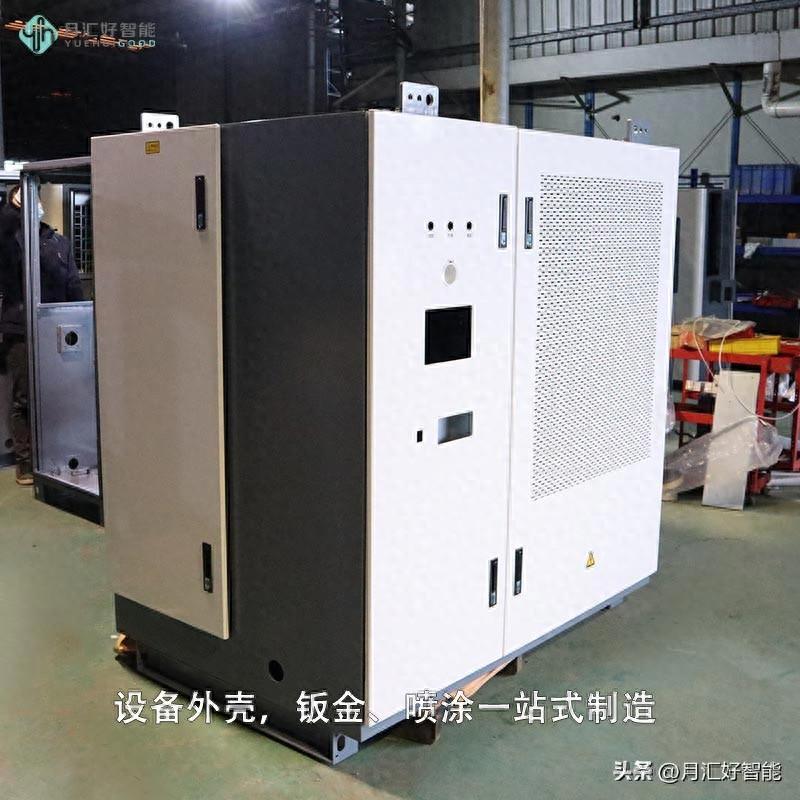

The Sheet Metal Processing technology for chassis and cabinets refers to the process of processing, forming, assembling, and surface treating metal sheets. In modern industrial production, sheet metal processing technology for chassis and cabinets has become a very important part, widely used in fields such as electronics, communication, healthcare, and transportation. When performing sheet metal processing on chassis cabinets, the following processes are usually used:

Chassis and cabinet sheet metal processing

1. Shear: Shear is the process of cutting metal sheets according to design requirements. Common cutting equipment includes shearing machines and CNC shearing machines, which can accurately cut metal sheets of different thicknesses and sizes.

2. Bending: Bending is the process of bending metal sheets into shape using a bending machine. By adjusting the mold and angle of the bending machine, different shapes and angles of bending processing can be achieved.

3. Stamping: Stamping is a process that uses a punch press to punch and process metal sheets into concave and convex shapes. Stamping technology can achieve complex shapes and structures, improving the accuracy and appearance of products.

4. Welding: Welding is the process of connecting metal plates through welding equipment. Common welding methods include spot welding, argon arc welding, laser welding, etc., which can achieve the connection of metal sheets of different materials and thicknesses.

5. Surface treatment: Surface treatment is the process of cleaning, spraying, sandblasting, electroplating, and other treatments on the surface of processed metal sheets. Surface treatment can improve the corrosion resistance and aesthetics of products.

Chassis Cabinet Sheet Metal Processing

Chassis Cabinet Sheet Metal Processing

The above are several common processes in the sheet metal processing of chassis and cabinets. Through the combination and application of these processes, diversified processing and production of metal sheets can be achieved to meet the needs of different industries and customers. With the development of technology and innovation in processes, the sheet metal processing technology for chassis and cabinets is constantly improving and enhancing, providing strong support for the development of the industry and the improvement of products.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque