It may sound clich é, but indeed, prevention is better than cure. This is true for any manufacturing, especially in the Metal Stamping industry. Metals can be affected by wear, corrosion, environmental hazards, and other factors. Multiple processes in stamping help minimize these potential metal failures - one of which is metal surface treatment or metal finishing, which can provide further metal protection.

Understanding its application on metals (depending on its corrosiveness, potential exposure, etc.) is beneficial and essential for us. In the long run, surface treatment can save us more money and less production time. This article will delve into the importance, advantages, and common types of metal surface treatment.

What is metal surface treatment? Metal surface treatment is the creation and application of a layer or physical barrier to protect the metal before coating occurs. This process includes metal cleaning, deburring, polishing, etc. It can not only increase the structural integrity of the metal, but also enhance these parts or components aesthetically.

But of course, there are some factors to consider when performing metal surface treatment, such as production speed, cost-effectiveness, and metal durability. You must ensure that everything is aligned with the company's goals and the application of metal parts. That is why it is recommended to carefully plan from metal stamping production to surface treatment.

In order for you to continue learning, the following are the steps for metal surface treatment:

Firstly, you need to clean the surface from the stamping compound and grinding oil. Then, apply organic or inorganic sealant. Rinse with deionized water. Finally, to remove moisture, you can place it in an oven or air dry it. Why is surface treatment necessary for metals? It is crucial to produce and design precision metal stamping parts. Therefore, it is necessary to plan surface treatment options. This process increases the service life of the metal, making it more important for use in other industries. In addition, it can expand your company as you know you are providing high-quality stamped parts.

In addition to the above statement, there are many reasons why we should perform surface treatment on metals, all of which are worth understanding:

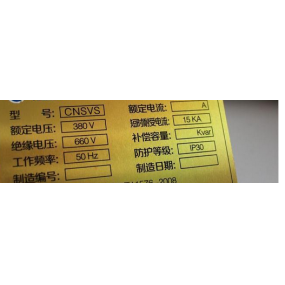

Corrosion inhibition - Non rusting metals are a good indication of reliable materials suitable for any application. Stamped parts must have high corrosion resistance to galvanic corrosion, pitting corrosion, and crevice corrosion. Improve appearance - Surface treatment makes the metal more pleasant and aesthetically balanced for decorative purposes. It can be matte or shiny, embossed or plain, etc. Improve durability - as mentioned earlier, it can extend the service life of metals. It can harden the surface of parts, which is highly needed in the production of stamped parts for medical equipment, building materials, and automotive parts. Enhanced electrical performance, color resistance, and chemical resistance - these benefits provide impeccable advantages in increasing the value of metals. Which industries use metal surface treatment? Almost everything we see, use, and build is the product of surface treatment of metal stamping parts for the entire equipment components. Companies such as industrial electronics, healthcare, industry, aerospace, communications, and others utilize this process to improve their tools, items, and equipment.

For example, in the electronics industry, we use it for covers, connectors, sensors, shelves, etc., which you can see in mobile phones, computers, and appliances. In the medical field, we perform surface treatment on stamped parts of laboratory equipment, such as equipment pumps, monitors, surgical equipment, etc.

This list is still ongoing, as our era today mainly relies on services and processes, as well as metal stamping, to produce customized high-quality metal parts.

Now that we have thoroughly studied the importance and advantages of metal surface treatment, it is time for you to consider selecting the appropriate method for the right materials and related finishes.

As is well known, different materials and products require additional surface treatments. We have many different types, but the following list will show you eight (8) common metal surface treatments for stamping parts that can typically produce high-quality results:

www.dggold.com

www.dggold.com

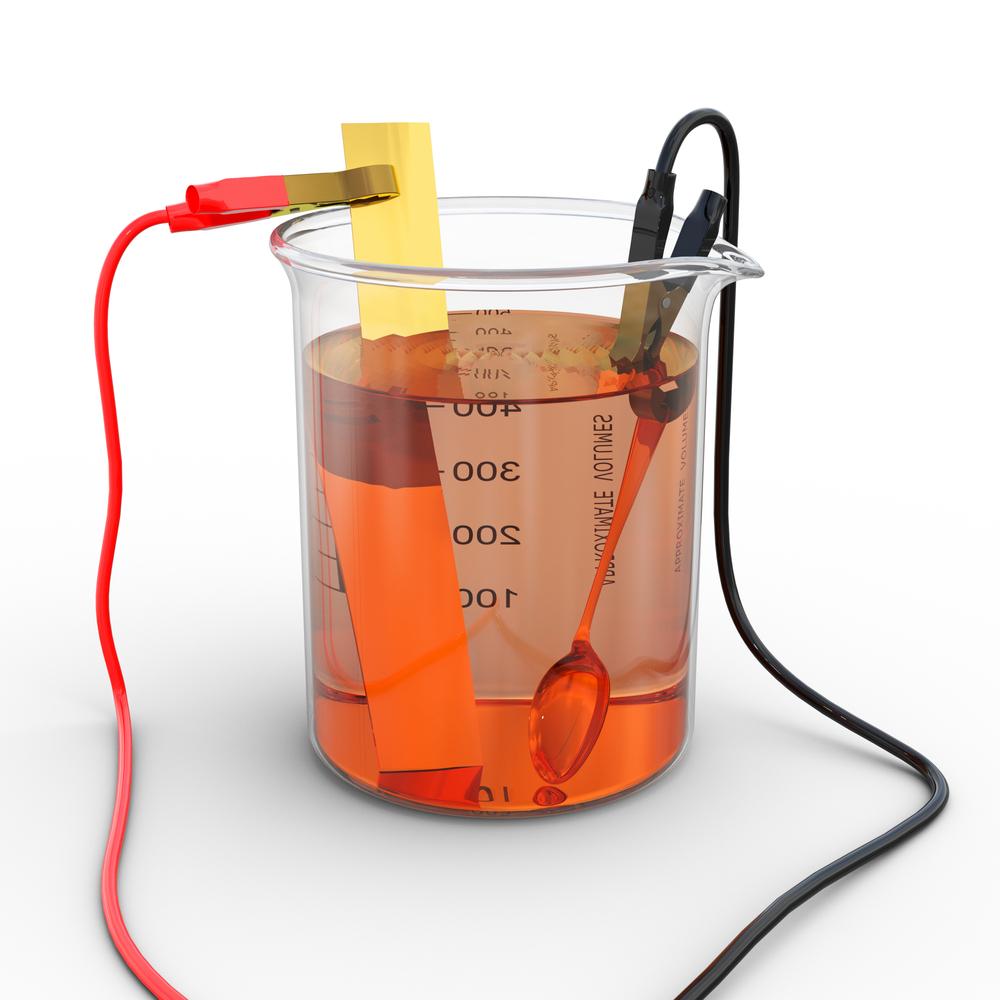

Electroplating is a chemical process that involves applying a thin metal coating on a major metal surface using an electric current. Due to its versatility - from miniature components to large products - this method is a widely used surface treatment approach. It aims to protect metals from corrosion, enhance surface value, and magnify their physical appearance.

This processing method is used for metal parts in laboratories, medical equipment, household appliances, and automobiles. In addition, electroplating is mainly suitable for various metals, such as:

Standard metals (such as copper, nickel, tin, zinc), precious metals (such as gold, silver, palladium, rhodium), and hard chromium and cadmium electroplating are the opposite of electroplating, as electroplating is not carried out by current. On the contrary, it uses chemical reactions to apply a metal coating on the target metal (or what we call the "substrate"). Its application is smoother and more uniform than electroplating. It is also more cost-effective throughout the entire process.

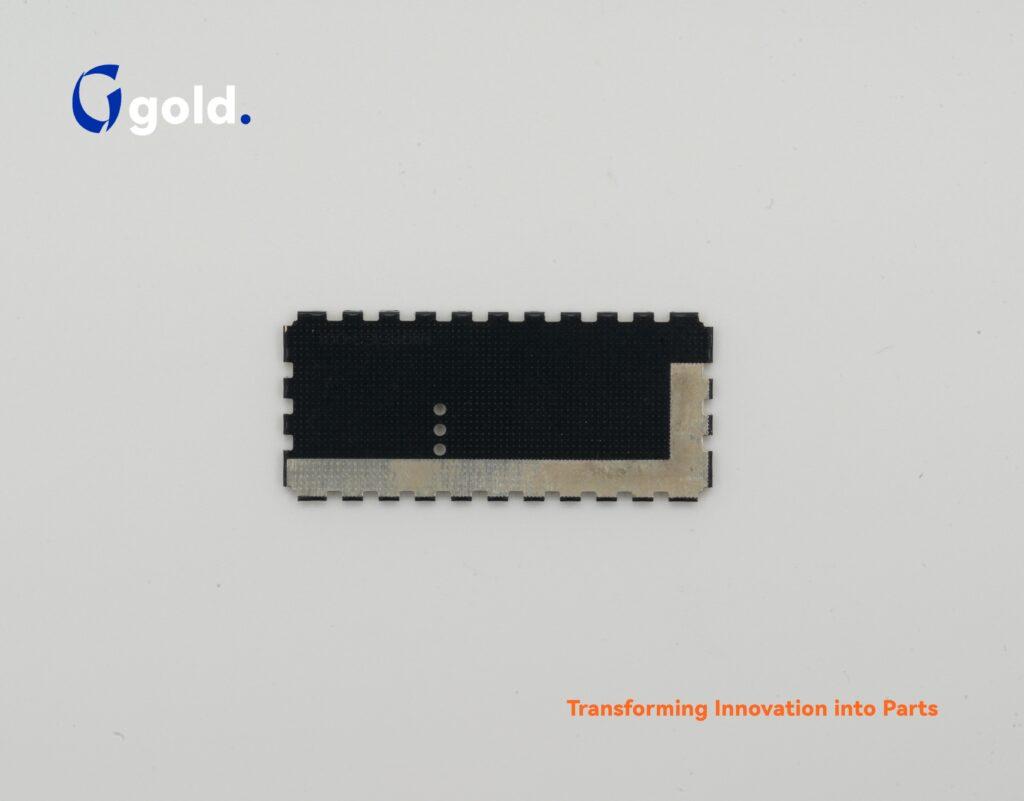

The metal used for this surface treatment is nickel. These products provide the majority of components for industries such as aerospace and gun manufacturers. Chemical plating is also beneficial for stamping metal parts, such as:

Aluminum steel copper zinc brass chemical coating, also known as powder coating, is a surface treatment where a smooth protective film is applied to the substrate by compressed air, resulting in the subsequent melting of the powder material. It makes stamped metal highly scratch resistant and crack resistant, corrosion-resistant, and valuable as a metal coloring agent.

Chemical coatings are widely used in automotive components, making them an ideal choice for customer preferences. In addition, the materials for this surface treatment are aluminum and steel.

Metal anodizing is the electrolytic oxidation of metal surfaces to form a protective film of oxide coating. It is highly suitable as a metal surface treatment to minimize wear and tear, resist corrosion, and make metal components more robust and complex.

On the other hand, it is not suitable for stamping parts with rough and damaged surfaces, as it can only be uniformly coated. It is limited to aluminum metal components only.

Hot dip galvanizing, also known as hot-dip coating, is a surface treatment. It is coated by immersing steel and iron stamping parts in a molten zinc bath. Through this treatment, metal components are most likely to have high corrosion resistance. The hot doping method is very popular in the manufacturing of consumer electronics and automotive metal parts industries.

Vacuum metallization is the process of applying protective metal barriers to smooth stamped parts. This surface treatment requires the metal to be placed in a can or container and sprayed with a metal coating there. It has a mirror finish suitable for decorative and design purposes, especially in the aerospace and automotive industries. Aluminum is the key metal for this method.

Painting and painting have many applications, such as spray painting, electrostatic painting, conductive painting, lubricant painting, and so on. This surface treatment provides excellent corrosion and rust resistance, and enhances the appearance of any metal stamping parts.

Thermal spraying, as a surface treatment, enhances the ability of metal components to eliminate or minimize scratches, peeling, and cracking on the metal surface by melting and heating the metal coating. It is used as a primer for large structural metal stamping parts.

www.dggold.com

www.dggold.com

Metal surface treatment has a significant impact on metal stamping. It can enhance and increase stamping parts in terms of durability, corrosion resistance, aesthetics, and other aspects. In terms of quality, it benefits all manufacturers, suppliers, and customers. No wonder this method requires careful planning.

But please note that everyone must be aware of the factors that need to be considered in the metal surface treatment of stamped parts. To prevent unnecessary outcomes, you should review some items, such as duration and tasks to be completed, goals of your company and partners, and requirements for the product.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque