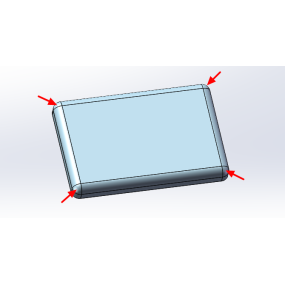

Aluminum alloy parts processing and hardware parts processing are generally carried out through CNC Machining and other methods. However, due to the low entry threshold of CNC machining, many small CNC machining workshops in the market have caused uncertainty in price and quality. Today, let's take a look at how to grasp the price of hardware parts processing, so that you can find CNC machining manufacturers with quality assurance and not unreasonably expensive hardware parts

Find a suitable CNC machining factory

Each manufacturer has its own advantages. Small factories are suitable for sample making, while large factories are suitable for large quantities. We need to find a suitable CNC machining factory based on our own needs, usually calculated by the length of product processing time, or by machine tools. For example, if your product can be made with a lathe, but you have to find a machining center to do it, it will definitely be much more expensive. The quotes in the industry are also very different, and they are very mixed. If you want to find a guaranteed one, it is best not to look for a store, but to look for a physical factory. As far as I know, factories that specialize in external processing are also very expensive. It is best to find factories that process for yourself but also for external processing. They are cheap in price and have high quality. Guaranteed.

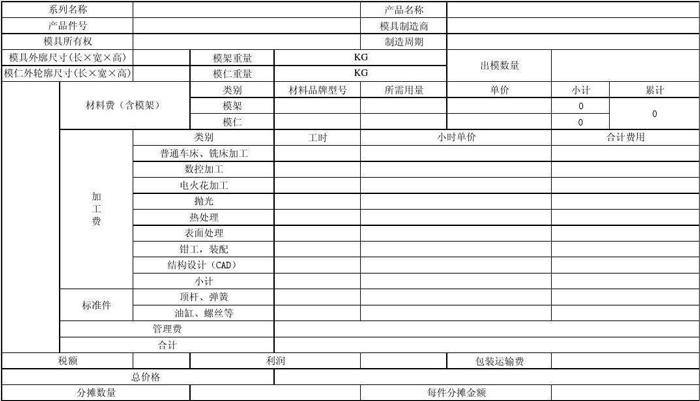

CNC machining quotation

How to calculate the processing price of hardware parts

1. First, we need to look at your drawings and technical requirements

2. There are differences in materials and labor in different regions, and some places even have significant price differences

3. Generally, parts are calculated based on material cost+processing cost+profit, and the processing cost depends on the process. The price of using different processing equipment is naturally different. Some are calculated based on working hours (turning time, grinding time, etc.), while others are calculated based on the process (such as how much does it cost to fold a folded plate, how much does it cost to drill a regular hole, etc.)

4. There is also an issue of quantity. If the quantity is large, it will be cheap. If it is a single piece, it will be miserable. Even if it is a small piece and the material is not retail, the price of your entire board will have to be calculated! For example, the 0.3 you mentioned is not commonly used by manufacturers. If you only have one or two pieces and only buy one board at a time (such as 1220 * 2440), then your material costs will be wasted.

5. If the parts processing factory can handle the problem on its own, then there is no problem. If the processing factory itself has some processes that need to be outsourced, the price will also increase accordingly. If you have already been outsourced, it is equivalent to going through two rounds of outsourcing! So when looking for a processing factory, you also need to find the right one, what they can do and what they are good at.

Specific CNC machining price calculation:

CNC lathe processing fee: The standard algorithm is hours * wages per hour+fixed expenses that should be shared, such as depreciation. The general processing fee for CNC machine tools is 60 yuan per hour. The machine tool is about 1 meter long and is a regular vertical lathe. The price has slightly increased by more than 10 yuan in areas with fewer machine tools. Of course, the price may vary depending on the processing capability of the machine.

Ordinary anodizing costs about 10-12 yuan per kilogram. The assembly depends on the specific product. It is usually calculated by quantity, how much does one unit cost.

Reference quotation for ordinary anodizing: 10 yuan per kilogram for black, 8 yuan per kilogram for white (silver), and 12 yuan per kilogram for color

The price is for reference only, and the current price of the company shall prevail.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque