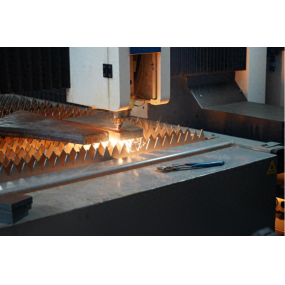

The manufacturing method of metal bellows: Bellows are thin and tortuous metal components that provide a sturdy and flexible pipe section that can be adjusted with changes in internal temperature and pressure conditions. Although they only have a slight appearance due to their reasonable structure, they still persisted thousands of times. Hydraulic forming:

1、 Hydraulic forming is such a method. Internal high-pressure forming begins with creating a mold in the desired corrugated tube shape. Once set, the mold enters a room and the engineer can seal it.

2、 They put a piece of metal into a sealed chamber, sealed each end, and filled the remaining space with water. When water enters, the pressure rises, pushing the metal plate closer to the mold until it reflects this shape. This method is usually effective in producing irregular shapes and is also effective in the production of corrugated pipes.

3、 It is also very simple to perform this process over and over again using the same mold.

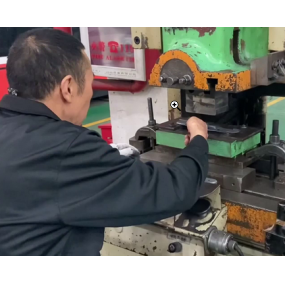

The manufacturing method of metal corrugated pipes: Another manufacturing method for metal corrugated pipes is stamping forming. This alternative method involves using an enlarged mandrel forming machine to create a spiral from inside the cylindrical metal tube. From a different perspective, roll forming uses a machine to roll each coil to a predetermined diameter from the outside. This is a common method when you need small custom designs.

Cold forming is a room temperature process, during which the quality of the corrugated tube changes and becomes increasingly difficult. It occurs in several stages and involves no cutting or welding. On the contrary, the machine presses the bellows into various molds until they reach a complete stage.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque