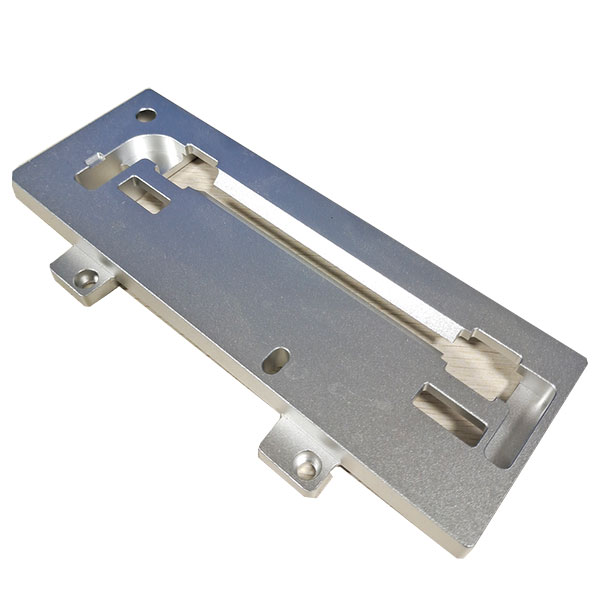

Reducing the risk of damage during CNC Machining of aluminum alloys is key to ensuring product quality and production efficiency. Here are some specific measures and suggestions: 1 Reasonable selection of cutting parameters and cutting speed: For CNC machining of aluminum alloys, the appropriate cutting speed should be selected based on the material properties and processing requirements of the aluminum alloy. Excessive cutting speed may lead to tool wear and accumulation of cutting by-products, while excessively low cutting speed can result in low machining efficiency. Feed rate: Choose a reasonable feed rate based on the complexity of the workpiece and processing requirements. Excessive feed rate may lead to excessive cutting force, resulting in workpiece deformation and decreased machining quality; A low feed rate can lead to low processing efficiency.  2. Use appropriate tool types and materials: Choose tools suitable for CNC machining of aluminum alloys, such as high-speed steel or hard alloy tools. These cutting tools have high hardness and wear resistance, which can effectively reduce the risk of damage during the machining process. Geometric parameters of cutting tools: Ensure that the geometric parameters of the tool (such as edge angle, edge radius, etc.) are suitable for machining requirements, in order to reduce vibration and cutting force, and lower the risk of damage. 3. Proper tool cooling and lubrication of cutting fluid: During the CNC machining of aluminum alloy, an appropriate amount of cutting fluid should be used for cooling and lubrication. Cutting fluid can lower cutting temperature, reduce cutting force and workpiece deformation, while also reducing tool wear and damage. Cooling control: Reasonably control the flow rate and temperature of cutting fluid to ensure uniform distribution and continuous supply of cutting fluid. Excessive flow rate may lead to material waste, while insufficient flow rate can result in poor cooling effect. 4. Ensure the stability of clamping and fixing fixture selection: Use appropriate fixtures and fixture forces to ensure the stability and rigidity of the workpiece during aluminum alloy CNC machining. This helps prevent displacement or vibration of the workpiece during the machining process, thereby reducing the risk of damage. Clamping method: Choose the appropriate clamping method based on the shape of the workpiece and processing requirements. Ensure even distribution of clamping force to avoid excessive local stress that may cause deformation or damage to the workpiece. 5. Real time monitoring of machining process: During the CNC machining process of aluminum alloy, closely monitor the changes in machining parameters and the working status of the machine tool. Timely detect and handle abnormal situations, such as excessive cutting force, intensified vibration, etc., to avoid damage. Periodic inspection: Regularly conduct processing quality inspection, including workpiece size measurement, surface quality inspection, and material performance testing. This helps to promptly identify potential quality issues and take measures for improvement. 6. Improve design and process optimization of structural design: In the product design phase, avoid unreasonable structures such as sharp corners and significant wall thickness variations to reduce stress concentration and deformation risks during aluminum alloy CNC processing. Optimize the process flow: Based on the CNC processing requirements and material characteristics of aluminum alloy, optimize the process flow and processing sequence. Reasonably arrange the connection between processing steps and procedures to reduce the risk of damage during the processing.

2. Use appropriate tool types and materials: Choose tools suitable for CNC machining of aluminum alloys, such as high-speed steel or hard alloy tools. These cutting tools have high hardness and wear resistance, which can effectively reduce the risk of damage during the machining process. Geometric parameters of cutting tools: Ensure that the geometric parameters of the tool (such as edge angle, edge radius, etc.) are suitable for machining requirements, in order to reduce vibration and cutting force, and lower the risk of damage. 3. Proper tool cooling and lubrication of cutting fluid: During the CNC machining of aluminum alloy, an appropriate amount of cutting fluid should be used for cooling and lubrication. Cutting fluid can lower cutting temperature, reduce cutting force and workpiece deformation, while also reducing tool wear and damage. Cooling control: Reasonably control the flow rate and temperature of cutting fluid to ensure uniform distribution and continuous supply of cutting fluid. Excessive flow rate may lead to material waste, while insufficient flow rate can result in poor cooling effect. 4. Ensure the stability of clamping and fixing fixture selection: Use appropriate fixtures and fixture forces to ensure the stability and rigidity of the workpiece during aluminum alloy CNC machining. This helps prevent displacement or vibration of the workpiece during the machining process, thereby reducing the risk of damage. Clamping method: Choose the appropriate clamping method based on the shape of the workpiece and processing requirements. Ensure even distribution of clamping force to avoid excessive local stress that may cause deformation or damage to the workpiece. 5. Real time monitoring of machining process: During the CNC machining process of aluminum alloy, closely monitor the changes in machining parameters and the working status of the machine tool. Timely detect and handle abnormal situations, such as excessive cutting force, intensified vibration, etc., to avoid damage. Periodic inspection: Regularly conduct processing quality inspection, including workpiece size measurement, surface quality inspection, and material performance testing. This helps to promptly identify potential quality issues and take measures for improvement. 6. Improve design and process optimization of structural design: In the product design phase, avoid unreasonable structures such as sharp corners and significant wall thickness variations to reduce stress concentration and deformation risks during aluminum alloy CNC processing. Optimize the process flow: Based on the CNC processing requirements and material characteristics of aluminum alloy, optimize the process flow and processing sequence. Reasonably arrange the connection between processing steps and procedures to reduce the risk of damage during the processing.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque