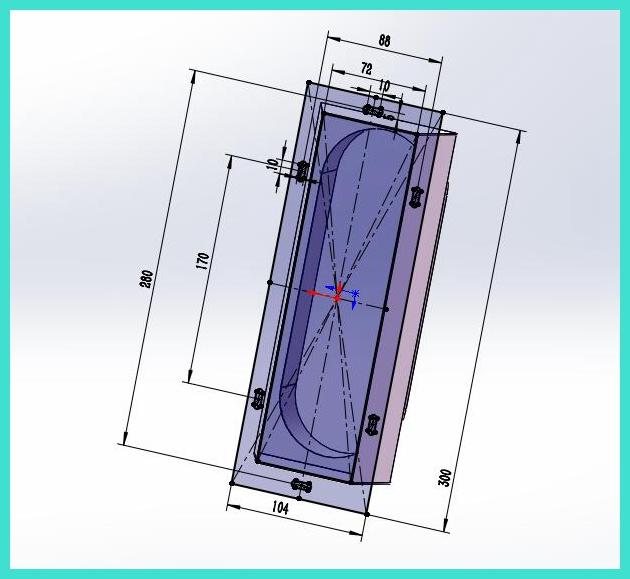

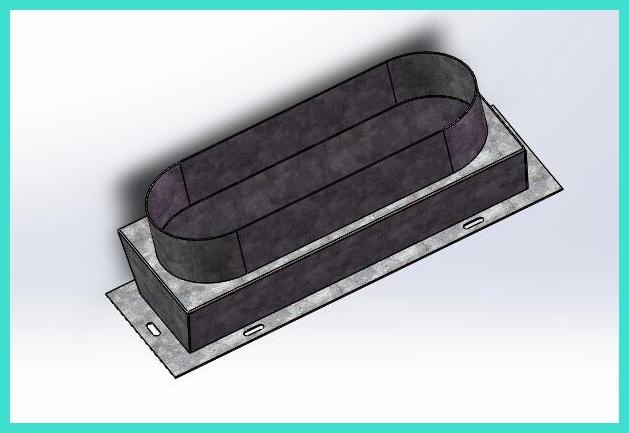

The following picture shows the sheet metal part of the air duct joint. This article mainly explains how to make and unfold this sheet metal part? The focus of this article is on the drawing of the middle edge flange!

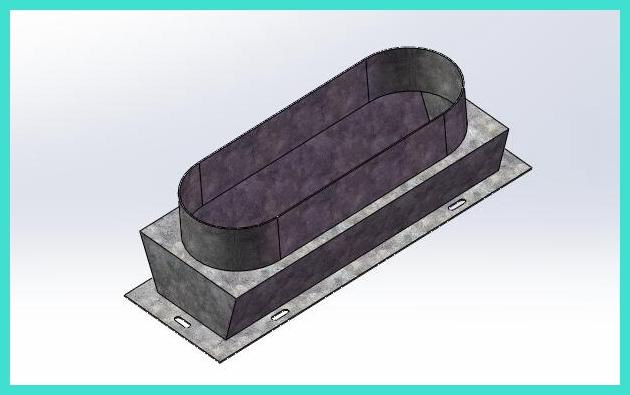

3D image:

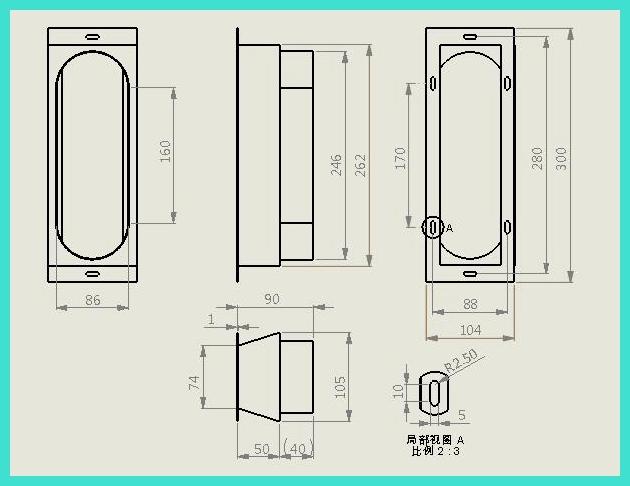

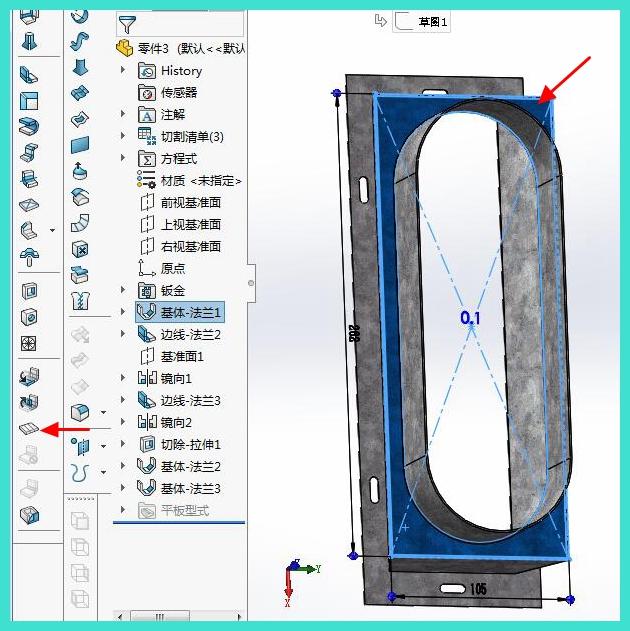

2D engineering drawing:

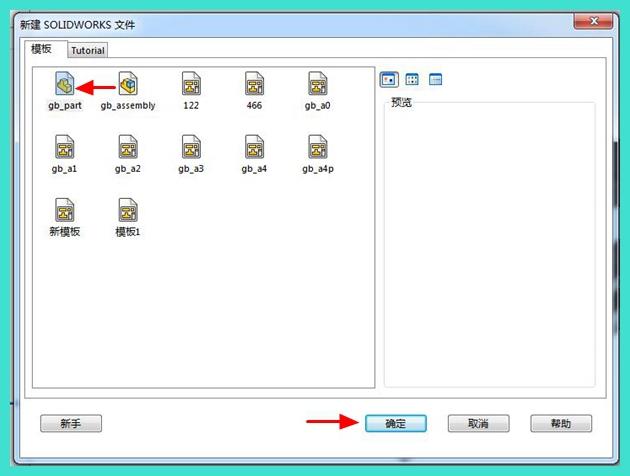

The drawing steps are as follows: 1. Open SolidWorks software, 【 New 】 - 【 Parts 】

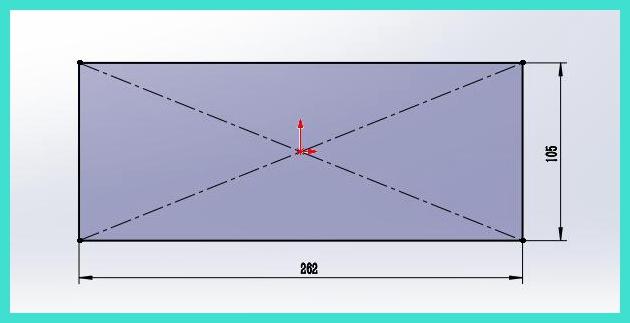

2. First, draw the base flange of the middle part 762 * 105. Click on [Sketch] to draw the sketch first

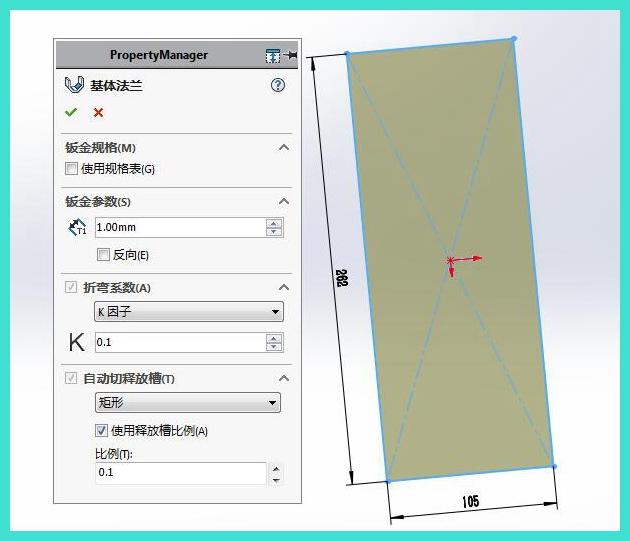

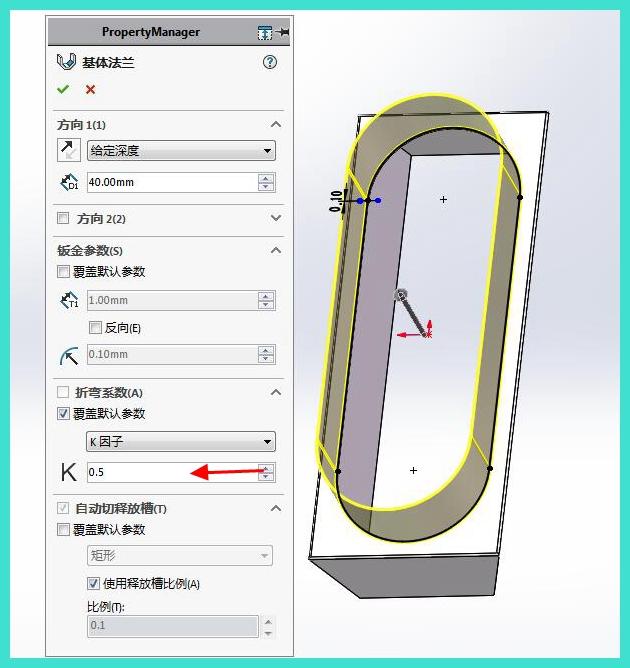

3. Click on "Base Flange" to set the plate thickness to 1mm, and first set the bending coefficient to a K factor of 0.1. 90 degree bending, large arc bending, set bending coefficient separately

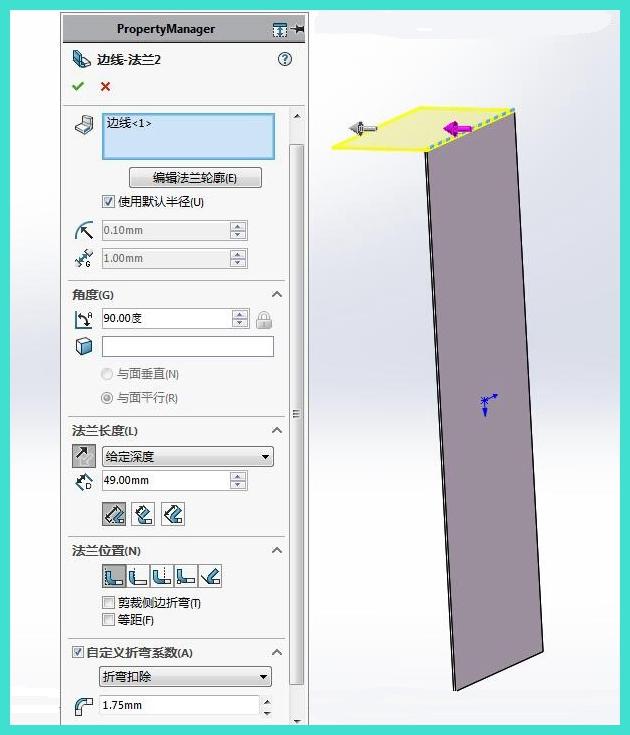

4. Click on [Edge Flanges] to set the angle to 90 degrees and depth to 49 degrees, and deduct 1.75 for bending

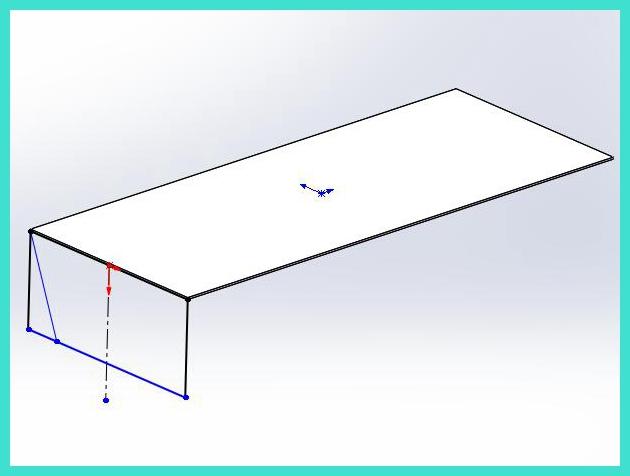

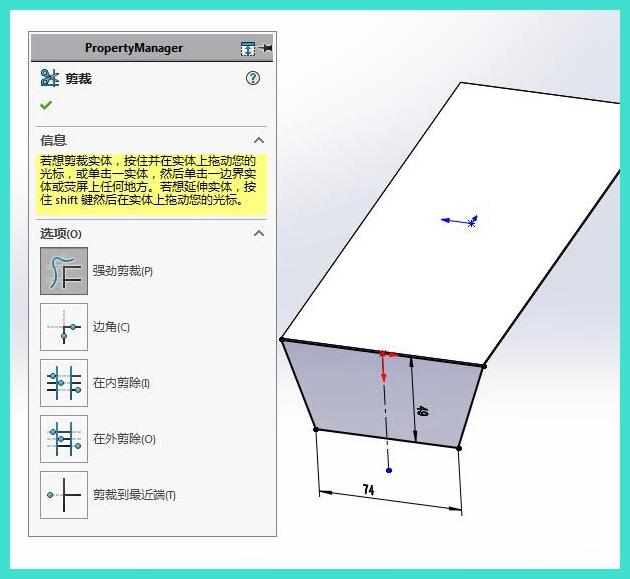

5. Edit the sketch of the edge flange

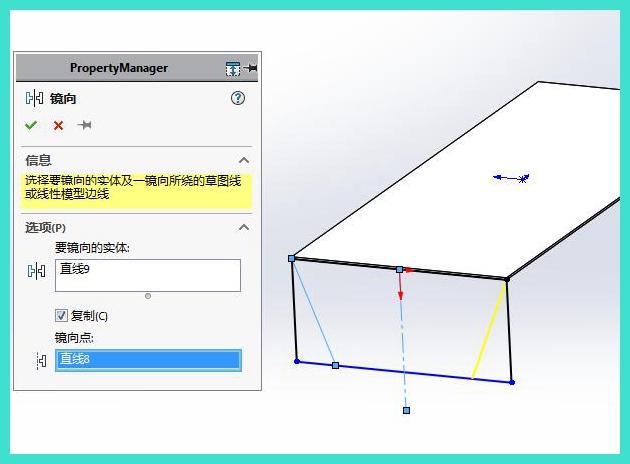

6. Click on [Mirror]

7. Click on the dimension annotation to generate the edge flange

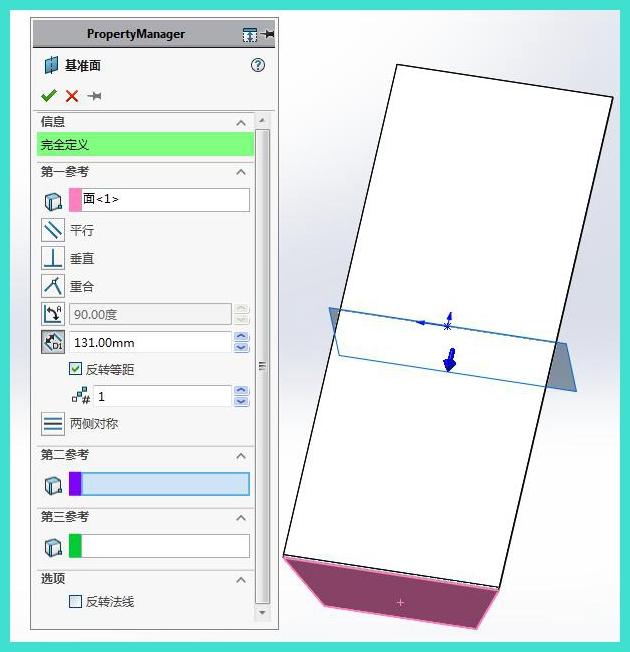

8. Click on [Reference Surface] to create a new reference surface with an offset distance of 131mm

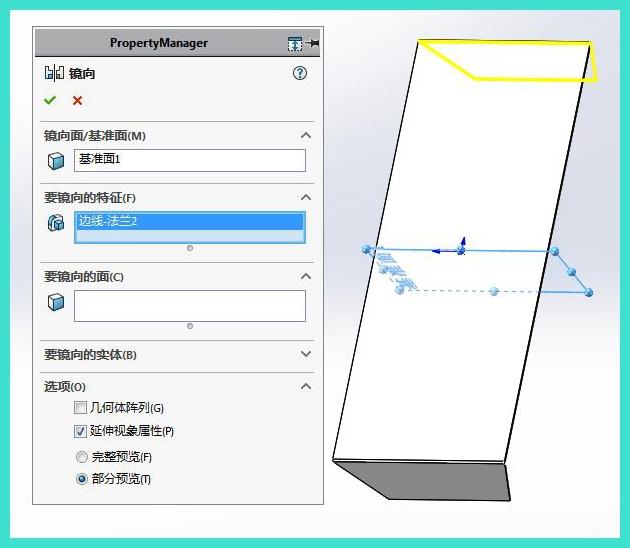

9. Click on "Mirror" to select the newly created reference plane 1 for the mirror reference plane, and select the edge flange for the feature to be mirrored

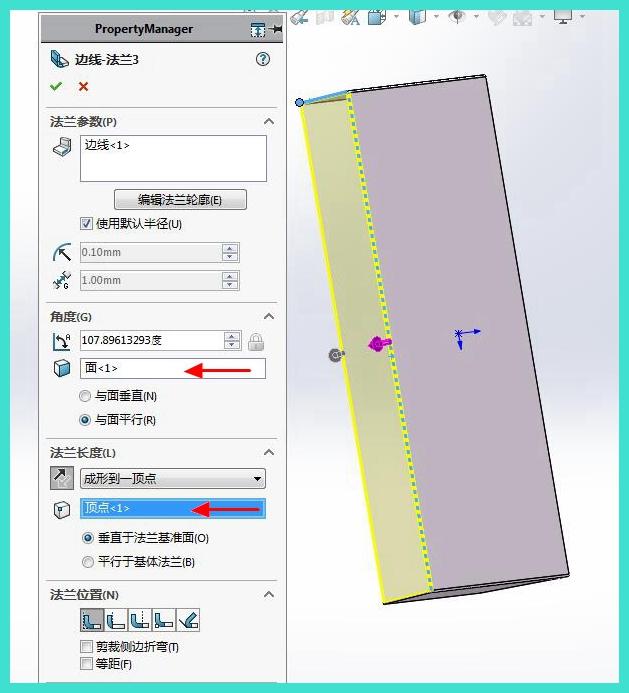

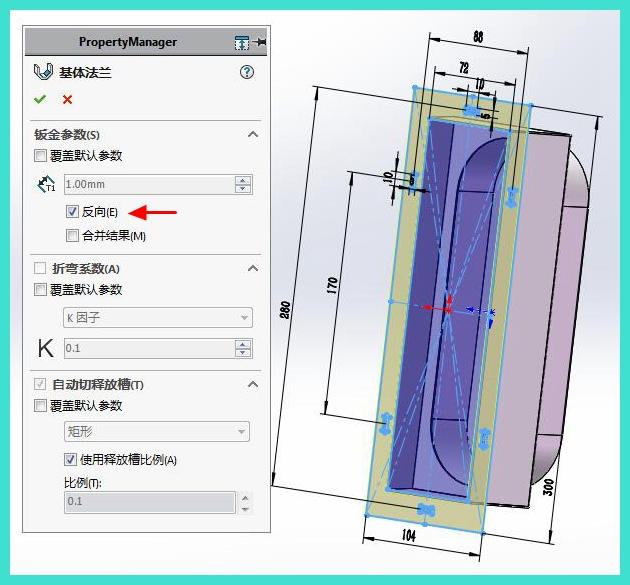

10. Click on the "Edge Flanges" button. The arrow in the figure below is the key setting point

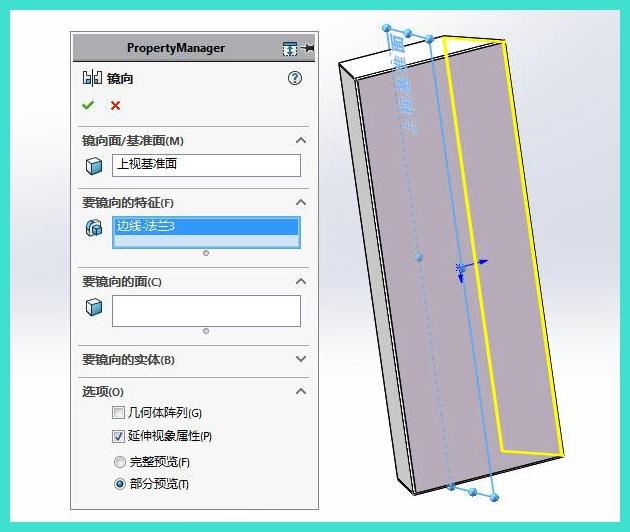

11. Click on the [Mirror] reference plane to select the upper reference plane, and select the edge flange of the previous step for the feature to be mirrored

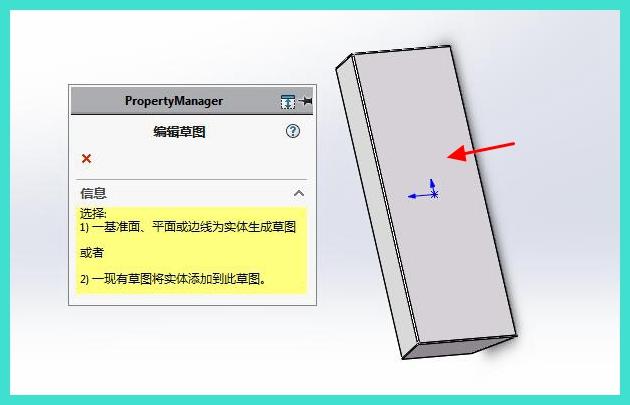

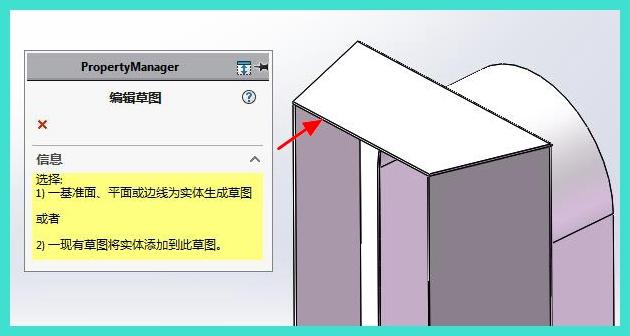

12. Click on [Sketch] to draw the sketch reference plane and select the plane indicated by the arrow

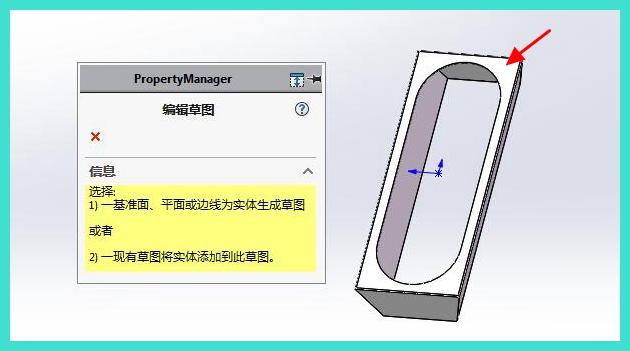

13. Draw a stretching and cutting sketch

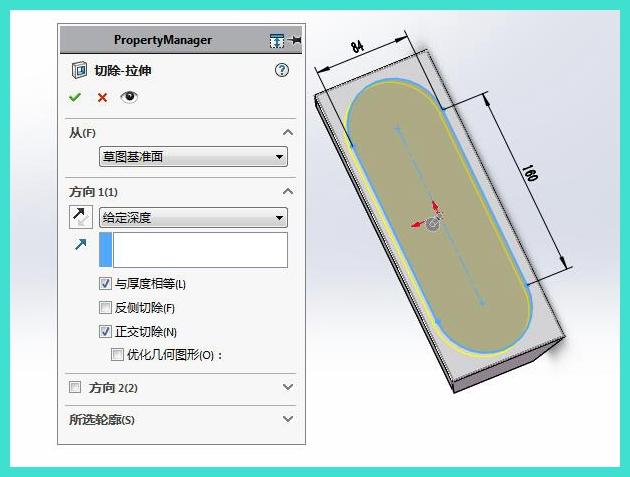

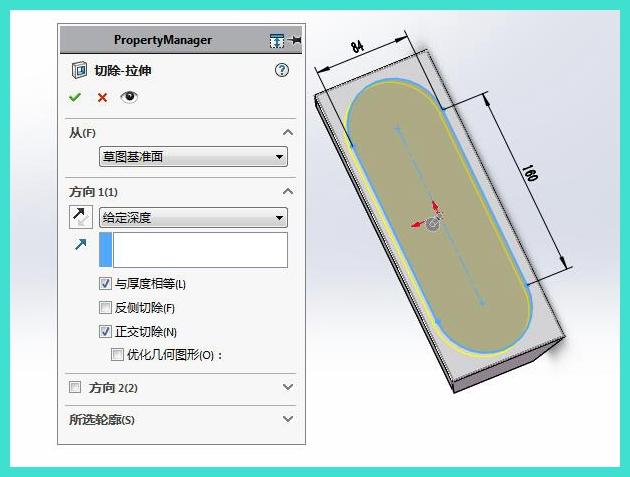

14. Click on stretch cutting and set parameters

15. Click on [Sketch] to draw the sketch reference plane and select the plane indicated by the arrow

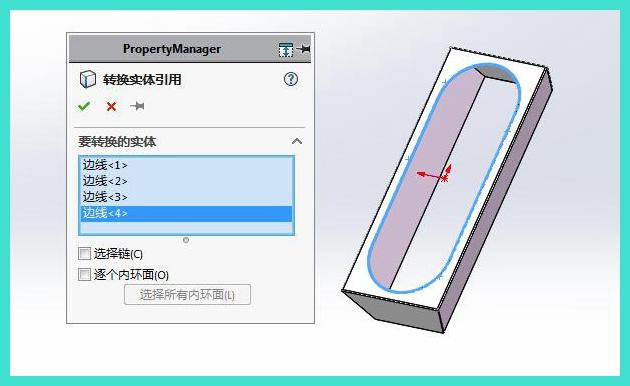

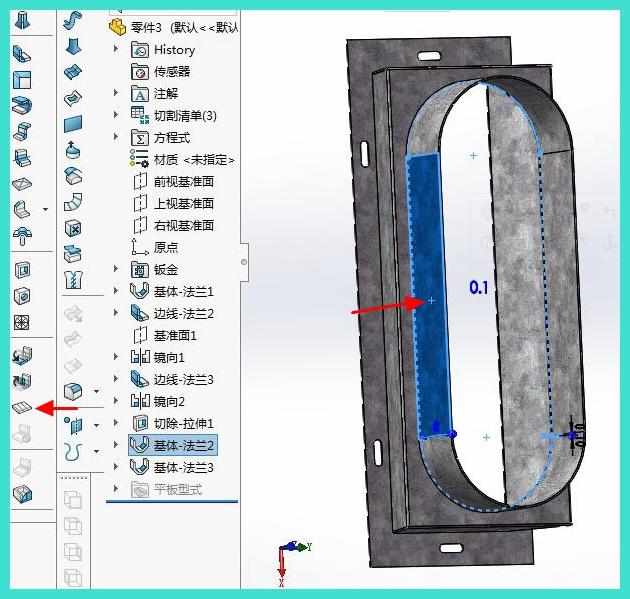

16. Draw a sketch and click on 'Entity Conversion Reference' to select the edge line for stretching and cutting

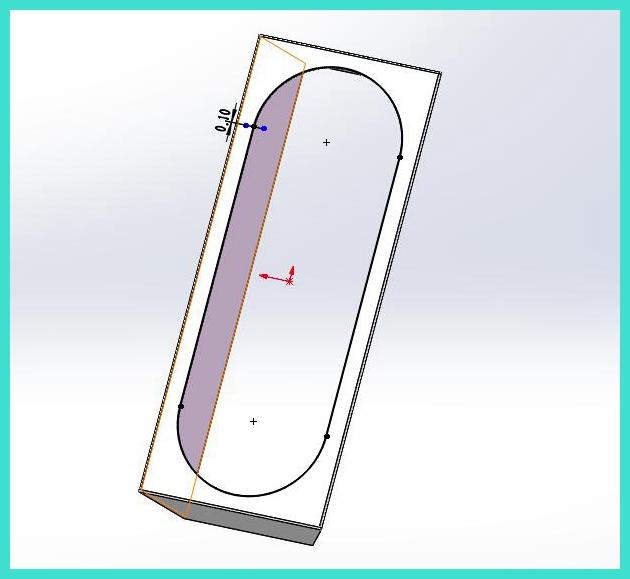

17. Make a gap in the referenced sketch

18. Click on [Base Flange] to set the depth. 40. Set the K factor to 0.5 to generate the base flange

19. Click on [Sketch] to draw the sketch reference plane and select the plane indicated by the arrow

20. Draw a sketch of the base plate

21. Click on [Base Flange] to generate the base plate

22. Rendering it

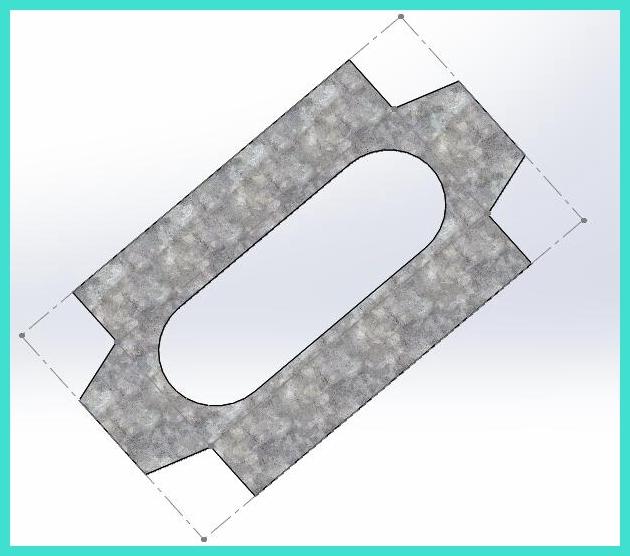

23. Select a face in the following image and click to expand it

24. Generate expansion

25. Click on the image below and click to expand

26. Generate expansion

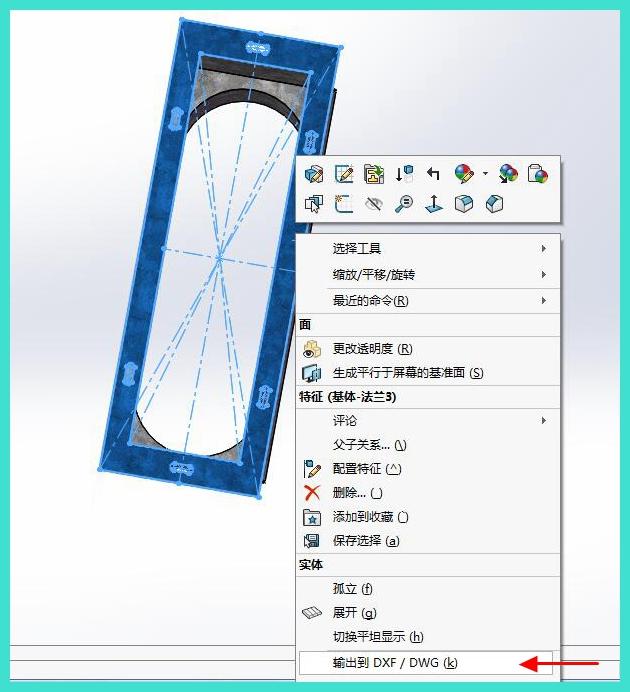

27. The bottom plate is not a bent part. Right click on the bottom panel and click the arrow below to directly generate CAD

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque