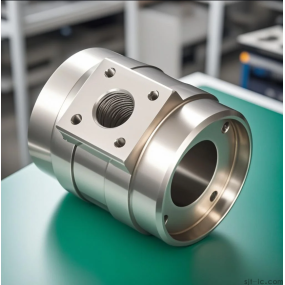

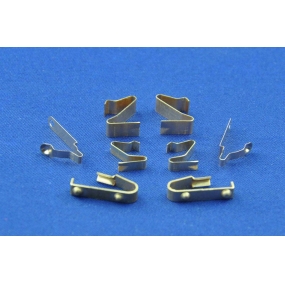

(1) Firstly, the stamping process of metal nameplates relies on the use of presses and molds to apply external forces to plates, strips, pipes, and profiles, causing them to undergo plastic deformation or separation, thereby obtaining the desired shape and size of the workpiece (stamped part) through forming processing

(2) Stamping and forging belong to plastic processing (also known as pressure processing), collectively referred to as forging. The raw materials for stamping are mainly hot-rolled and cold-rolled steel plates and strips. 60-70% of the world's steel is sheet metal, most of which are made into finished products through stamping

(3) The body, chassis, fuel tank, radiator fins of automobiles, steam drums of boilers, shells of containers, iron cores and silicon steel sheets of motors and electrical appliances are all stamped. There are also a large number of stamped parts in products such as instruments, household appliances, bicycles, office machinery, and household utensils.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque