Industrial aluminum profiles are gradually entering the public's field of vision. Many times, industrial aluminum profiles are used as special processing parts or beams, which require deep processing. CNC Machining is one of the ways of deep processing, which can save labor costs and achieve high precision during processing. So what are the processes involved in CNC machining? Let's take a look!

1. Aluminum profile cutting:

Aluminum profile cutting is the simplest and most common processing method in CNC machining, which involves cutting into different lengths according to the customer's needs.

2. CNC drilling:

Industrial aluminum profiles do not require welding and are generally connected through accessories. Different aluminum profiles have different connection methods and will also be perforated to varying degrees, including but not limited to through holes and stepped holes. Drilling process is a common and technically advanced process in CNC machining of aluminum profiles.

3. Tapping of aluminum profiles:

Aluminum profile tapping is commonly referred to as threading. Aluminum profiles are processed by threading the tapping holes at the end of the aluminum profile according to the technical requirements of the design drawings, which is used for later frame fastening connections.

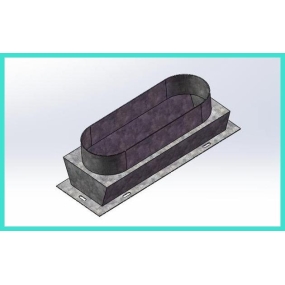

4. Milling machine CNC milling:

The conventional assembly of aluminum profiles does not require CNC milling for processing, but in special cases where non-standard parts are used in conjunction with profiles, CNC machining may be required for aluminum profiles.

The above are all CNC machining processes for aluminum profiles. Do you understand?

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque