How much has the price of chips fallen now?

For example, the price of an L9369-TR chip from STMicroelectronics in China was around 3500 yuan per chip in the third and fourth quarters of last year, but now it has dropped to around 670 yuan, a significant decrease.

There is also a chip model STM32F103C8T6, which was previously priced at around 200 yuan but is now only sold for 21.5 yuan, nearly one tenth of its original price.

A chip dealer stated that there is sufficient stock available, and orders can be shipped immediately.

Doesn't this feel wrong? Didn't we have a chip shortage before? Why did the price plummet?

Let's first talk about why there is a shortage of chips. This topic has been discussed several times in previous videos, and the reasons are multifaceted. For example, initially, some major wafer fabs experienced accidents, leading to production shutdowns and reductions. At the same time, the epidemic caused disruptions in the semiconductor supply chain, leading to the rise of remote work and online classes from home. The demand for electronic products has surged, resulting in a shortage of supply and a high demand for chips.

It is precisely because of the huge gap in chips that wafer fabs around the world are expanding and building, constantly increasing production capacity. After more than two years, chip supply has actually begun to improve. At the same time, due to the complex international situation, global demand for electronic products is gradually slowing down. In the first period, TSMC Chairman Liu Deyin publicly stated that fields such as smartphones, laptops, and televisions were all affected.

For example, according to data released by market research firm Canalys, global smartphone shipments reached 311.2 million units in the first quarter of 2022, a year-on-year decrease of 11%.

According to the latest report from Counterpoint Research, in May 2022, global mobile phone market sales decreased by 4% month on month and 10% year-on-year, to 96 million units. This is also the second time in 8 years that monthly mobile phone sales have fallen below 100 million units.

Similarly, in China, the situation is the same. According to a report by the China Academy of Information and Communications Technology, the total shipment of mobile phones in the domestic market in the first quarter of this year was 69.346 million units, a year-on-year decline of 29.2%.

According to data from the China Academy of Information and Communications Technology, the domestic shipment of mobile phones in June was approximately 25.664 million units, a year-on-year decrease of 10.4%.

In fact, it has been reported for a while that Chinese Android phone manufacturers cut orders for about 170 million phones as early as March, followed by another 100 million orders. Mobile phone brands such as Xiaomi, VIVO, and OPPO have informed their suppliers that orders will continue to decrease in the coming seasons.

In addition, even the world's number one Samsung has reduced its shipment target for this year by about 10% to 275 million units.

Meanwhile, in terms of personal computers, data released by market research firm Gartner shows that the global PC market shipped 77.9 million units in the first quarter of 2022, a decrease of 6.8% compared to the first quarter of 2021.

Another factor is television sets. According to the "Monthly Global TV Brand Shipment Data Report" by Ove Rui Wo, the global TV shipment volume in the first quarter of 2022 was 44.9 million LCD TVs and 1.5 million OLED TVs, a year-on-year decrease of 6.1%, marking the third consecutive quarter of decline.

In addition, according to the "2022 Half Year Report on the Domestic Color TV Market" released by Ovei Ruiwo, the retail scale of omnichannel color TVs in China was 16.72 million units in the first half of the year, a year-on-year decrease of 6.2%.

It can be seen that the sales of these major electronic products are declining, resulting in less product production and naturally less chip demand.

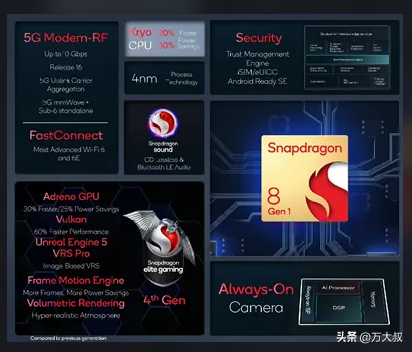

For example, Qualcomm has reduced its orders for Snapdragon 8 chips by 10% to 15% and plans to lower the prices of older Snapdragon 8 series chips by 30% to 40% after the new Snapdragon 8 chips are shipped.

In addition, MediaTek has also reduced orders for entry-level and mid-range 5G chips signed with suppliers by 30% to 35% in the fourth quarter of 2022.

In short, with the rise and fall of this trend, the supply of chips has gradually exceeded demand, so the price has fallen accordingly, which is only normal.

Of course, there is also an imbalance in the supply and demand of chips. Overall, the mid to low end chips have been greatly alleviated, while in terms of high-end chips, due to the high difficulty of manufacturing processes, only a few manufacturers in the world have the ability to produce them, so the production capacity of these chips is still tight.

Furthermore, from an industry perspective, the supply pressure of automotive chips is still significant, which is also due to the rapid development of new energy vehicles. For example, a traditional fuel powered vehicle only requires 500-600 chips, while an intelligent new energy vehicle may require over 2000 chips.

Regarding this, Shen Hui, founder, chairman, and CEO of WM Motor, has stated that the chip cost of smart electric vehicles has exceeded that of battery packs, and the industry track of electric vehicles will shift from batteries to chips.

Moreover, Mercedes Benz CEO Kang Linsong has also stated that it is expected that the shortage of automotive chips will continue until 2023.

In short, with the continuous changes in the supply and demand relationship of chips, the chip problems in most industries have been well alleviated. It is believed that the market will return to stability soon. However, with the continuous launch of new production capacity by major wafer fabs, the "chip shortage" in some industries may gradually evolve into a "chip panic". Regarding this issue, we also need to pay attention to it. After all, China has invested a lot of manpower and material resources in the semiconductor field, and in the present and future, we can only seek opportunities in the mid to low end chip market, which may become saturated. Of course, this is also a necessary path for the development of domestic semiconductors, as the demand for mature process chips far exceeds that of high-end process chips.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque