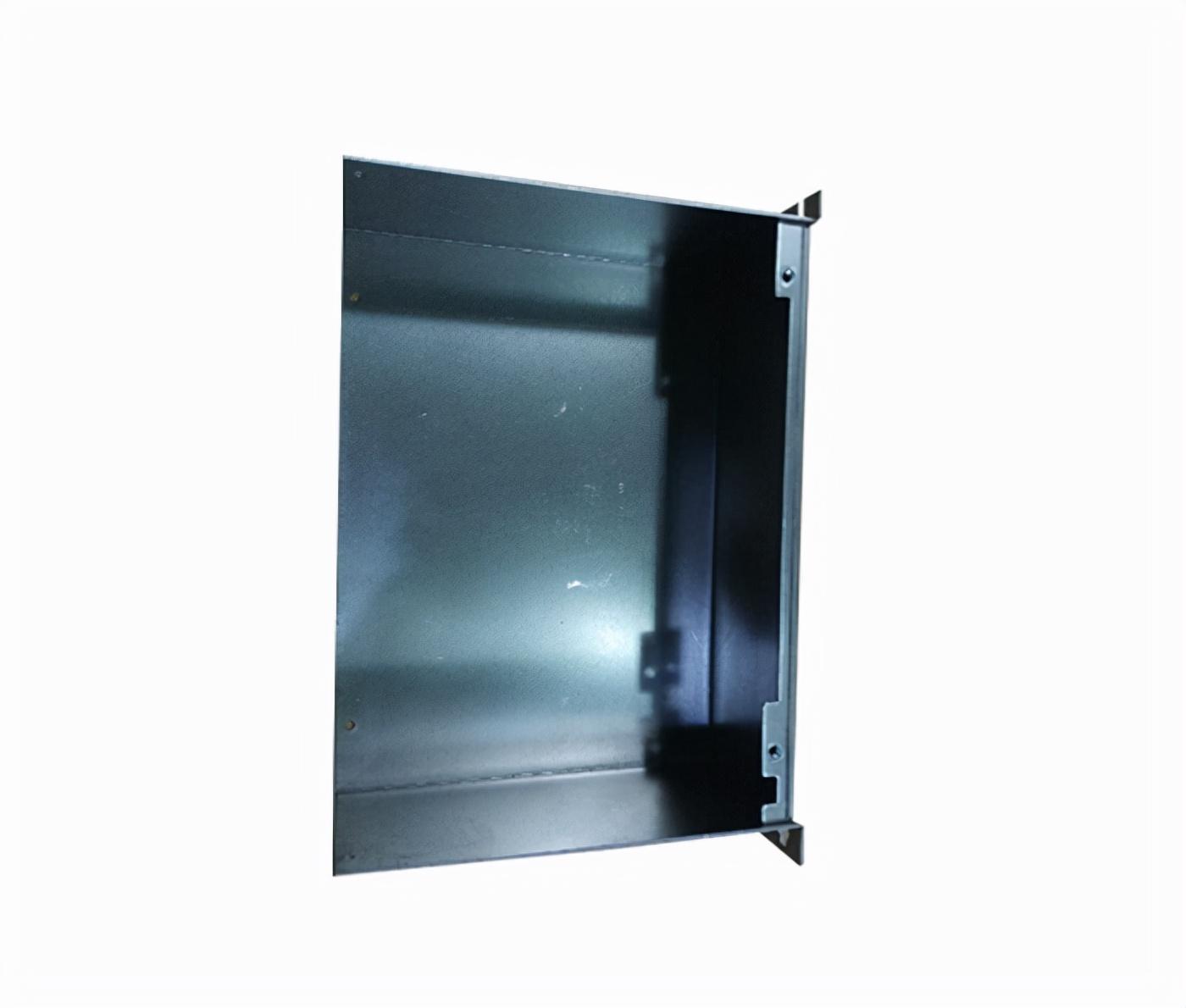

With the increasing demand for Sheet Metal Processing parts in the market, sheet metal processing companies are constantly emerging like mushrooms after rain. So which sheet metal processing company is good has become a topic of concern for many users. How to choose a good sheet metal processing company? Below, the editor from Aima Technology Co., Ltd. will teach you:

1. Judging by Strength:

A good sheet metal processing company generally has strong economic and technical strength, because economic strength is the basic guarantee for its product processing and services, and technical strength is the guarantee for product quality and performance. The overall environment of a company reflects its operational status, and the professional ethics of its employees reflect its standardization. Therefore, only strong companies can produce sheet metal parts that meet customer needs.

2. Looking at processing technology and assembly lines:

When deciding to start a cooperation with a sheet metal processing company, it is important to have sufficient understanding of the processing technology and assembly line workflow of the factory. If a manufacturer is relatively backward in technology, it will not be able to produce high-quality sheet metal products. Therefore, it is recommended that everyone visit the manufacturer for inspection.

3. View customer case studies:

If the manufacturer has rich sheet metal processing cases, they will inevitably accumulate rich experience, which is much more reliable compared to those without customer cases.

4. Check after-sales service:

No matter what kind of enterprise it is, it should have professional after-sales service. If a manufacturer's after-sales service is not good, do not choose, they will not provide us with professional service, nor can they solve our problems, which will affect the entire user experience.

If all the above points are satisfactory after investigation, it indicates that the sheet metal processing company is relatively good. Otherwise, caution should be exercised when choosing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque