Numerical control milling machines are very common in machining production. Due to the development of numerical control equipment, the quality and efficiency of production have been improved to a certain extent, and they are better used in production. Therefore, more and more mechanical processing enterprises attach importance to numerical milling machining and widely use it in the field of metal processing. So what are the classifications of familiar processing? What is the classification quotation table for numerical milling processing?

1. CNC milling machine

(1) Simplified CNC milling machine: A CNC milling machine formed by modifying an ordinary milling machine and adding a simplified CNC system. Low cost, poor automation and functionality, and low precision. Can be used for the machining of planar curve and planar cavity parts.

(2) Ordinary CNC milling machine: works with three coordinate linkage, and has great potential for processing various complex flat, curved, and shell parts.

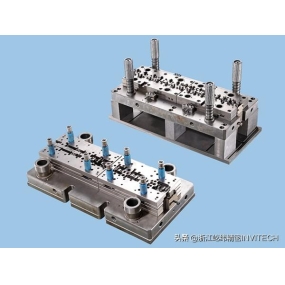

2. CNC copying milling machine

CNC profile milling machines are mainly used to process various complex cavity molds or workpieces, and have better processing effects for some difficult irregular three-dimensional surfaces and workpieces composed of complex boundaries.

3. CNC tool milling machine

A CNC tool milling machine is a type of milling machine that is formed by modifying the mechanical transmission system of a machine tool and adding a CNC system on the basis of a regular tool milling machine. Mainly used for processing various fixtures, cutting tools, and complex flat and curved parts.

There are several methods for calculating the cost of CNC milling machine processing, and the calculation of working hours is the most commonly used and simplest method in production.

1. Working hour calculation: Generally, CNC milling machines cost around 60 yuan/hour for processing. If the processing is difficult, the price will also increase.

2. Equipment calculation: The higher the precision and scale of the equipment used, the more expensive the processing cost. Usually 30/hour -100 yuan/hour. However, due to the varying prices in different regions, there may also be some differences.

3. Processing accuracy: The higher the processing accuracy of the equipment, the more expensive its cost, and correspondingly, the higher its processing fee.

4. Machine performance: ordinary CNC milling, high-speed milling, 3+2 CNC milling, five axis CNC milling, with price differences. For example, regular high-speed milling is around 100/hour, and the normal range for five axes is around 300/hour.

In addition to the specific quotation methods, multiple aspects need to be considered when making a quotation: raw material costs (settled based on raw materials), heat treatment costs, surface treatment and pretreatment costs, mechanical processing costs (settled based on the required machining hours of the process flow), outsourcing processing costs, auxiliary material costs (including depreciation of cutting tools, measuring tools, equipment, sandblasting, painting, etc.), labor and electricity costs, transportation costs during the processing and manufacturing process, finished product inspection and non-destructive testing, material testing and other costs, reasonable profits, reasonable allocation of mold costs, reasonable allocation of various management costs, freight and taxes.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque