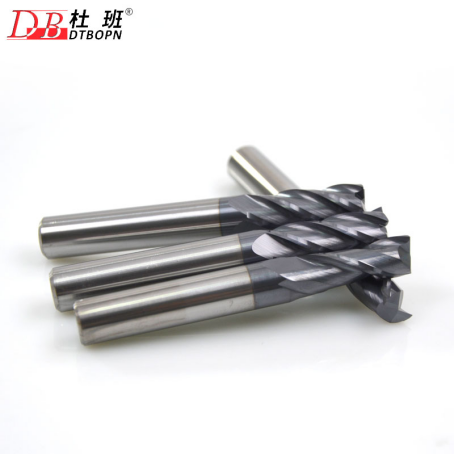

Hardware tools, as the name suggests, refer to a general term for various metal devices made from metals such as iron, steel, and aluminum through physical processing such as forging, rolling, and cutting. They play an indispensable and important role in people's daily lives and work. Let us tell you about the important roles played by Du Ban DTBOPN Mingzhou Electronics here~

Precision hardware tools can contribute greatly to machining, and their advantages are closely related to many manufacturing industries. What are the specific advantages? Let's keep looking down!

1. Precision metal axis CNC Machining has high precision and stable machining quality. And our DuPont DTBOPN Mingzhou Electronics has ultra-high processing accuracy and more stable processing quality. Currently, the fields we process cover precision components in the automotive, automation equipment and other fields. The accuracy requirements of some parts are strictly controlled within 0.005-0.01mm, which has been favored by many enterprises!

2. It can perform multi coordinate linkage and process parts with complex shapes.

3. When precision hardware CNC machining parts change, generally only the CNC program needs to be changed, which can save production preparation time. For example, our Du Ban DTBOPN Mingzhou Electronics has precision technology and dedicated CNC program storage, which can save pre production preparation time when replacing machined parts!

4. The machine tool itself has high precision and rigidity, and can choose favorable processing quantities. Its productivity is high, generally 3 to 5 times that of ordinary machine tools~

5. The high degree of automation of machine tools can reduce labor intensity.

Generally speaking, the use of short cutting tools in CNC precision machining is the main characteristic of precision hardware parts. Short tools can significantly reduce tool deviation, thereby achieving good surface quality, avoiding rework, reducing the use of welding rods, and shortening EDM processing time. When considering five axis machining, it is necessary to consider that the goal of using five axis machining molds is to complete the entire workpiece machining with the shortest possible cutting tools, including reducing programming, clamping, and machining time while achieving more perfect surface quality.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque