Metal Stamping parts are widely used in various aspects of our lives, and their requirements are becoming increasingly high. Therefore, it is necessary to have some inspection standards for metal stamping parts to ensure the quality and stability of stamping products. Next, the editor from Yiwei will introduce the inspection standards for metal stamping parts.

1. Part Inspection Guide (Standard) Book

Simple metal stamping parts can be inspected by comparing various dimensions marked in the drawings, followed by the use of various measuring instruments such as tape measures, calipers, and stop and go gauges. Also, pay attention to some important tolerances marked on the drawing and ensure that the tolerance range is consistent with the drawing. For some high-precision products, strict tolerance requirements are required.

2. Sample of metal stamping parts

For some parts without gauges but with complex shapes that cannot be expressed in two-dimensional drawings. You can use a quadratic circle test. The signboard is a very intuitive reference, which can indicate whether the structure is qualified, surface treatment, and batch sharpness.

3. Excellent materials for metal stamping parts

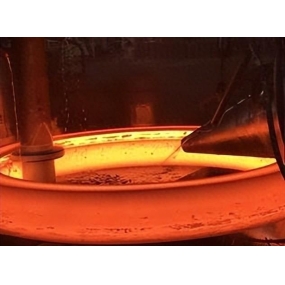

The adaptability of metal stamping materials to stamping forming processes becomes the stamping forming performance of sheet metal, including fracture resistance, mold adhesion, and formability.

1) Fracture resistance refers to the ability of stamping materials to resist rupture, generally measured by parameters such as forming limit;

2) Pastability refers to the ability of sheet metal to achieve consistency with the shape of the mold during stamping and forming;

3) Crystallization refers to the ability of a component to maintain its original shape within the mold after demolding. It is obvious that the greater the forming limit, the better the adhesion and formability of the material, and the better the stamping performance of the material.

4. Special inspection tool for metal stamping parts

The specialized inspection tools for metal stamping parts should be based on the actual situation of the parts and require proficient use.

The above are the inspection standards for metal stamping parts. For products with extremely high requirements, Yiwei Precision has specially developed automated visual inspection equipment for quality inspection. Automated visual inspection equipment can perform 100% inspection on products, and the internal high-resolution dedicated camera can inspect products from various dimensions to determine whether they meet the standards. This can achieve the goal of maximum detection efficiency while ensuring 100% reliability of component quality.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque