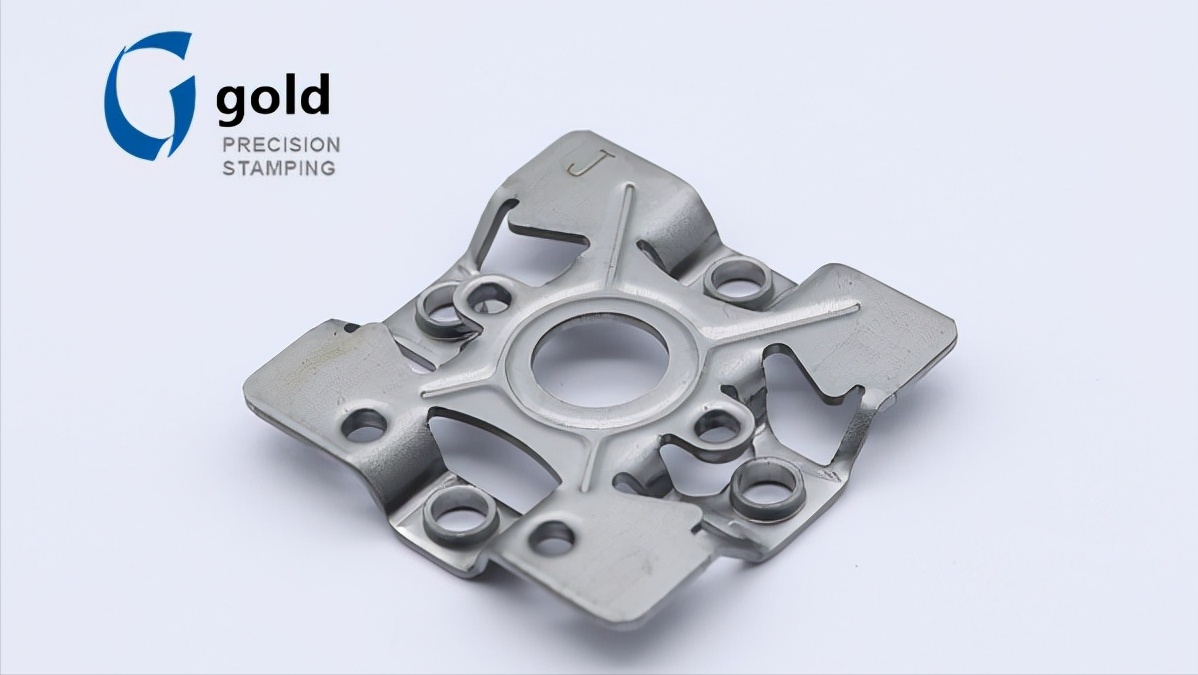

According to the shape of the component or product, Metal Stamping involves various different processes, each of which is different. These processes are used to achieve complex and meticulous design of parts and products in industries such as aerospace, consumer products, automotive, aviation, electronics, food and beverage, etc. It is usually not possible to manufacture a component using a single metal stamping method, as each process involves creating a specific design.

Many stamping techniques involve processes such as extrusion, stretching, and rib pressing. Each technology involves a mixture of various processes to achieve the required components. All of these methods are performed at room temperature, typically involving minimal or zero heat. Hardware stamping is a typical cold forming manufacturing process that involves the use of several tools and equipment, such as stamping machines (punch presses), molds, etc., to form complex shapes and appearances.

In view of this, we will discuss some of the most popular hardware stamping processes used by manufacturers.

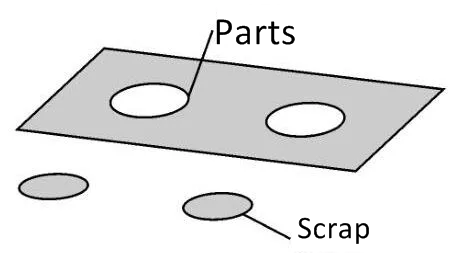

Punching method is a common metal stamping process. A metal plate is fixed in one place, or more precisely, on a workbench. Using different tools and machines, create a hole on a metal plate and create a series of different hollow areas on the metal plate. Punching is a bit different because after punching on a metal plate, the perforated part is removed and no longer used.

To ensure that the metal plate is not deformed, punching must be a continuous process. The area around the punching must be precisely designed. The machine used in this metal stamping process is made of high carbon steel and must be thoroughly maintained so that there are no passivation or areas of passivation, which may cause deformation of the metal plate shape.

There is not much difference between the cutting method and punching - however, a big difference is that perforated boards will not be thrown away. The punched sheet is the final component. Many metal stamping companies usually carry out stamping before doing other things on the project. After the material cutting is completed, the manufacturer will proceed with other hardware stamping stages such as extrusion and bending.

Material cutting essentially involves manufacturing sheet metal - usually on small or medium-sized metal sheets cut from large pieces. When it comes to mass production, this is a particularly advantageous process as it is easy and leads to high-quality and precision based cutting.

However, in some cases, metal plates may contain unwanted edges or burrs. This is a common question; However, sharp edges and burrs will eventually be removed through several processes, such as thermal deburring, manual deburring, and/or vibration methods.

When it comes to metal stamping, some manufacturers also use the so-called stretching process. This method basically involves firmly fixing the two ends of the metal plate (opposite ends). The next step is to place the metal plate on a mold with a cross-sectional shape. Through a powerful stamping process, the mold produces a punch that pushes the sheet metal onto the machine. This helps to develop the cross-sectional shape of the machine, fully deforming the metal plate to meet the requirements.

The stretching method can also be divided into two other processes, called deep stretching and shallow stretching. These are similar processes to achieve the required depth on a metal plate. For example, during shallow stretching, the radius of the main metal plate will always correspond to the depth of stretching, which means it will be equal.

On the other hand, deep stretching is basically cup-shaped cutting on metal plates to form different products. During the deep drawing process, the total radius of the metal plate is much smaller compared to the depth to be carried out.

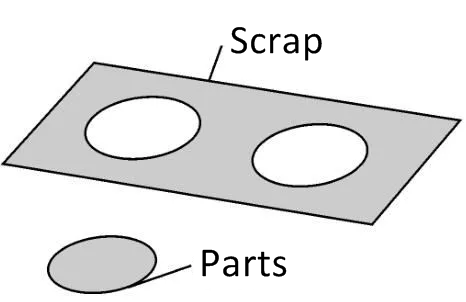

The extrusion method in metal stamping is a typical process used by manufacturers to manufacture products and components with extruded shapes. The squeezing method involves a '; Closed mold; Manufacturing technology. In this case, the metal plate is used as a whole or squeezed into parts. This process involves two independent molds, whose positions gradually approach each other at the two ends of the metal plate, forming a coin shape.

One of the biggest benefits of the extrusion method is that it is very effective in manufacturing various metal parts and products with different quantity tolerances. It is also a relatively direct technology that can quickly and reliably produce deformations (usually permanent) on products. This essentially makes the component or product highly resistant to deep physical wear and strong impacts.

The tongue cutting technique is completely different from the cutting and punching methods. How to put it? Well, tongue cutting involves a unique metal stamping process that does not require removing any metal parts from the sheet metal. The punching and mold process is set to create a deep seam on the metal surface. The purpose of doing so is to avoid generating any metal waste, such as metal plugs that need to be disposed of or removed in the post-processing stage.

One of the main reasons why manufacturers use tongue cutting is that this process helps create various unique and customized designs and shapes using different types of metals. For example, it is commonly used to create components and parts that need to be used for applications such as openings, vents, labels, etc.

The reinforcement method for metal plates is another unique technique used to design raised surfaces in specific areas of the metal plate. Reinforcing bars can be created using two different methods - through mold sets or machines. The reinforcement method is mainly used to create parts and components for various applications, depending on the complexity and form of the required design. For example, some of the best examples of using corrugated components include metal coverings, engine hoods, engine casings, door frames, checkerboard steel plates, and so on.

The reinforcement technique can be used on different metal surfaces, however, the most popular metal type in this process is aluminum. This is mainly because this metal is very easy to process. In addition, this material is durable and lightweight, both of which contribute to making the reinforcement process more efficient and effective.

Important factors to be aware of during the metal stamping process

When it comes to metal manufacturing, metal stamping technology is very useful. Since that's the case, each process is mentioned based on the complexity of the technology. For example, fast and direct processes such as material dropping or punching are often referred to as the initial level of any project. These processes are then accompanied by other processes to form the finished product.

On the other hand, complex stamping procedures such as deep drawing, tongue cutting, extrusion, and/or rib pressing are mainly used to create complex designs that do not require processing throughout their entire production cycle.

In summary, metal stamping is an extremely important and future oriented process that is crucial for many industries. This process is used to manufacture daily consumer products, as well as larger components and parts for manufacturing vehicles and other things.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque