In order to control the cooling temperature of refrigeration equipment such as refrigerators and air conditioners and the heating temperature of electric heating devices, temperature controllers (referred to as thermostats) are installed on both refrigeration equipment and electric heating devices.

1、 Classification of Temperature Controllers

1. Classification based on control methods

Thermostats can be divided into two types based on their control methods: mechanical and electronic. Mechanical temperature controllers detect temperature through temperature sensors and control the compressor power supply system through mechanical systems, thereby achieving temperature control. Electronic temperature controllers detect temperature through negative temperature coefficient thermistors, and then control the compressor power supply system through relays or thyristors to achieve temperature control.

2. Classification based on material composition

Thermostats can be divided into various types based on their material composition, such as bimetallic thermostats, refrigerant thermostats, magnetic thermostats, thermocouple thermostats, and electronic thermostats.

3. Classify by function

Temperature controllers can be divided into various types based on their functions, such as refrigerator temperature controllers, air conditioner temperature controllers, rice cooker temperature controllers, electric water heater temperature controllers, shower temperature controllers, microwave temperature controllers, barbecue oven temperature controllers, etc.

4. Classify according to the working mode of the contacts

Thermostats can be divided into two types based on the working mode of the contacts: dynamic closing type (normally open contacts) and dynamic breaking type (normally closed contacts).

2、 Identification and detection of bimetallic thermostat

Bimetallic thermostat, also known as temperature control switch, is mainly used to control the heating temperature of electric heating devices. The physical appearance of a common bimetallic thermostat is shown in the following figure.

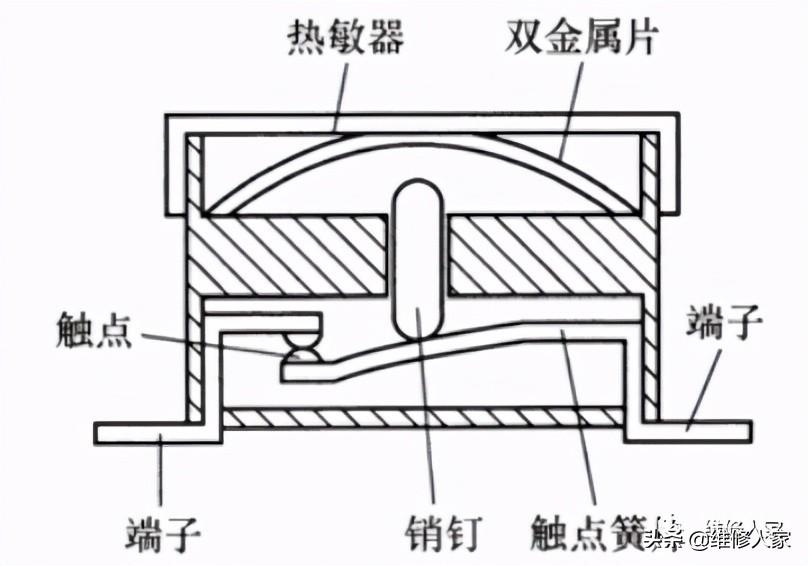

1. Composition and principle of bimetallic thermostat

The bimetallic thermostat consists of a thermistor, bimetallic strips, pins, contacts, contact springs, etc., as shown in the following figure. After the electric heating device is powered on, it begins to heat up. When the temperature detected by the thermostat is low, the bimetallic strip bends upwards without contacting the pin, and the contact closes under the action of the contact spring. As the heating continues, when the temperature detected by the thermostat reaches the set value, the bimetallic strip deforms and presses down, causing the contact spring to bend downward through the pin, resulting in the release of the contact. The heater stops working due to lack of power supply, and the electric heating device enters the insulation state. As the insulation time prolongs, the temperature begins to decrease. After the temperature controller detects it, its bimetallic strip resets, and the contacts are attracted by the spring spring. The power supply circuit of the heater is reconnected to start heating. By repeating the above process, automatic temperature control is achieved.

Tip: The control temperature point of the bimetallic thermostat used in some rice cookers can be adjusted. By adjusting the adjustment screw on the bimetallic thermostat, the pressure acting on the contact can be changed in advance, thereby changing the temperature point of the action.

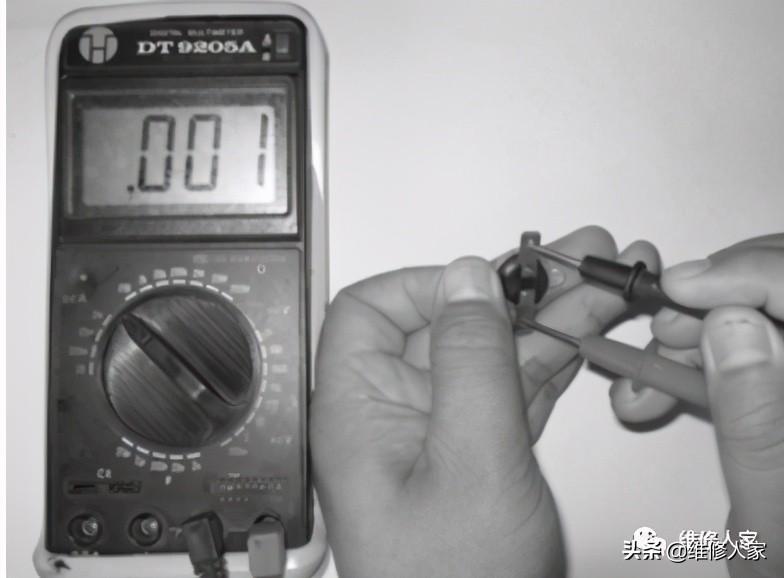

2. Testing of bimetallic thermostat

As shown in the figure below, when not heated, use the "R1" position of the multimeter to measure the resistance between the wiring terminals of the bimetallic thermostat. If the resistance is infinite, it indicates that it is open circuit; And when the temperature it detects reaches the nominal value, the resistance value cannot be infinite and remains 0, indicating that the internal contacts are stuck.

3、 Identification and Testing of Magnetic Temperature Controllers

Magnetic temperature controller, also known as magnetic steel temperature limiter, commonly known as magnetic steel, is mainly used in rice cookers to control the cooking time of the rice cooker. The physical appearance of a common magnetic thermostat is shown in the figure.

1. Composition of magnetic thermostat

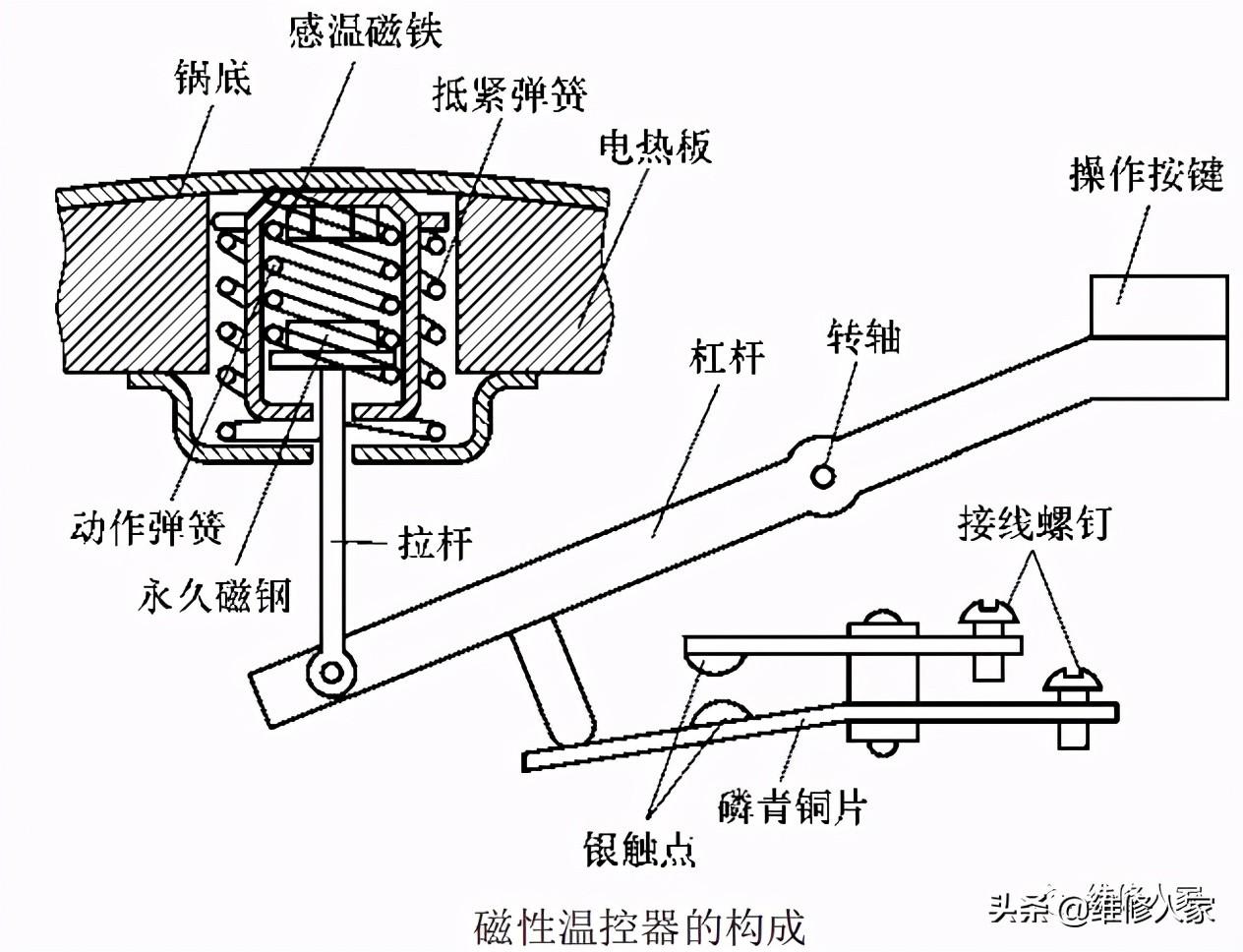

The magnetic thermostat is composed of temperature sensing magnets, springs, permanent magnets, pull rods, etc., as shown in the following figure.

2. Working principle of magnetic thermostat

After pressing the operation button of the rice cooker, the permanent magnet inside the magnetic thermostat overcomes the pushing force of the action spring under the action of the lever, moves upward and attracts the temperature sensing magnet. The silver contact of the assembly switch is closed under the action of the phosphor bronze sheet, connecting the power supply circuit of the rice cooker heating plate, and it starts heating. As the heating continues, the temperature at the bottom of the pot gradually increases. When the temperature reaches the set value of the temperature sensing magnet, the magnetism of the temperature sensing magnet disappears, and the permanent magnet resets under the action of the action spring. The contact is disconnected through the lever, and the heating plate stops working due to lack of power supply. The rice cooker enters the insulation state.

4、 Identification and Testing of Refrigeration Temperature Controllers

The refrigeration temperature controller (mechanical type) is mainly used in ordinary direct cooling refrigerators. Its main function is to control the operation and stop time of the compressor, and achieve refrigeration control. The physical appearance of a common refrigeration thermostat is shown in the following figure.

1. Composition of refrigeration temperature controller

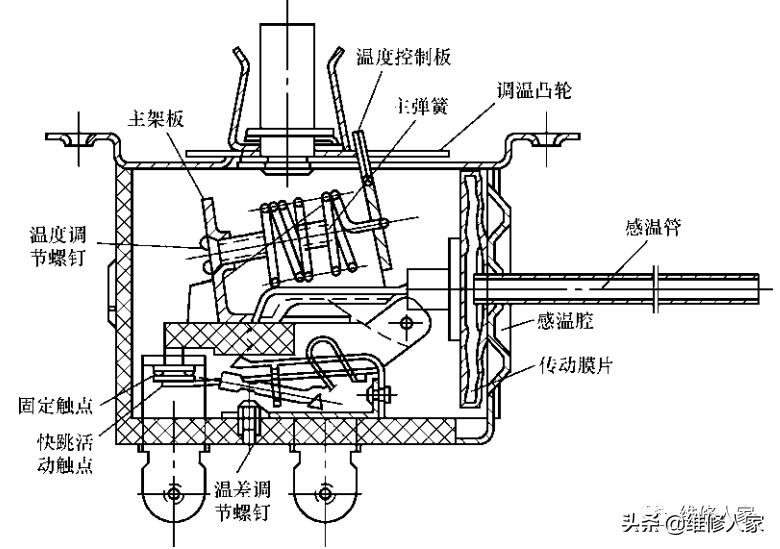

The refrigeration temperature controller (mechanical type) is mainly composed of a temperature sensing tube, a transmission diaphragm, temperature adjustment screws, contacts, etc., as shown in the following figure

2. Working principle of refrigeration temperature controller

When the temperature inside the refrigerator is high, the temperature of the temperature sensing tube installed on the surface of the refrigerator evaporator also increases. The expansion of the temperature sensing agent inside the tube increases the pressure, causing the transmission diaphragm in front of the temperature sensing chamber (temperature sensing bag) to move forward. When it reaches a certain temperature, the moving contact (fast jumping movable contact) and the fixed contact close, connecting the power supply circuit of the compressor motor. The compressor starts to operate, and the refrigerator enters the cooling state. As refrigeration continues, the surface temperature of the evaporator gradually decreases, and the temperature and pressure of the temperature sensing tube also decrease. The transmission diaphragm shifts backward. When it reaches a certain temperature, the moving contact separates from the fixed contact under the action of the main spring, cutting off the power supply circuit of the compressor, stopping the compressor, and ending refrigeration. Repeat the above process, the temperature controller controls the operation time of the compressor to ensure that the temperature inside the box changes within a certain range. The control of the temperature inside the refrigerator is achieved by rotating the temperature adjustment screw. When the temperature range does not meet the requirements (there is an error in temperature control), it can be corrected by adjusting the temperature adjustment screw. However, do not adjust it during general maintenance, especially for thermostats with defrosting devices, to avoid unnecessary trouble.

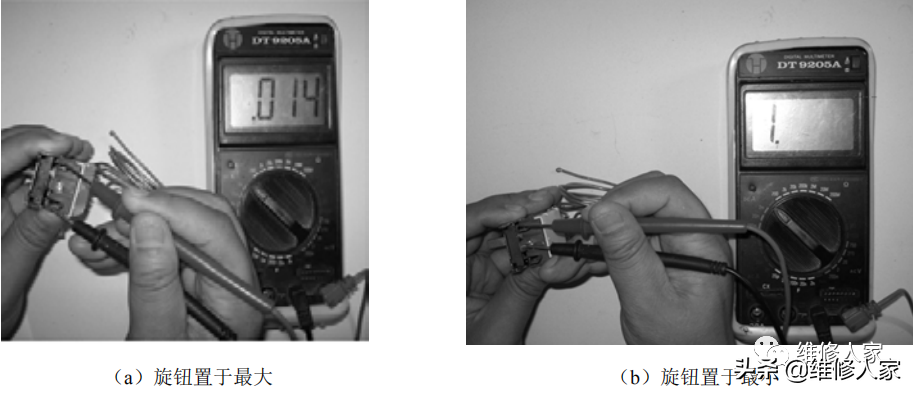

3. Testing of refrigeration temperature controller

After turning the knob on the thermostat to the maximum, use the diode mode (on/off measurement mode) of the digital multimeter to measure the value between the contact terminals as 0 or close to 0, and the buzzer will sound, as shown in (a) above; If the knob of the thermostat is turned to the maximum and the value cannot be 0, it means that the contacts of the thermostat cannot be closed. When the knob of the thermostat is turned to its minimum, the value should be infinite, as shown in (b) above; If the value is 0, it indicates that the contacts inside the thermostat are stuck.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque