Sheet metal cutting is an important process for forming sheet metal products. It includes traditional methods and process parameters such as cutting, punching, and bending forming, as well as various cold stamping die structures and process parameters, equipment working principles and operating methods, and new stamping technologies and processes.

For any sheet metal part, there is a certain processing process, also known as the process flow. With the differences in the structure of the sheet metal part, the process flow may vary, but overall it does not exceed the following points

1. Design and draw a part diagram of its sheet metal parts, also known as a three view diagram. Its function is to express the structure of its sheet metal parts in the form of drawings

2. Draw an unfolded diagram. That is, unfold a complex component into a flat piece

3. Cutting. There are many ways to cut materials, mainly including the following:

a. Cutting machine cutting. It is the process of using a cutting machine to cut out the dimensions of the unfolded shape, length, and width. If there are punching or corner cutting, it is then combined with a punching machine and a mold to form the shape

b. Punch cutting is the process of using a punch press to form a flat plate structure by unfolding parts on a sheet metal in one or more steps. Its advantages include short labor consumption, high efficiency, and reduced processing costs. It is often used in mass production

c. NC numerical control cutting When cutting materials in NC, the first step is to write a CNC Machining program. It is to use programming software to write the drawn unfolded diagram into a program that can be recognized by the NC CNC machining machine. Let it follow these programs step by step on an iron plate to punch out the structural shape of its flat plate

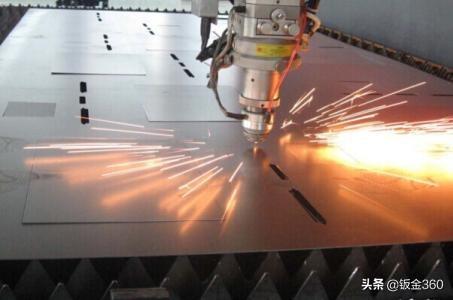

d. Laser cutting is the use of laser cutting to cut the structural shape of a flat plate on an iron plate

4. Flanging and tapping. Flanging, also known as hole drawing, is the process of drawing a slightly larger hole from a smaller base hole and then tapping it on the hole. This can increase its strength and avoid slipping. It is generally used for sheet metal processing with relatively thin plate thickness. When the plate thickness is large, such as 2.0, 2.5, etc., we can directly tap it without flanging

5. Punch processing. Generally, punch processing includes punching and corner cutting, punching and material dropping, punching and convex hull, punching and tearing, hole drawing, and other processing methods to achieve the processing purpose. The processing requires corresponding molds to complete the operation. For punching convex hull, there are convex hull molds, and for punching and tearing, there are tearing forming molds

6. Riveting. As far as our factory is concerned, commonly used riveting bolts, riveting nuts, riveting screws, etc. are usually riveted to sheet metal parts through punching machines or hydraulic riveting machines

7. Bending. Bending is the process of folding 2D flat parts into 3D parts. Its processing requires a folding machine and corresponding bending molds to complete the operation. It also has a certain bending sequence, and the principle is to fold the next one that does not interfere first, and fold the one that interferes later

8. Welding. Welding is the process of assembling multiple parts together to achieve the purpose of processing or welding the edges of individual parts to increase their strength. There are generally several processing methods, such as CO2 gas shielded welding, argon arc welding, spot welding, robot welding, etc. The selection of these welding methods depends on actual requirements and materials. Generally, CO2 gas shielded welding is used for welding iron plates; Argon arc welding is used for welding aluminum plates; Robot welding is mainly used when the workpiece is large and the weld seam is long. For example, for cabinet welding, robot welding can be used to save a lot of task time, improve work efficiency and welding quality

9. Surface treatment. Surface treatment generally includes phosphating film, electroplating multicolored zinc, chromate, baking paint, oxidation, etc. Phosphating film is generally used for cold-rolled plates and electrolytic plates, and its main function is to coat a protective film on the material surface to prevent oxidation; Furthermore, it can enhance the adhesion of its baking paint. Electroplating multicolored zinc is generally treated with cold-rolled sheet surface; Chromate and oxidation are generally used for surface treatment of aluminum plates and profiles; The specific surface treatment method is selected according to the customer's requirements

10. Assembly. Assembly refers to assembling multiple parts or components in a certain way to form a complete product. One thing to pay attention to is the protection of the components, which should not be scratched or damaged. Assembly is the final step of completing a component, and if the component cannot be used due to scratches or damage, it needs to be reworked, which will waste a lot of processing time and increase the cost of the component. Therefore, special attention should be paid to the protection of the component

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque