To understand the processing methods of industrial aluminum profiles, the first thing to understand is whether to change the processing method of aluminum profile structure or the processing method of industrial aluminum profile surface processing technology. Generally speaking, CNC machine tools can easily change the mechanism of aluminum profiles, whether it is milling, drilling, tapping, stamping, bending and other processes can achieve deep processing.

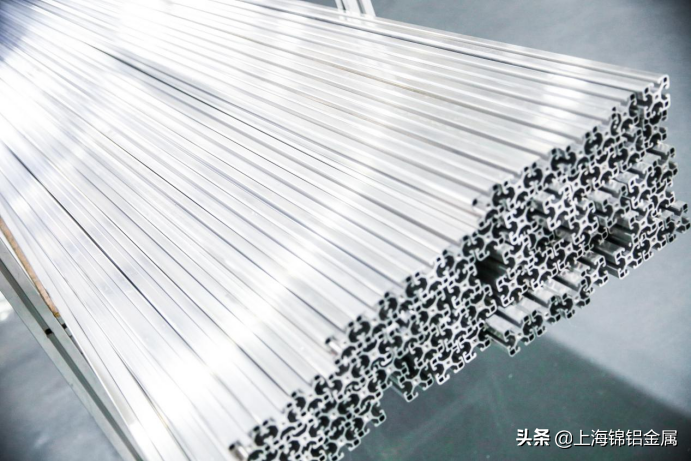

The surface treatment and processing methods for industrial aluminum profiles of Jinlu are as follows:

Firstly, the sandblasting process: the process of cleaning and roughening metal surfaces using the impact of high-speed sand flow. This method can achieve a certain degree of cleanliness and different roughness on the surface of the workpiece, improve the mechanical properties of the workpiece surface, and thus enhance the fatigue resistance of the workpiece.

Next is polishing: a processing method that uses mechanical, chemical, or electrochemical methods to reduce the surface roughness of automotive aluminum parts, in order to obtain a bright and smooth surface. The polishing process is mainly divided into mechanical polishing, chemical polishing, and electrolytic polishing.

Next is wire drawing: Metal wire drawing is the manufacturing process of repeatedly scraping aluminum plates into lines with sandpaper. Wire drawing can be divided into straight line drawing, wheel line drawing, spiral line drawing, and thread drawing.

Finally, anodizing treatment: the surface of industrial aluminum profiles is treated with silver white oxidation, which is elegant, beautiful, and corrosion-resistant.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque