Nowadays, the manufacturing industry is mixed with good and bad, and there are many manufacturers of stamping parts. So how to choose a manufacturer that processes metal stamping parts? With the convenience of Internet information, you can first collect information on the computer or mobile phone, such as the size, technical strength, equipment, stamping quality, reputation, etc. of the manufacturer, and then select the appropriate manufacturer for inquiry after comparison.

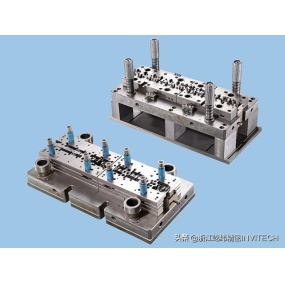

1. Look at the number of devices, more devices need to be new. The scale of a single device should be more than ten units, such as stamping machines, ranging from 30 tons to 300 tons. More stamping machines indicate that they can handle a larger number and variety of products, and can mass produce large quantities of products in a shorter period of time. There will also be more systematic team monitoring in the quality assurance management of customized hardware stamping parts, so it is necessary to choose suppliers with a certain number of equipment. There is also the degree of newness of the equipment. The accuracy of the parameters measured by new equipment is generally more reliable than that of old equipment, and the errors caused will be smaller. The newness of quality inspection equipment helps the quality control team adjust the quality of products on a large scale.

2. Check the number of quality control personnel and the frequency of product testing. Each process in the production of metal stamping parts requires specific quality control personnel to monitor in real-time and eliminate quality issues from the source of processing. Another thing to note is the frequency of detection, especially when using high-speed continuous stamping dies for production. You can also check for automated testing equipment that is more efficient, cost-effective, and provides more accurate results.

3. Judging from the technical strength, how much product manufacturing accuracy can be achieved? For example, Emma Technology Co., Ltd. can achieve 0.01mm, which is a very good point. Check if the technical team has rich experience, sufficient quantity, and can meet our technical requirements, etc. Take a look at the level of automation to see if it is possible to mass produce stable and consistent products in a short period of time.

Aima Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes businesses such as CNC Machining parts, metal stamping parts, and sheet metal processing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque