Regarding the issue of dimension annotation, many new technical personnel in the industry hold a drawing and want to annotate dimensions, but do not know how to start and how to express them perfectly. Each engineer's style of annotating drawings is different, but is there a popular method or a method suitable for beginners?

Generally speaking, drawings are not perfect, and anyone who creates any form of drawing can always pick out various flaws. Even if you think there are no problems with a drawing, during the leader's review, you are not asked to modify some harmless issues or if you think it is correct but have to modify it according to the leader's instructions.

For drawings, generally speaking, the more information there is, the more redundancy there is, and to a certain extent, it can also affect information exchange.

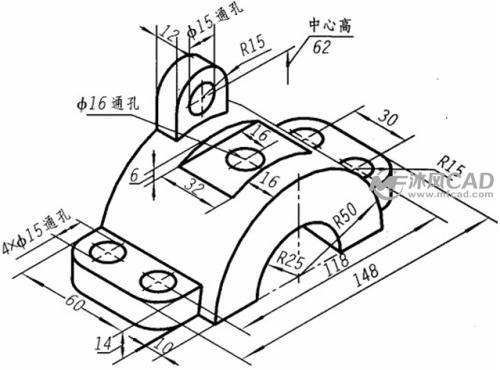

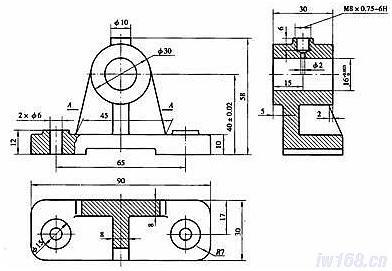

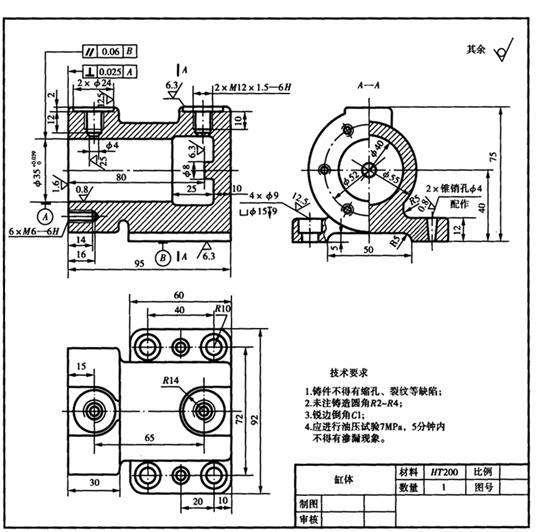

In order to annotate dimensions reasonably, it is necessary to understand the function of the parts, their assembly position in the machine, and the processing methods used, so as to select appropriate dimensional benchmarks and annotate dimensions reasonably.

Once you understand this rule, even the most complex product part dimension labeling will not be at a loss

Classify and explain various complex mechanical component drawings, how to label dimensions reasonably

Principle of reasonable dimensioning: 1. Important dimensions should be directly indicated

2. Avoid labeling as a closed dimensional chain

3. Consideration should be given to the convenience of measurement

4. Should comply with the processing sequence

5. Consider processing methods

6. Dimensional annotation method for common holes on parts

Common knowledge of mechanical drawing: dimensioning of part drawings, selection of benchmarks, and principles of reasonable annotation

The basic points to note for other drawings are:

1. Fill in all possible fields in the frame, including name, number, scale, material, unit, weight, surface treatment, signature, etc.

2. Mark the dimensions and tolerances one by one, while highlighting the key points (3F dimensions, quality control points). Tolerance needs to be studied in conjunction with the company's production process capabilities, and cannot be marked for the sake of tolerance.

3. Communicate with the users of the drawings (processors, quality controllers, bosses, etc.) to discuss and approve some of their important feedback, which can be written on the drawings.

4. Well done. The view should generally be as large as possible; Use multiple colors, such as using one color for dimension marking and another color for positional tolerance marking; Sometimes using dimension chains for annotation can reduce the clutter of drawings.

5. Try to start making engineering drawings from 3D models, and include individual views that can better showcase the overall style of the components in the drawings.

Resolve the issue of increased annotation size in CAD local enlargement icons

Definition, annotation, and interpretation of various positional tolerances - truly comprehensive

Introduction to Calculation and Application of Size Chain: When designing and annotating dimensions in products, it is necessary to consider

The difference between three annotation methods: 10 (-0.2,+0.2) 9.8 (0,+0.4) 10.2 (0, -0.4)

Detailed explanation: Gap, transition, interference fit, base hole system, base axis system, fitting code and annotation examples

Mechanical drawing: Which of the four identical hole markings 4-10 and 410 is correct?

Don't say you can't understand the drawings anymore! Non technical personnel related to machinery should take a good look at the most basic drawing annotations

Mechanical Drawing: Detailed Explanation of the Concept and Annotation Method of Surface Roughness

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque