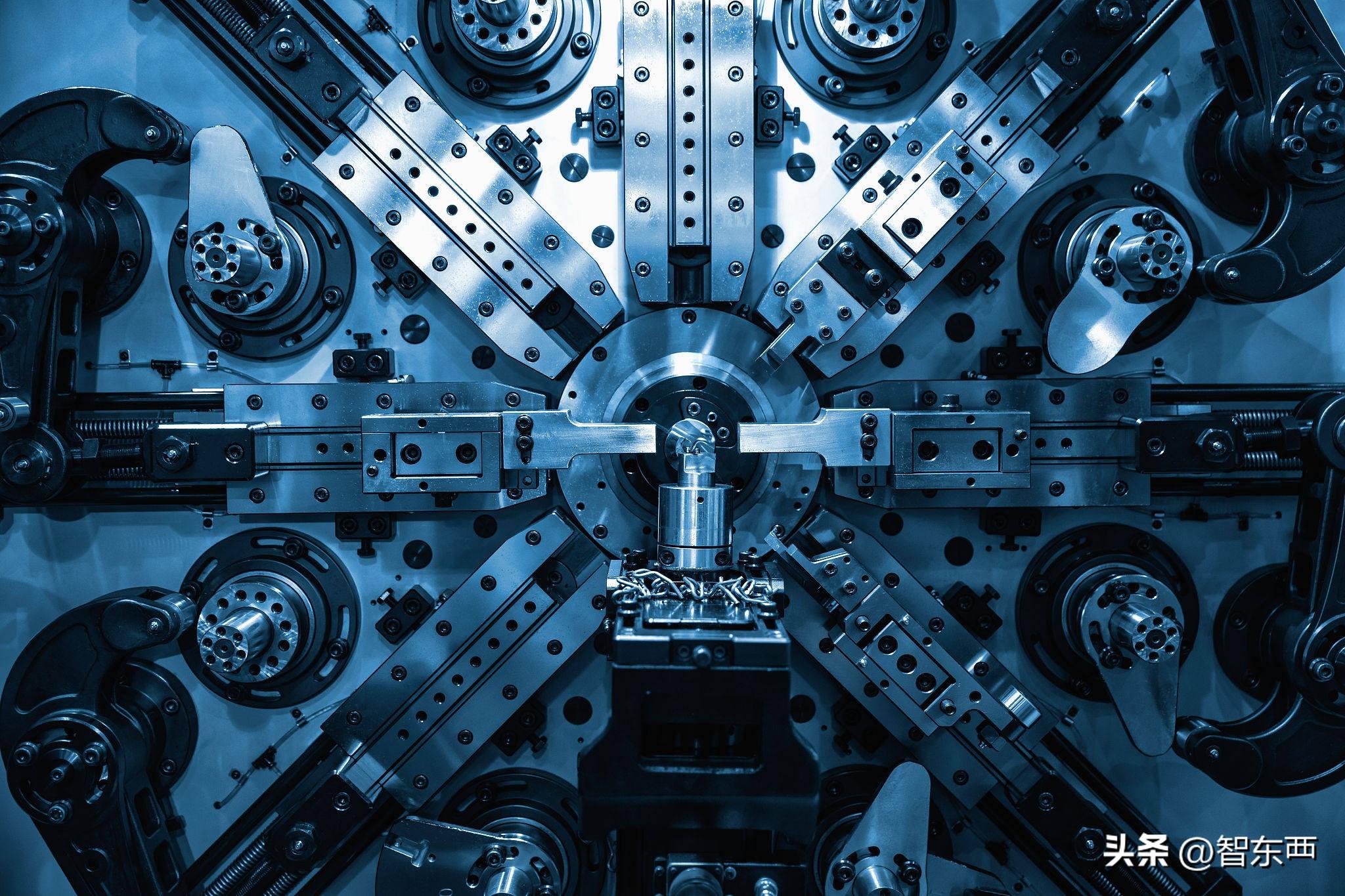

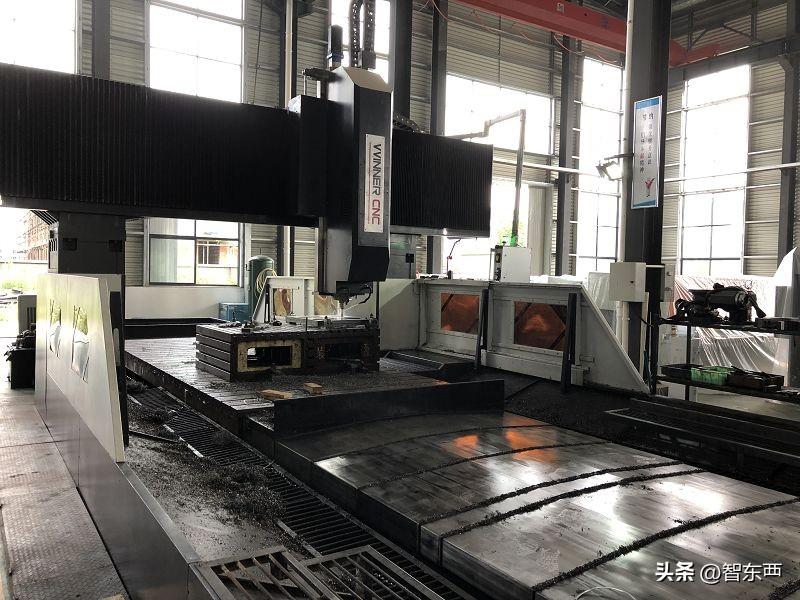

CNC (Computer Numerical Control) is a CNC Machining technology controlled by a computer, which can achieve high-precision and high-efficiency machining processes. The principle and technology of CNC machining are as follows:

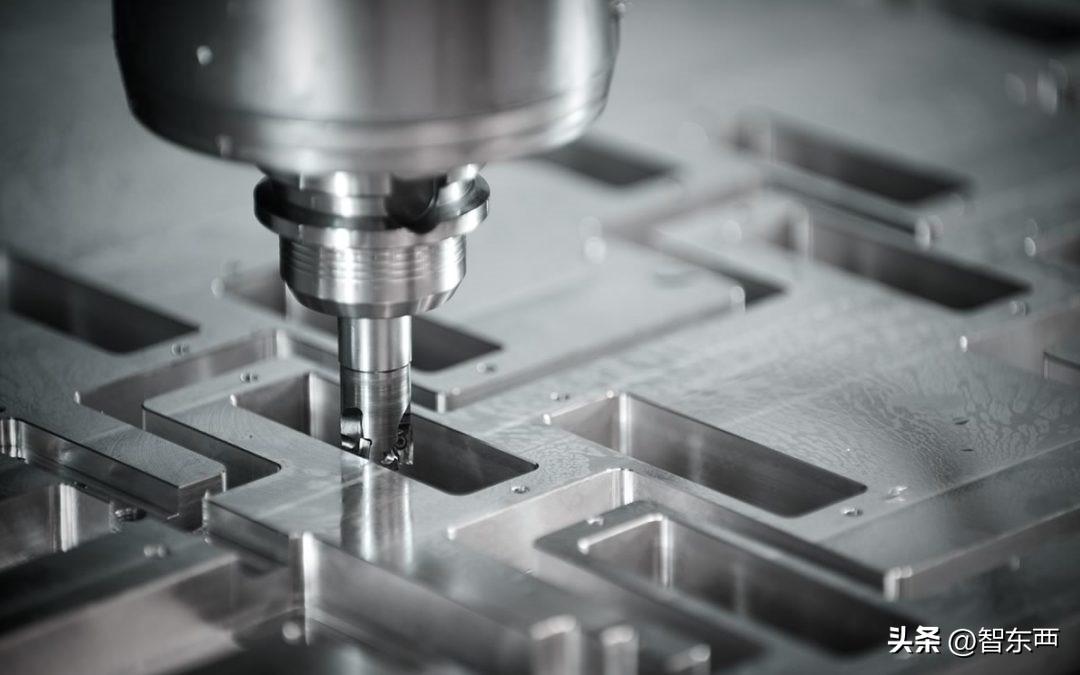

1. Numerical control programming: Firstly, it is necessary to write machining programs using specialized numerical control programming software. The machining program includes information such as machining path, cutting parameters, tool path, etc.

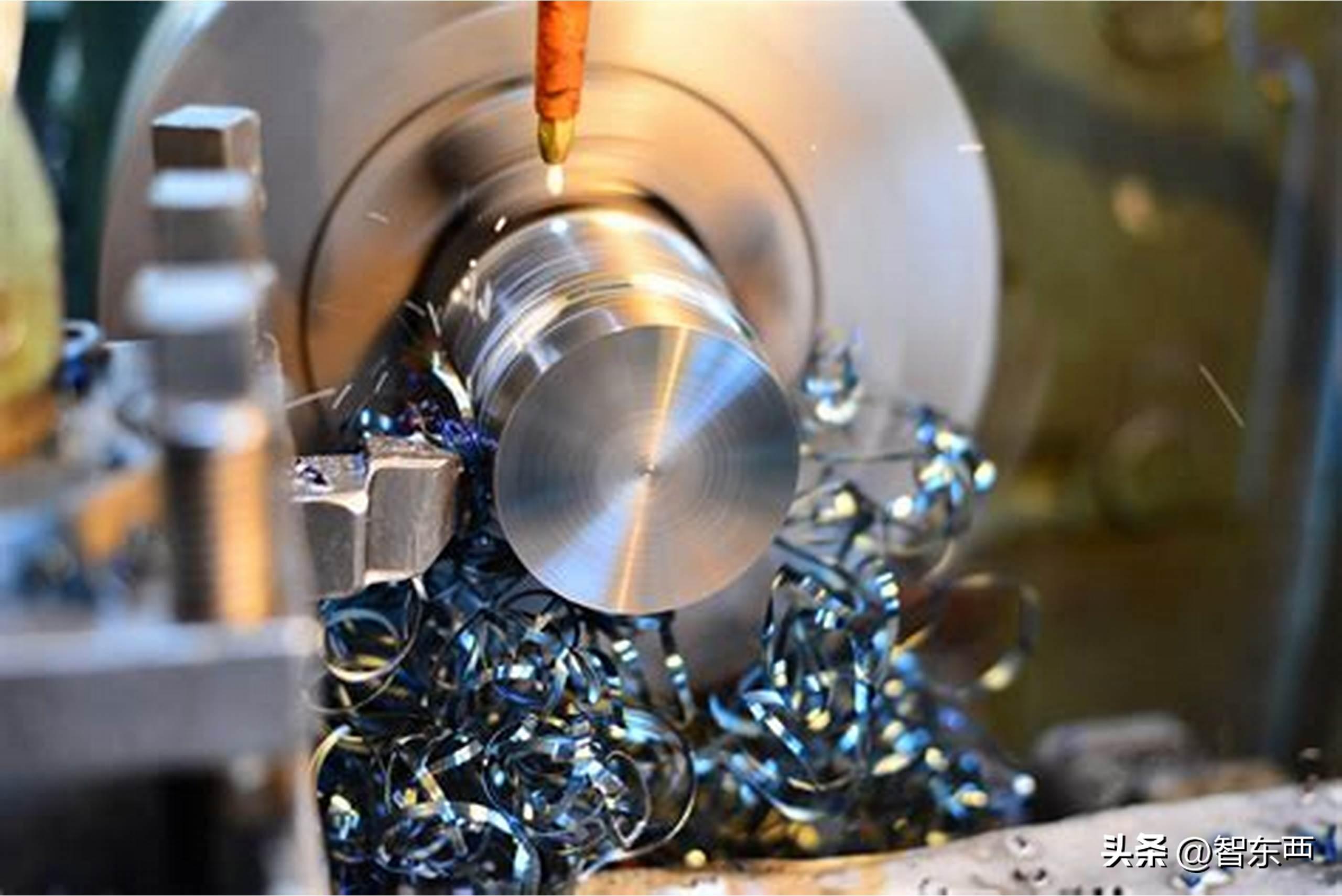

2. Machine tool control: The pre written machining program is loaded into the control system of the CNC machine tool. The control system controls various power components on the machine tool, such as the spindle, feed axis, and cutting tools, through the computer based on program instructions to achieve machining operations.

3. Machining process: During the machining process, the machine tool processes according to the path and cutting parameters specified in the machining program. The control system controls the movement and cutting speed of the tool according to program instructions, gradually cutting the raw material into the desired shape of the workpiece.

4. Automation control: CNC machining can achieve automation control. Through pre written machining programs, machine tools can automatically perform machining operations, reduce manual intervention, and improve production efficiency and machining accuracy.

As for the number of axes, it represents the degree of freedom of motion and machining capability of the CNC machine tool. Common CNC machine tools have different numbers of axes such as 3-axis, 4-axis, 5-axis, etc. The more axes there are, the greater the degree of freedom of the machine tool in space, enabling more complex machining operations.

-3-axis machine tools: typically have three axes, X, Y, and Z, representing horizontal, vertical, and longitudinal motion, respectively. Suitable for flat and simple three-dimensional processing.

-4-axis machine tool: Adding a rotating axis on top of the 3-axis, usually rotating around the Z-axis. It can achieve rotational machining of workpieces.

-5-axis machine tool: Adding a tilt axis on top of the 4-axis, it can achieve tilted machining of workpieces. Can be used for processing complex surfaces, such as automotive parts, aircraft parts, etc.

The more axes there are, the stronger the machining capability of the machine tool, which can achieve more complex and precise machining operations. However, at the same time, an increase in the number of axes will also increase the complexity and cost of the machine tool. The selection of the appropriate number of axes needs to be determined based on specific processing requirements and budget.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque