With the advancement and development of technology, more and more labor-intensive production enterprises are gradually realizing mechanized production, and more and more production processes are being replaced by CNC lathes for manual production and processing. So how should manufacturing enterprises choose CNC lathes? How to go to a CNC lathe manufacturer when choosing a CNC lathe? This issue is also a headache for many procurement personnel in production enterprises.

When purchasing CNC lathes and selecting CNC lathe manufacturers, the following points should be noted:

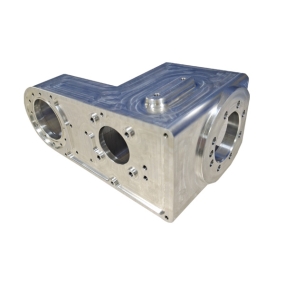

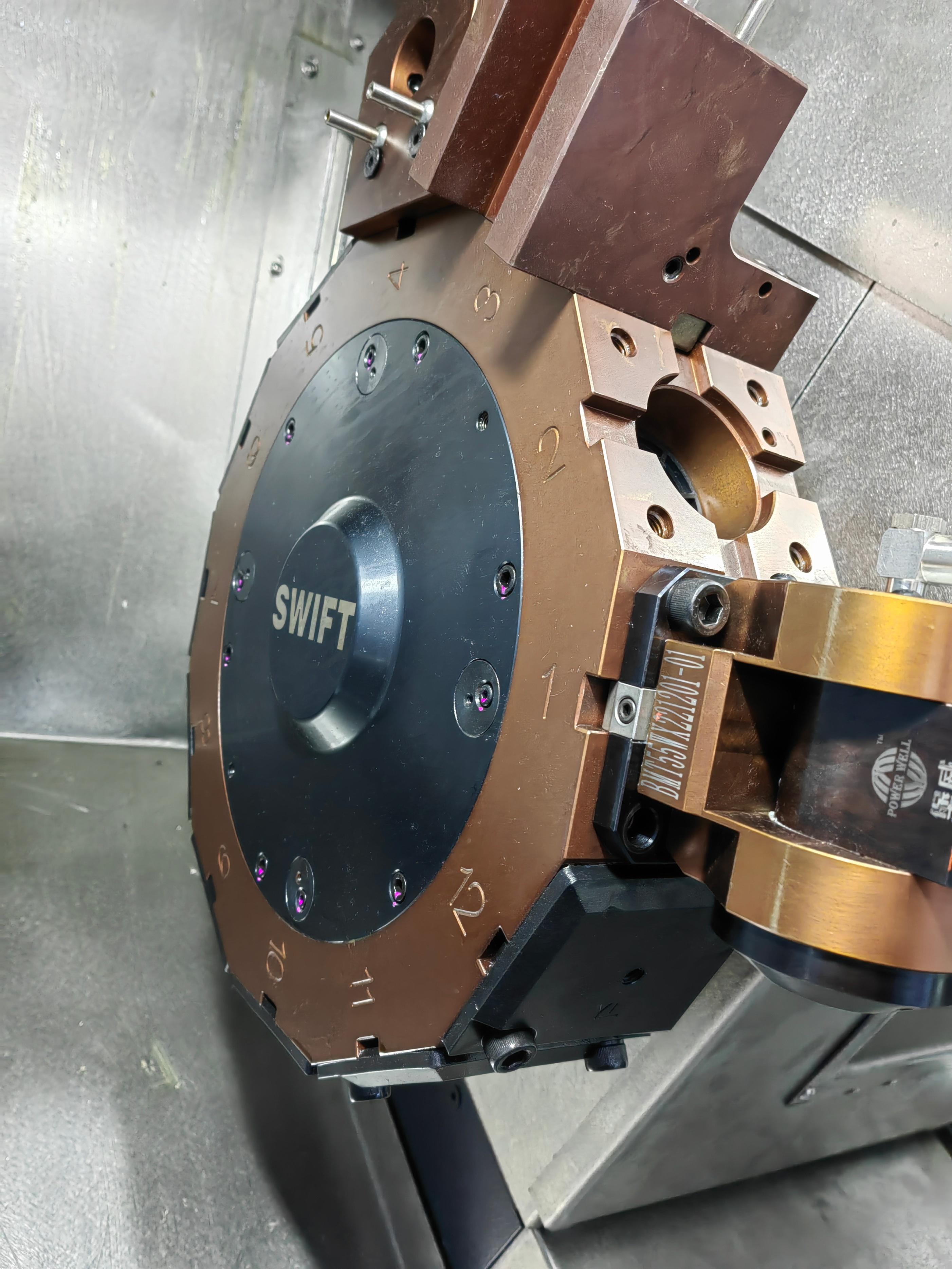

1. Selection of parameters for CNC lathes. Firstly, before purchasing a CNC lathe, it is necessary to determine some of the main parameters of the CNC lathe. There are relatively many main parameters of a CNC lathe, such as the turning diameter, machining diameter, machining length, number of tool holder positions, main motor power, CNC lathe system configuration, lathe positioning and repeat positioning accuracy, and so on. Users need to determine the specifications and models for purchasing a CNC lathe based on the length, diameter, and other parameters of the parts they are processing, and compare them with the main parameters of the CNC lathe. It should be noted that when determining the main parameters and specifications of the CNC lathe, it must be able to meet their own processing needs and leave a margin.

2. Selection of CNC lathe system. When choosing a CNC lathe system, several factors should be considered, such as accuracy, price, and ease of operation. In terms of accuracy, in recent years, the majority of CNC lathe manufacturers have used servo CNC systems with high precision. In terms of price, there may be differences in the prices of different brand systems and CNC lathe manufacturers' systems. Generally, imported systems are more expensive than domestic ones, and currently domestic ones are also good. In terms of operation, if you have previously used a certain brand of CNC system and the usage is still good, when purchasing a CNC lathe again, try to choose the same brand of CNC system, which can reduce time to learn other systems.

3. The appearance and noise of CNC lathes should also be taken into consideration. The fully protected CNC lathe has high appearance safety performance and good leak proof and anti-seepage performance for various types of oil and water. The lower the noise of a CNC lathe, the better. No matter which machine tool you choose, you must strictly follow the user manual to operate, use, and maintain it in order to extend the service life of the CNC lathe.

After discussing so many points to consider when choosing CNC lathe products, it is actually very important to choose a CNC lathe manufacturer. When choosing a manufacturer for purchasing CNC lathe products, the first thing to consider is the strength of the CNC lathe manufacturer and whether they have a very comprehensive after-sales service.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque