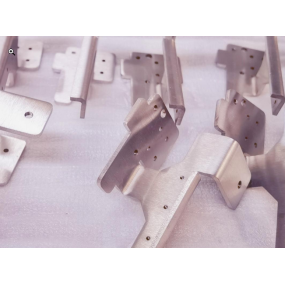

Sheet metal cabinet processing has always been a relatively complex processing technology, but due to differences in application industries and products, the processes used for sheet metal cabinet processing may also vary, but overall they are not significantly different. Do you know what are the common processes for processing sheet metal cabinets? Below, the editor of Aima Technology Co., Ltd. will introduce to you:

The common processes for processing sheet metal cabinets include the following:

1. Assembly process

During the processing of sheet metal cabinets, commonly used assembly methods include ground sample assembly, profile assembly, horizontal, vertical, and inverted assembly.

2. Cutting process

It is to cut the raw material according to the completed layout pattern, usually using methods such as manual cutting, mechanical cutting, punching processing, flame cutting, plasma gas cutting, and laser cutting. Sheet metal cabinet processing can be selected based on factors such as different technical requirements, batch size, and cost during cutting. Different cutting methods may result in different choices based on factors such as cutting and processing excess materials according to the drawing.

3. Bending process

Due to the complexity of bending, this may be a difficult step in sheet metal cabinet processing and metal manufacturing, and engineers must be very familiar with the bending properties of metals. Most bending machines have certain limitations on bending. Generally, the single-sided height is the size of the bending machine and the height of the upper blade. The solution can be to use multi sided large angle bending. The height of both sides should not exceed the maximum height of one side. In addition to all the limitations of the height of one side, it is also limited by the bottom edge: bending height<; the base.

4. Forming process

The forming process is the most critical design requirement in sheet metal cabinet processing, playing a crucial role in improving processing efficiency, product quality, and reducing costs. The forming process includes: manual forming, mechanical forming, top pressure forming, explosive forming, etc. Artificial shaping is a fundamental skill that traditional sheet metal workers must master; Mechanical forming is currently the most commonly used process, which achieves the formation of sheet metal workpieces through rolling and bending equipment, bending equipment and molds, rolling equipment and molds, bending equipment and molds.

Due to different forming methods, the cutting length of sheet metal cabinets varies according to the drawing. Therefore, everyone should consider carefully during the production and processing process. Otherwise, if the cutting size is too large, it will waste materials and increase costs, sometimes causing difficulties in processing; Insufficient cutting can result in defective workpieces. The process technology of processing and forming is the key to ensuring product quality and improving work efficiency.

In summary, we can see that the commonly used processes for sheet metal cabinet processing mainly include assembly, cutting, forming, and so on. However, in addition to these commonly used processes, there are also processes such as polishing, cutting, bending, spraying, surface treatment, etc. When choosing, you can choose the appropriate sheet metal cabinet processing technology according to your own needs in order to obtain high-quality sheet metal cabinet processed parts.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque