Sheet metal chassis is one of the commonly used types of enclosures in modern electronic products, which has the advantages of high structural strength, easy processing, and beautiful appearance. Today, Gu Er Mei will take you to understand the processing of sheet metal shells, including cutting, stamping, bending, welding, spraying and other steps.

one ️⃣ Material cutting

The main raw material for sheet metal chassis is metal sheet, which needs to be cut according to the requirements of the design drawings. When cutting, attention should be paid to the accuracy of size and shape, while considering the utilization rate of materials and the feasibility of subsequent processing.

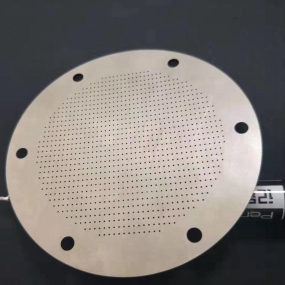

two ️⃣ stamping

Stamping is one of the most important steps in sheet metal chassis processing, which uses molds and stamping tools to process metal sheets into the desired shape and structure. When stamping, it is necessary to consider the rationality of product design and the level of production efficiency.

three ️⃣ Bending

Bending is the process of bending metal sheets according to design requirements. When bending, attention should be paid to the stretching and deformation of the material, while also ensuring the processing accuracy and product stability.

Customized sheet metal shell

four ️⃣ welding

Welding is one of the methods of connecting metal sheets or parts together. In sheet metal chassis processing, high-precision welding methods such as laser welding or resistance spot welding are usually used for welding to ensure the stability and sealing of the product.

five ️⃣ spray

Spraying is the process of uniformly spraying paint or powder coating onto the surface of sheet metal chassis. When spraying, attention should be paid to the thickness and uniformity of the coating, while also protecting the appearance and performance of the product.

Overall, sheet metal chassis processing is a technically demanding job that requires processing personnel to have professional skills and rich experience. At the same time, the processing of sheet metal chassis also requires the introduction of advanced technology and equipment to improve production efficiency and product quality.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque