Precision stainless steel filter screen is a durable filtering metal product widely used in medical, automotive, environmental protection, food, chemical, chemical, mechanical and other fields. The processing method of precision stainless steel filter mesh in the manufacturing process can be somewhat difficult. Here, we will briefly describe how to choose the process for processing the filter mesh.

The early processing methods for precision stainless steel filter screens were laser drilling or stamping punching. Laser drilling has the advantage of low cost and is almost suitable for all metals. There is no requirement for the hardness of the metal, but scratches may occur on the edges during laser cutting, and there are some subtle burrs between the apertures. The influence of material thickness on tolerance requires a precision of 0.05%. Stamping punching requires the production of molds, and the cost of a single mold is relatively high. Metals with too high or too low hardness are prone to breakage, and the edges will also produce scratches similar to laser. This processing method is very slow in mass production and is only suitable for producing relatively small quantities of products.

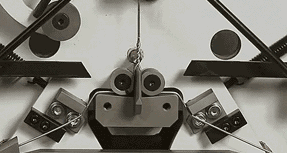

So besides the above two methods, are there any other processing methods? The answer is yes, which is to etch precision stainless steel filter screens. Etching can consider stainless steel materials with a thickness between 0.01-2mm, without the need to make molds, using metal film. The effect of this precision stainless steel filter screen is burr free, the product does not deform, the hole wall is vertical, and can ensure excellent accuracy. It can be mass-produced. When considering the processing of precision stainless steel filter screens, CAD drawings need to be made. The best design solution through etching processing is that the hole must be greater than 1.5 times the thickness, so that the design of etched precision stainless steel filter screens can meet its processing requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque