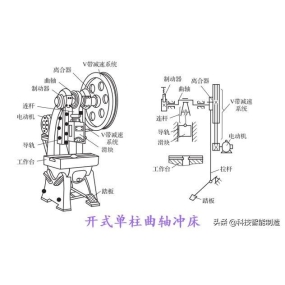

Do you know how to quote for Metal Stamping parts? In fact, the method of quoting for metal stamping processing parts is very simple. The quoted content includes: metal material cost, stamping mold cost, stamping mold cost, fixture cost, stamping cost, machining cost, surface treatment cost, etc. Understanding these costs can provide a quotation. Below, we will provide a detailed explanation of how each expense is obtained.

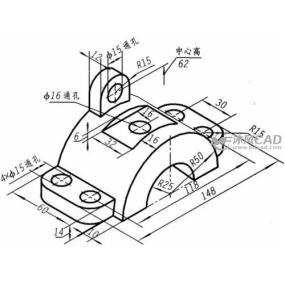

The cost of metal materials used in metal stamping processing: open the plan of the stamping part and calculate the unfolded length of the workpiece; Then use the calculation formula to calculate the unit price of length, width, thickness, density (yuan/Kg) (1.1-1.2)/10 (loss), and calculate the cost of the material.

The calculation method for stamping die cost: estimate the area of the convex and concave dies of the stamping die based on the shape of the part, with a margin of 5cm on one side and 3-5cm on the height. Check the standard of the mold frame based on the size of the die.

Stamping cost: calculated by tonnage. (0.8-1) yuan/60 tons, 1.2 yuan/80 tons. The fixture and machining costs used in metal stamping processing are not significant, so they will not be included in the calculation here.

Surface treatment fee: 0.6 yuan/decimeter for oxidation (there may be slight discrepancies in quotes from various manufacturers); Spray painting; Silk screen printing; spray; Galvanized surface. Gross profit: controlled between 20-30%.

Stamping processing fee quotation, confirm the raw material price. The width, step distance, and thickness of the first set of cutting materials determine the weight of the blank. Determine the material price of the product based on the selling price of materials in the market.

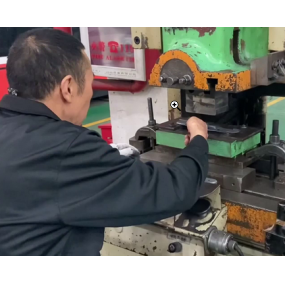

Confirm the stamping cost, as a product is composed of multiple processes, and each process may use different tonnage presses. You can make corresponding quotations according to your company's regulations.

Is your company's quotation also based on this method? If different, what is your company's pricing method? Welcome to leave a message and share!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque