Stamping parts are a common type of hardware component widely used in various fields. Below, we will introduce some knowledge about stamped parts.

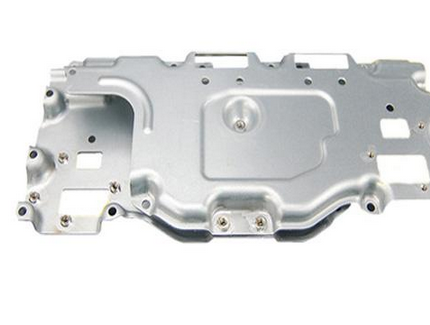

Firstly, stamping parts are formed by placing metal sheets in stamping molds and subjecting them to impact forces through stamping machinery equipment. The stamping process includes operations such as shearing, bending, stretching, and pressing. Through the design and processing of molds, metal sheets can be processed into various shapes and sizes of parts.

Stamping parts can be classified according to their purpose. Firstly, there are structural components, which are used to construct the main structure of the product, such as car bodies, mechanical equipment frames, etc. Secondly, there are connectors used to connect components such as bolts, nuts, pins, etc. The third is the guide element, which is used to guide and position the movement of parts, such as bearing seats, guide rails, etc. Finally, there are isolation components used to isolate and protect parts, such as gaskets, sealing rings, etc.

Stamping parts have many advantages. Firstly, stamping parts can be efficiently mass-produced, improving production efficiency. Secondly, the dimensional accuracy and shape complexity of stamped parts are high, which can meet various design requirements. In addition, stamped parts have good strength and rigidity, and can withstand large loads and pressures. In addition, the surface smoothness of stamped parts is high and can be used directly without further processing.

However, there are also some challenges in the manufacturing process of stamped parts. For example, the selection and performance of materials are crucial for the quality and performance of stamped parts. In addition, the design and manufacturing of molds need to consider the shape and size requirements of the parts, as well as the efficiency and cost of production. In addition, attention should be paid to safety and the technical level of operators during the stamping process.

In summary, stamping parts, as a common hardware component, have a wide range of applications in various fields. Through reasonable design and manufacturing processes, high-quality, precise sized, and diverse shaped stamped parts can be produced to meet the needs of different industries.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque