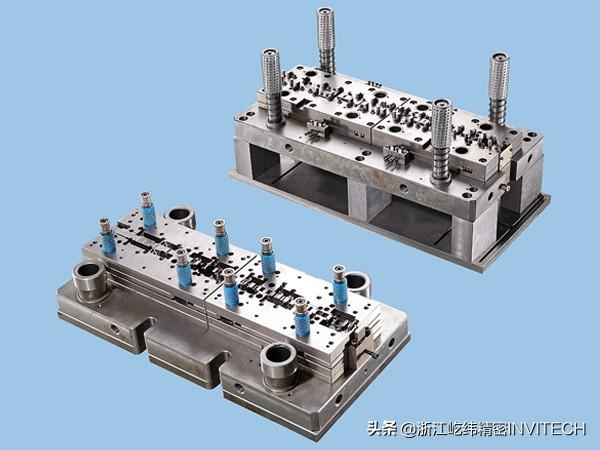

Metal Stamping parts rely on molds and stamping machines to apply pressure to metal materials, causing deformation and forming various shapes of products that we need. So what are the characteristics of our stamping parts company when assembling stamping molds? Let's take a look.

The assembly of metal stamping molds is suitable for centralized assembly, and the assembly process often uses repair and adjustment methods to ensure assembly accuracy. Because some parts that make up the mold entity are independently processed according to the dimensions and tolerances marked on the drawing during the manufacturing process, these parts are usually directly assembled; Some parts can only be machined according to the dimensions indicated on the drawing during the manufacturing process, and relevant dimensions need to be coordinated; Some require preparation or assembly processing before entering the assembly process, while others require coordination through preparation during the assembly process. The dimensions marked on the drawings are only for reference. Centralized assembly can achieve high assembly accuracy and reduce machining requirements for components with low precision.

Zhejiang Yiwei Precision is a manufacturer specializing in precision metal stamping, stretching, metal insert injection molding, and precision injection molding. With 36 years of experience in customized processing, we support mold development and design. We are happy to share our understanding of metal stamping processing with you and provide solutions that meet your economic needs for stamping and forming.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque