Today, I will share with you the main factors to consider when choosing a five axis machining center, using the industry-leading Makino five axis machining center as an example. I will provide you with a detailed list of those who don't know

01

Structure determines equipment performance

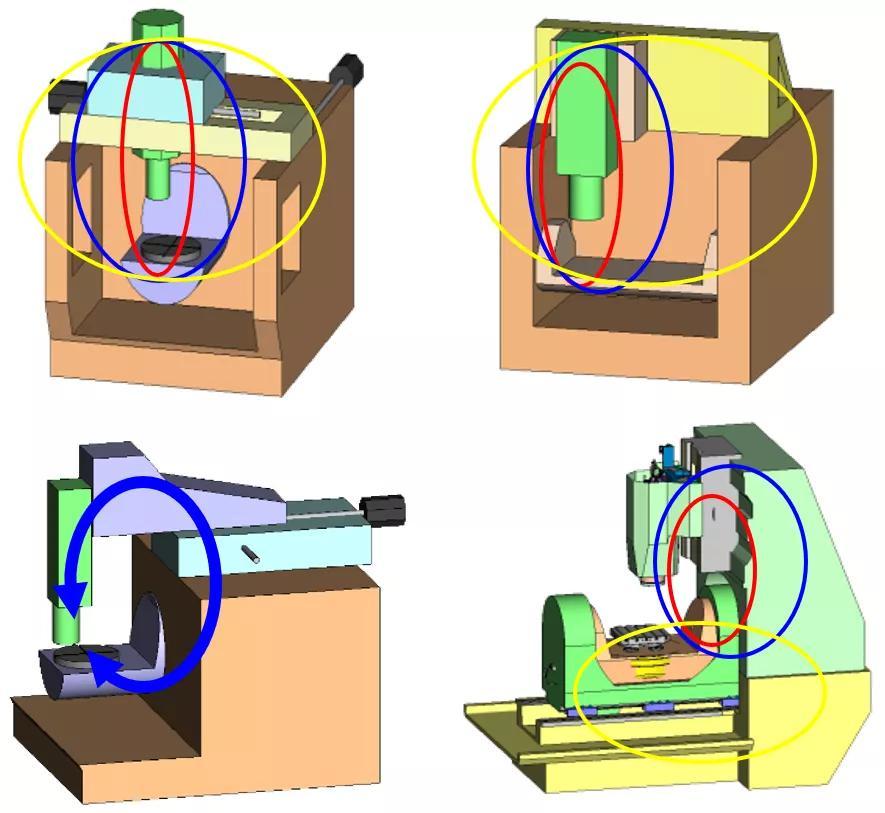

There are various structures of five axis machining centers, and the structural design of the machine tool determines the performance of the equipment, including rigidity, machining accuracy, stability, operability, and so on.

The following aspects should be mainly considered:

1) The linear axis does not merge or superimpose when moving

2) Equipment with short cutting circuits has good rigidity

3) Is the tilting rotation axis a DD motor

4) Is it 5-axis linkage

5) 5-axis proximity

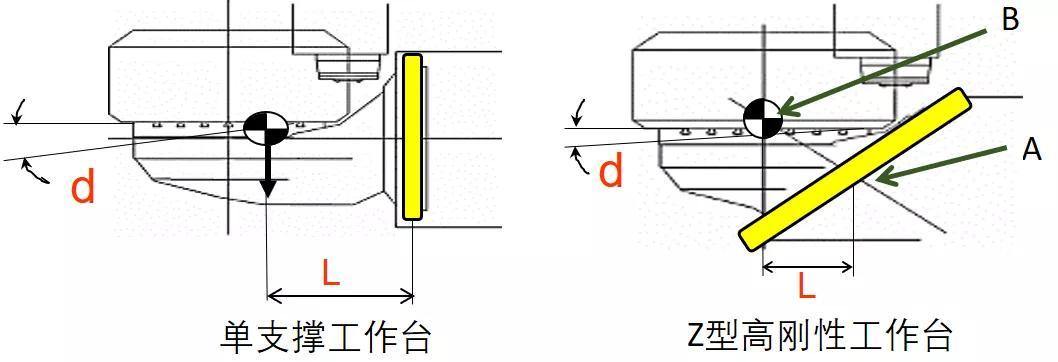

Makino's D200Z/D800Z/a500Z series five axis machining center adopts a "Z" - shaped high rigidity worktable structure, as shown in the figure below. The worktable does not require support at both ends, with large diameter inclined bearings and a workpiece center of gravity B within A. Compared with traditional single support structures, the bending amount d is extremely small and the force arm L is shorter.

This inclined axis structure can achieve high-precision machining comparable to 3-axis machining centers. Even when loading and rotating heavy components, the deflection of the workbench can be controlled to a minimum. At the same time, high rigidity bearings and direct drive motors can achieve high-precision and smooth rotation with minimal vibration. Additionally, it has excellent spatial proximity.

02

Tilt rotation axis accuracy

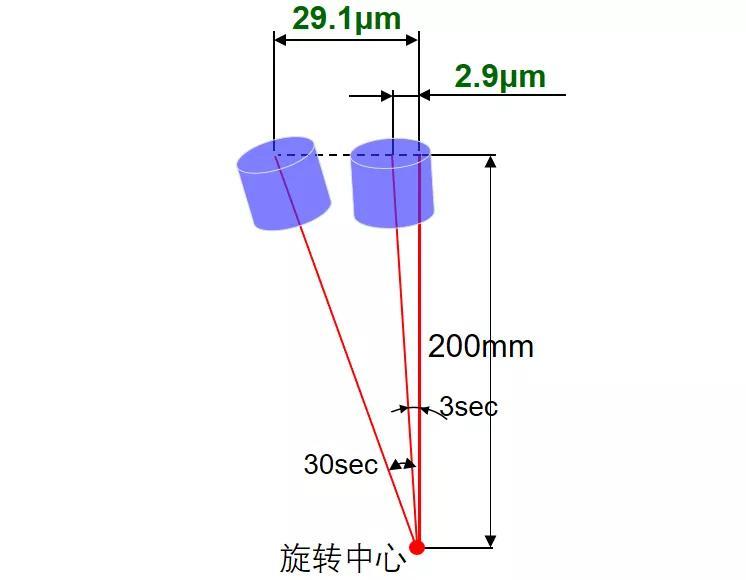

The machining accuracy of machine tools is directly affected by the accuracy of the rotating axis. To understand the actual impact of tilted rotating axis accuracy on machining accuracy, use the Makino D800Z machine tool.

1= 60′

1′= 60″

1=3600″

The minimum resolution of the B/C axis of the D800Z machine tool is 0.0001 degrees, which is 0.36 inches, and the positioning accuracy is 3 inches. Through the following calculation diagram, we can know the resulting accuracy error.

03

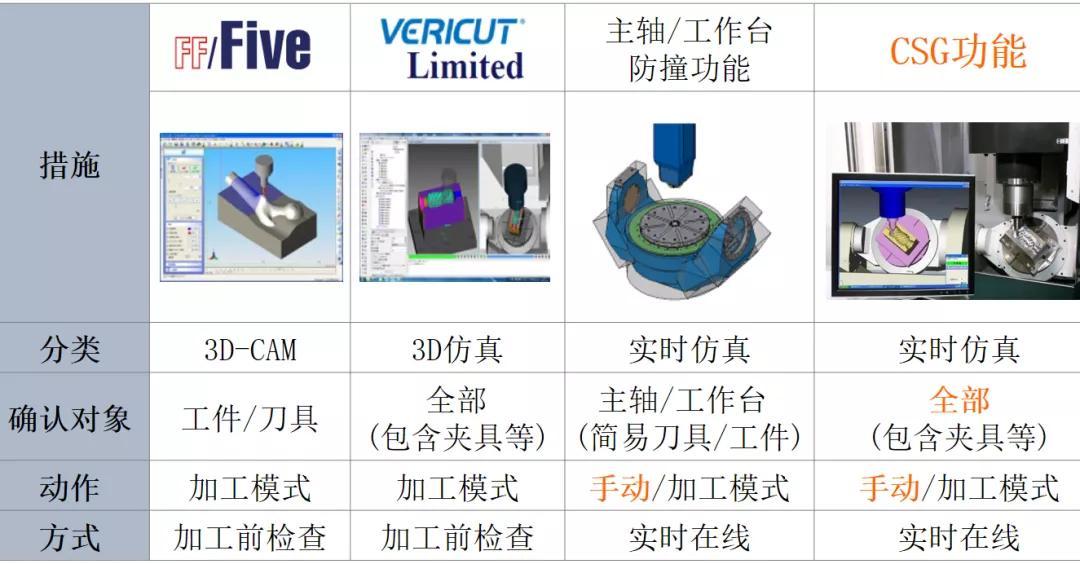

Interference collision avoidance

Interference and collision avoidance are important issues in 5-axis machining. In addition to using computer-based software for interference inspection, Makino's 5-axis machining center is equipped with online real-time simulation CSG function, which can prevent interference even in manual mode.

The online real-time simulation CSG function can check for possible tooling errors or tool length setting errors before processing, in order to minimize emergency stops during operation. During operation, based on pre calibrated and adjusted data, as well as coordinates, offset values, and other positional information read from the CNC control device, the possibility of interference is predicted. Once the machine tool stops running, the status screen can be displayed in real time, and the predicted interference parts and axis movement direction can be confirmed.

04

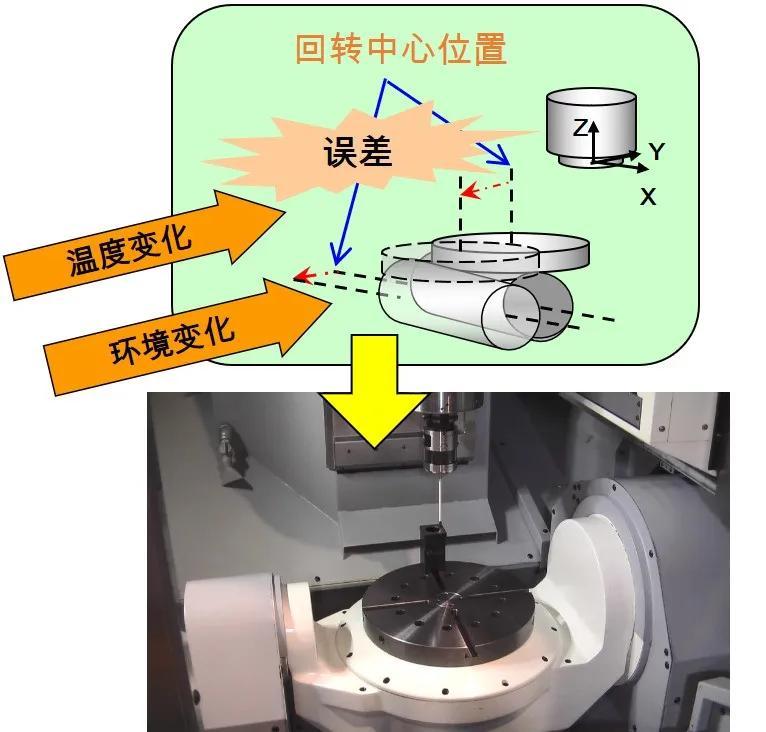

Rotation center correction

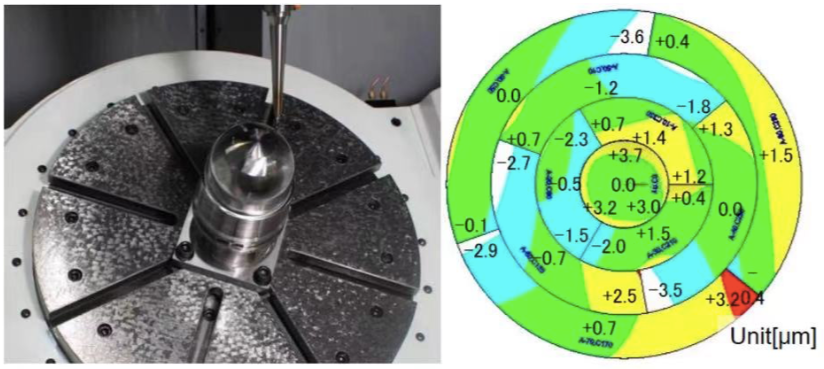

The change in rotation center caused by environmental and temperature changes can affect the precision of five axis machining. It should be able to automatically calibrate through the probe, verify the machining accuracy of 3-axis/indexing/5-axis machining, and ensure that the tool error is less than or equal to; 4 μ m.

Automatically calibrate the 5-axis rotation center using a probe

3-axis/indexing/5-axis machining accuracy verification machining

05

Linkage accuracy

The linkage accuracy of a five axis machining center is a reflection of the results of multiple factors. Taking Makino D200Z as an example, provide processing cases to provide reference for linkage accuracy.

Processing equipment: D200Z

CAM:FFCAM

Workpiece material: NAK80 (40HRC)

Workpiece size: 140x140x35mm

Mold cavity: Clear angle R0.22mm, depth 20mm

Processing time: 1H35min/pocket

Cutting tools: 7 pairs and 6 types

Linkage accuracy: Position accuracy 2 μ m, shape accuracy 3 μ m

06

Process support

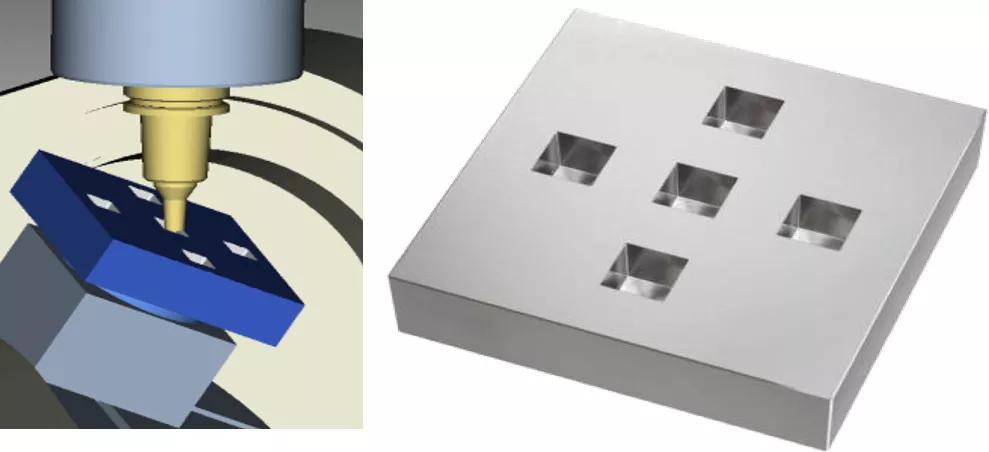

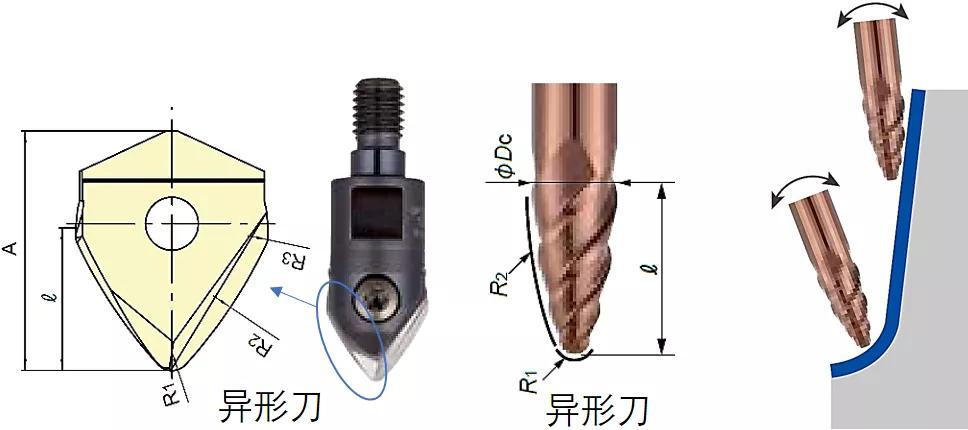

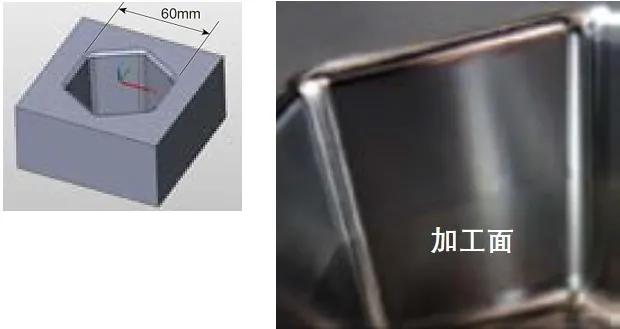

The machining process of a five axis machining center determines whether the equipment's performance can be maximized. For example, using irregular cutting tools can significantly improve machining efficiency.

Processing case: Efficiency increased by 6 times!

Material: YXR33 (58HRC)

Shape and size: as shown in the figure below, depth 30mm, draft angle 2, clearance angle R3mm

Alright, that's all for the editor to share here! Some students say that even after reading an article, they still can't understand it, just like watching TV. Learning UG programming well is actually very simple, as long as you learn systematically from experienced people, communicate more with friends, colleagues, and classmates. The harder you work. The luckier! Move everyone's little finger to forward to your own circle of friends to benefit more partners

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque