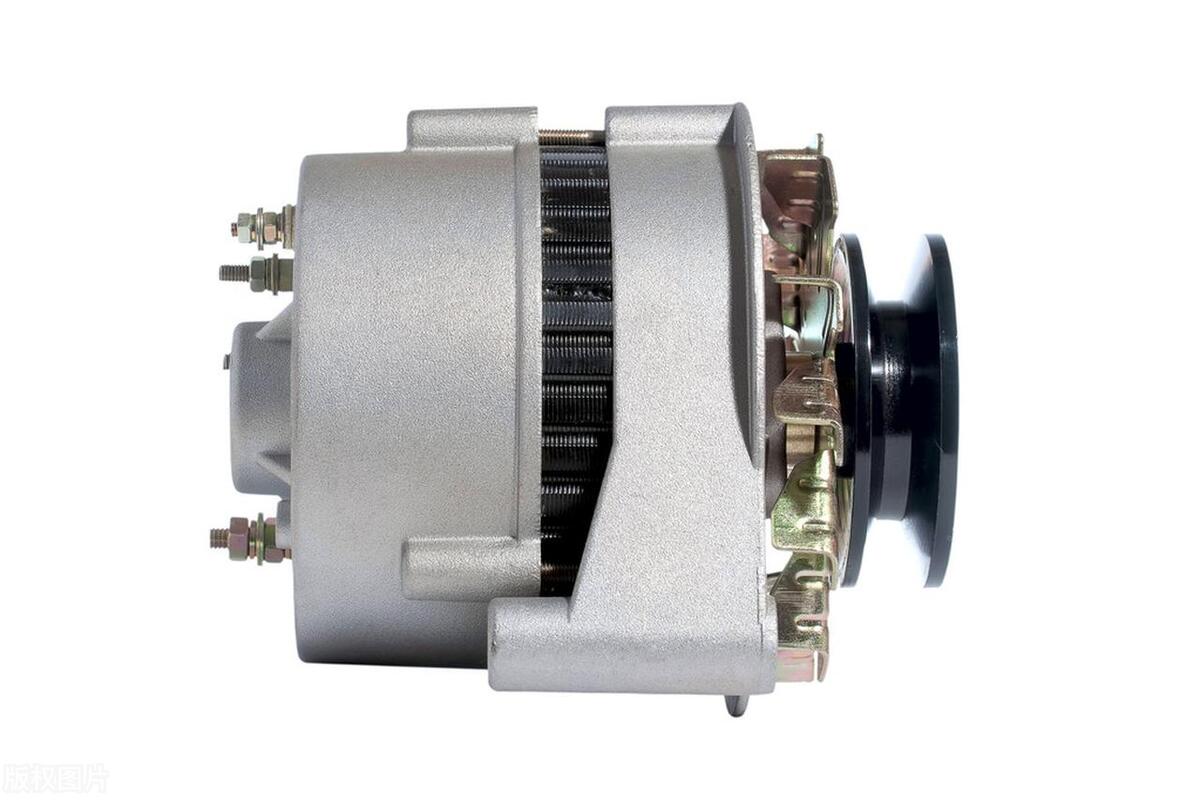

The motor housing is an important component of the motor, which mainly serves to protect the internal parts of the motor from external environmental influences and also plays a role in heat dissipation. There are several common ways to process motor casings: casting method: Casting method is to pour liquid metal or alloy into a mold and solidify it by cooling to form the desired motor casing. This processing method can manufacture complex shaped shells with high production efficiency, but it requires a large amount of energy and materials. Stamping method: Stamping method is the use of a punch press to perform cutting, punching, bending and other processing operations on metal sheets, forming the required motor housing. This processing method can quickly produce large quantities of shells with relatively low costs, but cannot manufacture overly complex shapes. CNC Machining method: CNC machining method is the use of computer numerical control machine tools for precision machining of metal materials, which can produce complex shaped motor housings. This processing method requires the design of CAD drawings first, and then the machine tool is controlled by a program for processing, so the production efficiency is low, but the processing accuracy is high. Different processing methods have their own advantages and disadvantages, and choosing the appropriate processing method depends on the specific situation. Overall, the processing of motor casings requires consideration of various factors such as shape, material, and production efficiency to ensure the quality and performance of the final product.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque