Sheet Metal Processing is divided into production cutting, stamping, bending, forming, welding, polishing, spraying, printing, assembly and other processes. Today, we will introduce in detail the process knowledge of stamping.

Stamping processing technology is a fiber laser cutting production and processing method for metal materials, which is important for metal materials. Based on pressure equipment such as stamping machines, the material is forced to deform or separate to obtain the actual required product parts, collectively referred to as stamping parts.

There are various situations in the stamping process of molds, and here I will summarize the most extensive stamping process for everyone.

1. Punching and cutting

The general term for a stamping process that extracts materials. It includes: cutting, punching, punching, grooving, slicing, chiseling, edge pressing, cutting, etc.

2. Exterior Design

The main purpose is to cut off the excess material and ensure that the stamping process meets the specifications and model requirements.

3. Cut the tongue

Make a cut in a certain part of the material, but not all of it is cut. It is common to cut only three sides of a rectangle while keeping one side still, mainly for setting the step distance.

4. Expand the mouth

This process is not extensive, and it is common to see the process of expanding the end or one end of a tubular part outward into a trumpet shape

5. Shrinking mouth

Contrary to expansion, it is a stamping process in which the end or a certain point of a tubular part must be reduced inward

6. Punching hole

In order to better obtain the hollow part of the part, the complete material will be separated by a punch and a cutting edge in the middle to obtain the corresponding hole size

7. High precision stamping

When stamping parts require a section quality of fully bright band, it can be called "precision punching" (note: ordinary punching sections are divided into four parts: corner collapse zone, bright band, fracture zone, and burr zone)

8. Full Bright Punching

Unlike high-precision stamping, full gloss stamping aims to achieve maximum results in a single step of stamping

9. Deep hole punching

When the diameter of the product is smaller than the thickness of the material, it can be controlled as deep hole punching, and the difficulty of punching is manifested in the fact that the needle is very easy to break

10. Strike convex hull

The process of creating a protrusion on a flat material with relative application requirements

11. Forming

Many friends master forming as sheet metal bending, but it is not done carefully and conscientiously. Because sheet metal bending is a type of forming, it refers to the general term for all fluid material processes during forming

12. Sheet metal bending of sheet metal parts

A basic process of brittle fracture of flat materials based on convex and concave mold inserts to obtain relative angles and patterns

13. Compression bar

This is generally used for sheet metal bending and forming inserts with inclined angles. It is mainly based on creating convex pits in the material at the bending position of the sheet metal to reduce material resilience and ensure angle stability

14. Embossed pattern

A process of designing unique patterns on the surface of materials by pressing them in with inlaid needles, widely including: lettering, small black dots, etc

15. Roll round

A type of molding manufacturing process, which is based on the process of designing and stacking product shapes into a circular shape

16. Flip hole

The process of outward curving the threads of stamped parts to obtain a certain height of side edges

17. Adjust straight

Mainly for situations where high flatness requirements are needed for products, when flatness errors occur in stamped parts due to stress fields, straightening processes must be used for adjustment

18. Integer type

When the angle and shape of the product are not the basic specifications and models after molding, it is necessary to fully consider adding another process to adjust them to ensure angle stability. This type of process is called "integer molding"

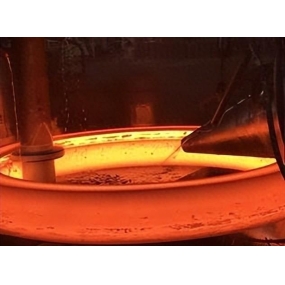

19. Stretching

The entire process of obtaining hollow parts from flat materials according to the method is generally referred to as the stretching process, which is mainly carried out based on convex and concave molds

20. Continuously stretching

Generally refers to a stretching production process in which materials at the same position are stretched multiple times in a material strip based on one or four molds

21. Loosening and deep drawing

Both continuous and deep stretching belong to the loose stretching stretching series, which means that the wall thickness of the stretched parts will be less than the thickness of the material itself

22. Stretching

Its basic concept is similar to convex hull, both of which involve making the material convex. However, deep drawing generally refers to small car parts, which belong to a relatively complex molding product series, and their deep drawing structure is also relatively complex

23. Construction project model

A set of molds that only carry out one stamping process in one stamping process are collectively referred to as molds

24. Composite mold

A set of molds that can carry out two or more different stamping processes in one stamping process are collectively referred to as molds

25. Stamping die shell

A set of molds is fed by a material belt, which arranges two or more processes in sequence and feeds them in sequence with the stamping process to finally achieve qualified products. It is a general term for the types of molds

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque