Aima Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes businesses such as CNC Machining parts, metal stamping parts, and sheet metal processing.

Metal stamping parts are a very common type of metal product in daily life, with a wide range of applications. Before carrying out stamping processing, stamping factories need to evaluate and plan the production situation to ensure that the stamped parts produced meet customer requirements. Next, let's learn how to process metal stamping parts reasonably.

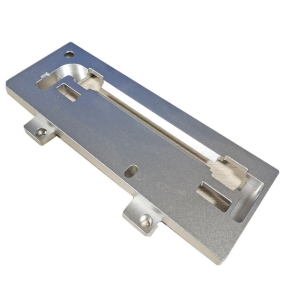

Metal stamping parts

(1) The stamping parts to be produced need to have satisfactory product application and technical characteristics, and be easy to assemble and maintain in a timely manner.

(2) The stamping parts to be produced need to be beneficial in maximizing the utilization of metal materials, reducing the types and specifications of materials, and minimizing material consumption. Under agreed conditions, use high-quality and cost-effective materials to ensure that the parts are cold stamped with minimal waste and no waste.

(3) The stamping parts to be produced need to have a simple appearance and effective structure, which is beneficial for simplifying the mold structure and simplifying the total number of process flows. That is, using at least a simple stamping process flow to complete the production and processing of all parts reduces the need for other methods of production and processing, and is beneficial for the actual operation of stamping. It is easy to allocate for mechanical automation and automation technology production to improve productivity.

(4) The stamping parts to be produced should have lower requirements for limit accuracy level and surface roughness level as much as possible while ensuring normal application conditions, which is beneficial for product interchangeability, reducing waste, and ensuring stable product quality.

(5) The stamping parts to be produced should be beneficial for using current machinery and equipment, processing technology configuration, and production processes to carry out production and processing, and for increasing the service life of stamping molds.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque