Numerical control machine tools provide automatic machining methods for high-precision and high-efficiency product production, especially for the production of complex surface parts

1、 Basic concepts

1. Digital control

An automated method for programmable control of a work process (such as machining, measurement, assembly, etc.) using numbers, characters, or other symbols

2. Numerical Control Technology

The technology of using numerical quantities and characters to issue commands and achieve automatic control has become the fundamental technology for manufacturing to achieve automation, flexibility, and integrated production

3. Numerical Control System

Control system using digital control technology

4. Computer Numerical Control System

Numerical Control System with Computer as the Core

5. CNC machine tools

A pre programmed program according to processing requirements, which sends digital information instructions from the control system to process the workpiece

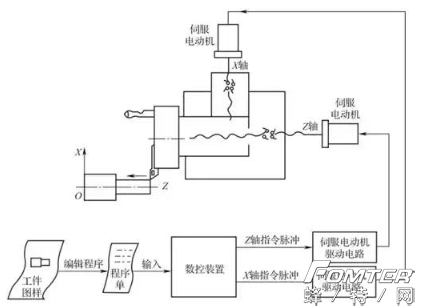

2、 The working process of CNC machine tools

1. Develop a program

2. Input to CNC device

3. Processing and calculation

4. Issue instructions

5. Drive orderly actions and operations

6. Realize the relative motion between the cutting tool and the workpiece

3、 Characteristics of CNC machine tools

1. Strong adaptability and good flexibility in processing parts

2. High processing accuracy and stable product quality

3. Strong comprehensive functions and high production efficiency

4. High degree of automation reduces labor intensity for workers

5. Reduced production costs and good economic benefits

6. Digital production and improved management level

4、 Types of commonly used CNC machine tools

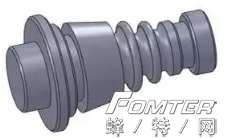

1. CNC lathe

A CNC machine tool used for completing turning operations. Its main motion is the rotation of the workpiece relative to the tool, and the cutting energy is provided by the workpiece rather than the tool

2. Turning center

Equipped with a power driven tool device and the ability to position the workpiece spindle around its axis. Equipped with a knife magazine that can automatically change knives. Capable of completing machining of end faces, radial and eccentric turning, milling, drilling, and boring

3. CNC milling machine

Numerical control machine tools that use milling as the processing method usually have milling cutter rotation as the main motion, and the movement of the workpiece or (and) milling cutter as the feed motion

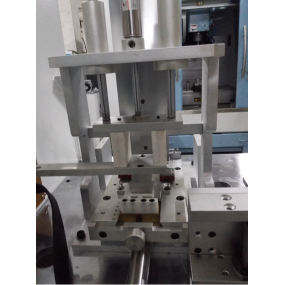

4. Machining center

Equipped with a tool magazine and automatic tool exchange device. The spindle is usually a horizontal or vertical structure and has two or more machining methods

5. CNC grinding machine

Use grinding tools to grind the surface of the workpiece. Most CNC grinders use high-speed rotating grinding wheels for grinding processing, while a few use other grinding tools such as oilstone, sand belt, and free abrasives for processing

6. CNC drilling machine

Mainly use drill bits to machine holes on workpieces. The rotation of the drill bit is the main motion, and the axial movement of the drill bit is the feed motion

7. CNC EDM forming machine tool

Use electric discharge machining method to process cavities, bodies, holes, and surfaces. Its working principle is to use two electrodes of different polarities to generate discharge phenomena in insulating liquid, removing materials

8. CNC wire cutting machine tool

An electric discharge machining machine that uses metal wire as a tool electrode to cut and process workpieces. Its working principle is the same as that of CNC electric discharge forming machine tools

5、 Application of commonly used CNC machine tools

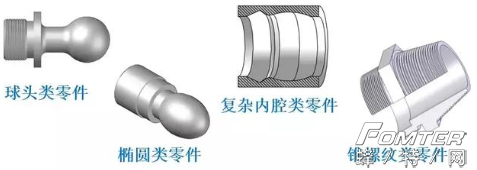

1. Application of CNC lathe

Processing rotary parts with particularly complex contour shapes or difficult to control dimensions, rotary parts with high precision requirements, and rotary parts with special threads

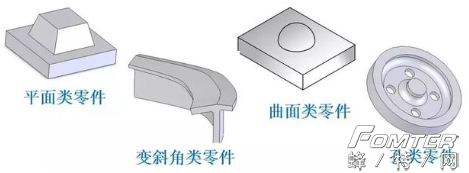

2. Application of CNC milling machine

Processing two-dimensional or three-dimensional contour parts, such as planar contour, inclined contour, and curved contour; It is also possible to process hole type parts, such as drilling, expanding, countersunking, reaming, boring, and threading

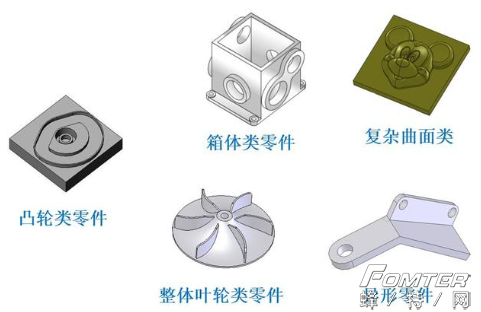

3. Application of machining centers

Suitable for processing complex, multi process, high-precision parts that require multiple cutting tools and can only be processed after multiple clamping and adjustments

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque