01

Processing equipment

1. Ordinary lathe:

Lathes are mainly used for machining shafts, discs, sleeves, and other workpieces with rotating surfaces, and are the most widely used type of machine tool in mechanical manufacturing. (Can achieve an accuracy of 0.01mm)

2. Ordinary milling machine:

It can process flat surfaces, grooves, as well as various curved surfaces, gears, etc., and can also process more complex profiles. (Can achieve an accuracy of 0.05mm)

3. Grinding machine

A grinder is a machine tool that grinds the surface of a workpiece. (Can achieve an accuracy of 0.005mm, small parts can achieve 0.002mm)

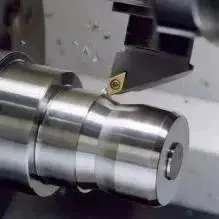

4. CNC lathe

Mainly processing bulk products, high-precision parts, etc. (Can achieve an accuracy of 0.01mm)

5. CNC milling machine

Mainly processing bulk products, high-precision parts, complex parts, large workpieces, etc. (Can achieve an accuracy of 0.01mm)

6. Wire cutting

The electrode used for slow wire is brass wire, and the middle wire is molybdenum wire. Slow wire processing has high precision and good surface smoothness. Process some precision holes, precision grooves, etc. (Slow wire can achieve an accuracy of 0.003mm, medium wire can achieve an accuracy of 0.02mm)

7. Spark machine

Electric discharge machining can process materials and complex shaped workpieces that are difficult to cut using ordinary cutting methods, without being affected by material hardness or heat treatment conditions. (Can achieve an accuracy of 0.005mm)

02

Process knowledge

1) Holes with an accuracy less than 0.05mm cannot be milled and require CNC Machining; If it is a through-hole, it can also be wire cut.

2) The precision holes (through holes) after quenching require wire cutting processing; Blind holes require rough machining before quenching and precision machining after quenching. Non precision holes can be made in place before quenching (leaving a quenching allowance of 0.2mm on one side).

3) Grooves with a width of less than 2mm require wire cutting processing, and grooves with a depth of 3-4mm also require wire cutting processing.

4) The minimum allowance for rough machining of quenched parts is 0.4mm, and the allowance for rough machining of non quenched parts is 0.2mm.

5) The thickness of the coating is generally 0.005-0.008mm, and it should be processed according to the pre plating dimensions.

03

Process working hours

Process time=preparation time+basic time

Preparation time refers to the time consumed by workers to familiarize themselves with process documents, collect blanks, install fixtures, adjust machine tools, dismantle fixtures, etc. Calculation method: Estimate based on experience.

The basic time is the time consumed to cut off the metal.

04

Quotation cost calculation method

Processing cost=(material cost+processing cost) * 1.2

The coefficient of 1.2 includes management fees

Equipment cost=(processing material cost+processing cost+purchase cost+assembly and debugging cost+design cost) * 1.2

The coefficient of 1.2 includes management fees

Material cost=weight (density * volume) * unit price (yuan/kg)

Processing fee=process hours * unit price (yuan/hour)

Japanese procurement cost (yuan)=purchase price (yen)/exchange rate

The cost of domestic procurement shall be based on the supplier's quotation

Design fee=working hours * unit price (yuan/hour)

Quotation information:

1) Lathe: 60 yuan/hour

2) Milling machine: 60 yuan/hour

3) Grinding machine: 60 yuan/hour

4) Fitter: 80 yuan/hour

5) Machining center: 60-120 yuan/hour

6) CNC lathe: 60-120 yuan/hour

7) Spark machine: 80-150 yuan/hour

8) Slow wire cutting: 60-150 yuan/hour; Starting at 80 yuan for small items, 0.06-0.08 yuan/mm2 for large items by area

9) Fine hole discharge: Carbon steel, tungsten steel, 1 yuan/mm for materials with a diameter of 0.3 or more, 2-3 yuan/mm for materials with a diameter of 0.3 or less; 0.3 and above, 1.8-2 yuan/mm

10) Management fee: Cost price * 0.2

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque