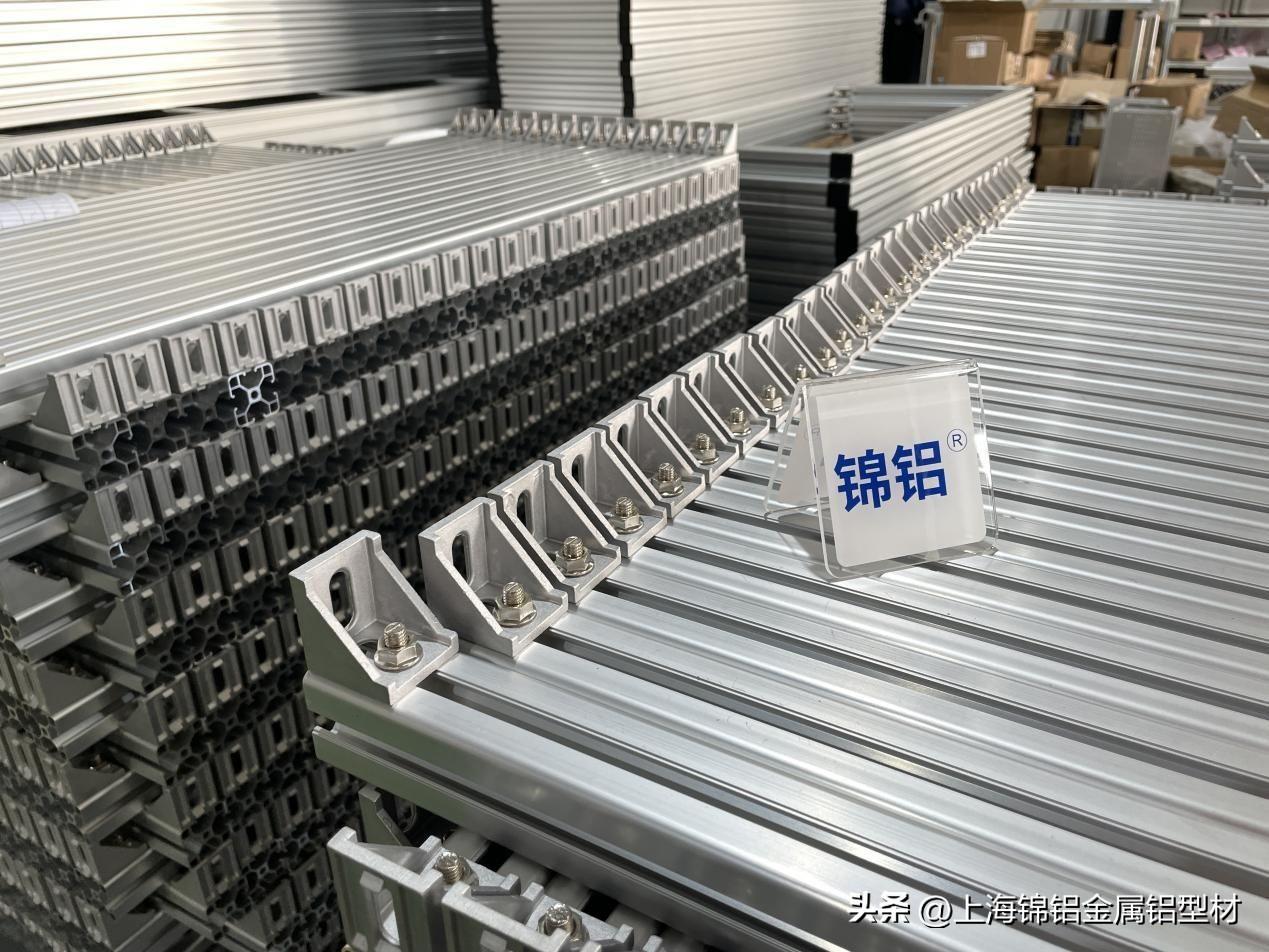

What is the cost of processing industrial aluminum profiles? Aluminum profiles are widely used metal raw materials in various industries in modern times. It refers to aluminum materials with different cross-sectional shapes obtained by melting and extruding aluminum rods. So, what are the components of the aluminum profile processing fee? How is the processing fee for aluminum profiles calculated. Usually, the exact cost of aluminum processing varies by factory.

This quotation cannot be used as a reference for purchasing aluminum materials, as manufacturers may vary in the following aspects:

1. Uneven quality: Many manufacturers with low processing costs usually do not pay much attention to product quality and do not strictly control size accuracy and appearance shape, resulting in a price difference of about 500 yuan.

2. Different raw materials: There are many types of scrap aluminum, some manufacturers mix aluminum ingots with scrap aluminum, while others directly use raw aluminum ingots as our factory's starting and ending materials. This effect will be reflected in a processing cost difference of about 1500 yuan.

There are significant differences in the processing technology of aluminum profiles: extrusion technology and extrusion equipment. The process and market of domestic recycled aluminum are different, and there are also significant differences in mold manufacturing technology, resulting in a price difference of about 500 yuan/month.

4. Packaging costs, many manufacturers use packaging materials as aluminum for shipping. Therefore, there is no doubt that the lower the processing cost of aluminum profiles, the lower the product quality will be.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque