A comprehensive cold processing technology for metal sheets, which includes cutting, punching, bending, riveting, mold forming processing methods, etc. Commonly used plates include hot-rolled plates, pickled plates, cold-rolled plates, galvanized plates, copper plates, aluminum plates, aluminum profiles, stainless steel, etc.

Processing method:

1. Sheet metal processing is carried out on sheet metal using equipment such as punching, folding, laser cutting machines, shearing machines, etc., which are mostly used for sample and small batch production and have high costs.

2. Sheet metal processing of sheet metal using fixed molds in equipment such as punching machines or presses is fast and cost-effective. However, the cost of molds is high, and they are often used for large-scale production during installation and replacement.

Sheet metal processing technology process:

1. Material cutting: Material cutting die, laser cutting, shearing machine, numerical punching.

2. Molding: Numerical punching, numerical folding, molding molds.

3. Other processing: riveting, tapping.

4. Welding: arc welding, resistance welding.

5. Surface treatment: powder coating, electrophoresis, electroplating, etc.

Shearing machine:

Used for cutting strip materials, it is mainly prepared for mold cutting and processing, or for cutting simple parts with regular shapes. Fast speed, low cost, low precision, can only process strip or block materials without holes or corners. Can be quickly changed.

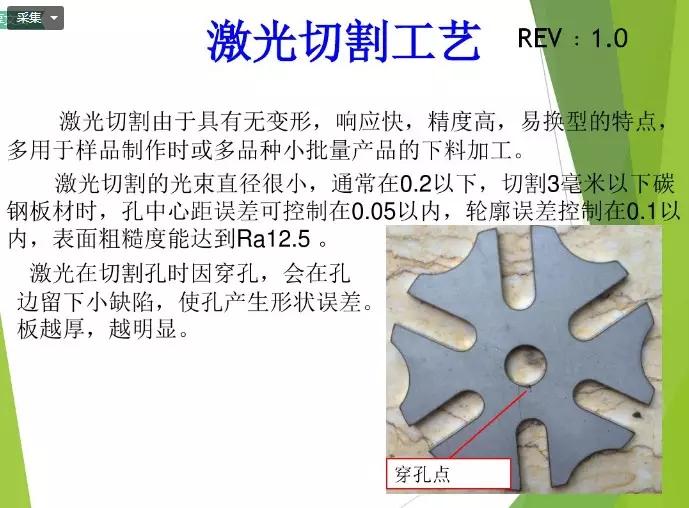

Laser cutting machine:

Using high-energy laser to irradiate the material being cut, causing the material to vaporize and produce voids, the beam moves to form a slit, and the structural shape of the part is cut out. A laser program needs to be written, which can cut various complex shaped parts. High cost and high precision. Can be quickly changed.

Number Rush:

Number Rush:

An automated punch press equipped with CNC control, which operates the punch press and processes parts through CNC programming instructions. By combining simple molds, multiple complex hollow and shallow stretching parts can be completed in one go. Large circular holes, square holes, waist holes, and various shapes of curved contours can also be processed through small mold step punching. Special processes such as louvers, countersunks, flanged holes, reinforcing ribs, embossing, etc. can also be carried out. Can be quickly changed.

CNC bending machine:

CNC bending machine:

The bending equipment for thin plates through molds is easy to operate and can process workpieces with side walls. Fast processing speed, high precision, and automatic compensation function. Can be quickly changed.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque