How much do you know about industrial design technology? Metal Stamping and cold stamping technology are generally used to process metal sheets into shallow concave shapes or curved profiles. It has the characteristics of fast processing speed and high accuracy. It can be used to produce a variety of daily products, from car bodies to metal pallets.

High processing cost, high mold cost, and low to medium unit cost

Typical Applications: Automotive, Consumer Products, Furniture

Applicability · Large scale production

Processing quality · High quality, precise bending

Related processes: Deep drawing, Metal spinning, Bending forming

Processing cycle · Short cycle (1 second to 1 minute)

Process Introduction: Metal stamping is a metal processing method that is based on the plastic deformation of metal. It uses molds and stamping equipment to apply pressure to the sheet metal, causing plastic deformation or separation of the sheet metal, thereby obtaining parts (stamped parts) with certain shapes, sizes, and properties. Stamping technology plays an important role in the manufacturing process of automobile bodies.

Metal stamping can be used to process shallow concave metal shapes, and the processing requirements for molds are relatively high, and this process is only suitable for large-scale production. This process has high precision in processing and there is no significant change in material thickness. When the ratio between depth and diameter decreases, the machining process is very similar to deep drawing, and neither of these machining processes significantly reduces the thickness of the material.

Mass production of parts requires the comprehensive use of multiple forming and cutting processes based on progressive tools. A series of molds are essential in rapid processing. In the process of machining parts, sometimes a second operation is required on previously formed parts. Some parts may require 5 or more operations, which reflects the number of processes involved. This process can process metal sheets into cylindrical, conical, and hemispherical shapes. The frequent combination of stamping and pressing in the process provides a wide range of choices for the entire design, such as when machining flange edges, asymmetric hubs, and shapes with perforations, the distinctive features of this process are evident.

Technical Description

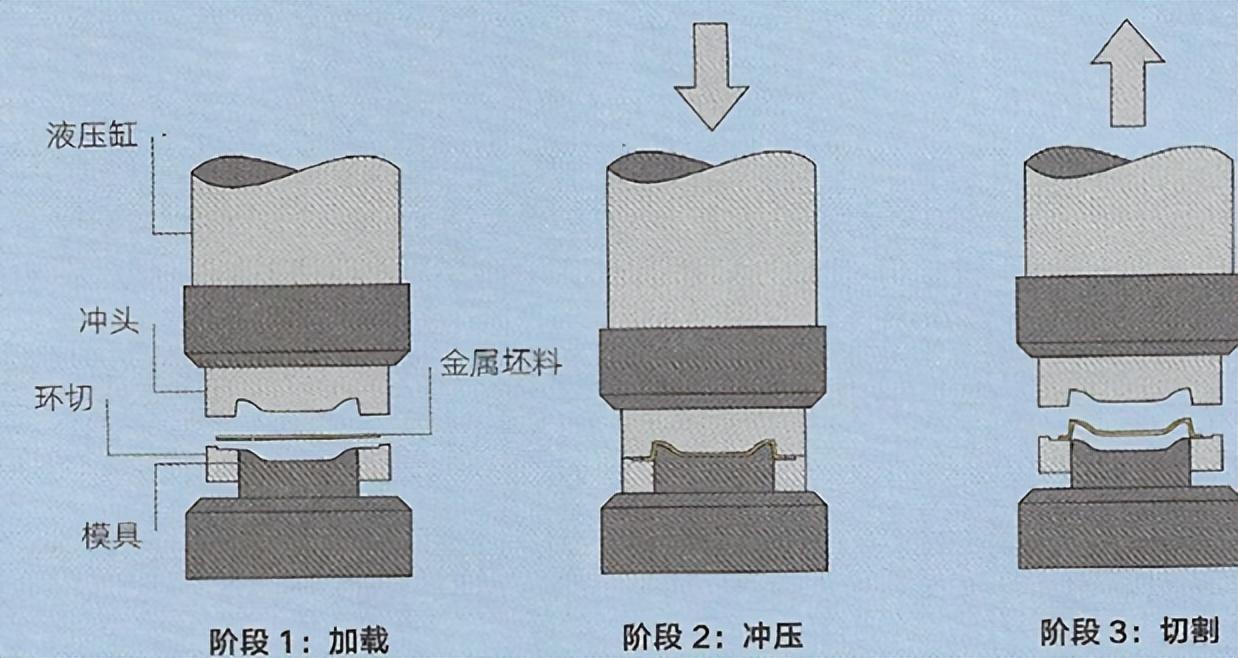

The specific process of metal stamping on a punch press is to transmit power to the punch through a hydraulic cylinder or mechanical device (such as a cam press). Generally, hydraulic cylinders are chosen because their pressure is evenly distributed throughout the entire stamping cycle, and those using mechanical devices also have a place in the metal processing industry.

Punches and molds are specialized and generally only perform a single operation of forming or punching. In operation, metal billets are usually loaded onto the workbench. Then clamp the punch and complete the forming process of the part in one stroke.

After the molding is completed, the stripper moves up and pushes out the part, at which point the part is removed. Sometimes part forming is a continuous process, and after processing, it also goes through a stamping process. This is commonly known as the continuous molding process.

Under these processing conditions, the processed metal parts are transferred to the next stage of processing. This process can be done manually or through transfer tracks. Most systems are automated and maintain high processing speeds. The next step may involve pressure processing, stamping, curling, or other secondary processing.

The typical application of stamping processing is very extensive. The vast majority of large-scale metal processing techniques in the automotive industry are stamping or extrusion, including body, door lining, and edging.

This process is used for the processing of metal camera bodies, mobile phones, TV casings, household appliances, and MP3 players. Kitchen and office equipment, tools, and knives also use this process. The external shape and internal structure of the parts can be processed using this process.

Small batch production of parts using related processes is achieved through sheet metal processing, metal spinning, or bending forming. These processes can produce shapes similar to metal stamping, but require high labor skills.

Although stamping and deep drawing processes are similar, there are still significant differences. When the depth of the part is greater than 1/2 of the diameter, the part must be elongated and the wall thickness reduced. This requires gradual and slow operation to avoid excessive stretching and tearing of the material.

Superplastic molding can produce larger and deeper parts using simple operations. However, this processing is limited to aluminum, magnesium, and titanium because it requires the material to have superplasticity.

The metal profile formed by processing quality combines the ductility and strength of the metal material of the parts, enhancing rigidity and brightness.

If the surface effect requirements are not particularly strict, the parts only need to be slightly deburred after deformation. Sandblasting is used to reduce surface roughness. Parts can also be further processed through powder coating, spray painting, or electroplating.

Design opportunities refer to the methods of quickly and accurately manufacturing shallow concave shapes using sheet metal. This technique can be used for circles, squares, and polygons.

Thin walled parts can be strengthened by adding ribs, which can also reduce weight and processing costs. Choosing appropriate molds can process profiles with composite curves and complex surfaces. A similar process to complete this task is sheet metal processing, but it requires workers with high technical skills. Soft molds can be applied to sheet metal processing and metal stamping. One side of this mold is made of rigid rubber, which can apply sufficient pressure to form a metal blank on the punch.

Design considerations: Stamping processing is carried out on a vertical axis. Therefore, the concave angle is formed in the second stamping. Secondary stamping includes pressure deformation, cutting extension, and curling.

The first stamping operation can only reduce the diameter of the defective material by 30%. Continuous operation can reduce the diameter by 20%. This means that the processing of some parts requires a certain number of continuous stamping.

In deep drawing technology, the process is often limited by the machining capacity of the machine. The size of the machine bed determines the size of the billet, and the stroke determines the stretching length. The processing cycle is determined by the stroke and the complexity of the parts.

The thickness of stamped stainless steel ranges from 0.4 to 2mm, and it is possible to process up to 6mm thick plates, but it is affected by the shape.

Many metal sheets can be processed through this process, such as carbon steel, stainless steel, aluminum, magnesium, bowl, copper, brass, and zinc.

The processing cost is relatively high due to the need for high-strength metal molds during processing. Semi rigid rubber molds have lower costs, but still require single-sided metal tools and are only suitable for small-scale production.

The processing cycle is very short, and 1 to 100 parts can be processed within 1 minute. Replacing and setting up molds requires a certain amount of time.

The labor cost is relatively low due to the high degree of automation. Polishing will significantly increase labor costs.

All waste materials can be recycled due to environmental impact. Metal stamping technology can be used to produce durable items.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque