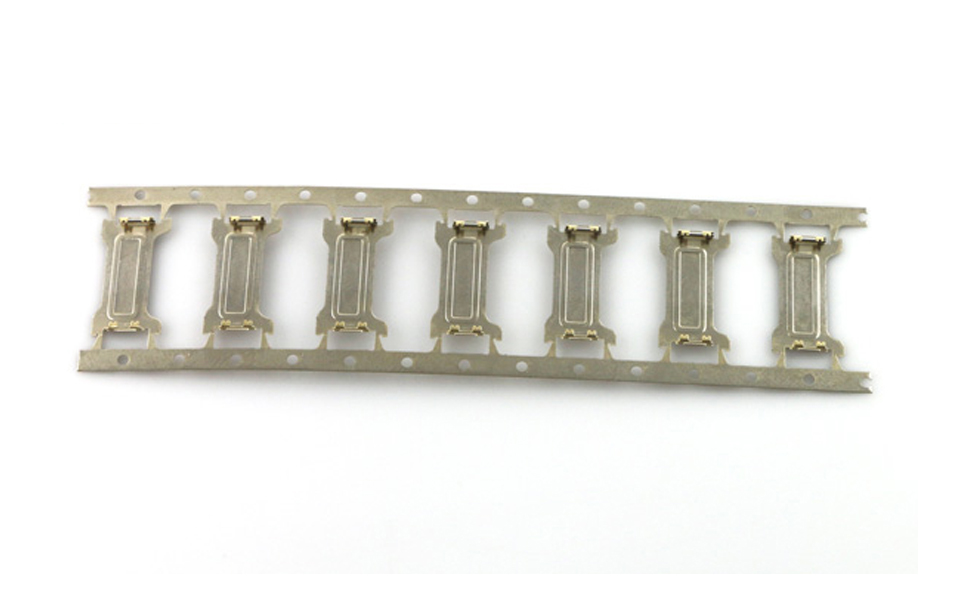

In Metal Stamping processing, correcting bending and center bending are two important processes. They can ensure product quality and improve production efficiency. So, how can we improve the quality of bending?

Firstly, we need to understand the potential issues that may arise during the bending process. For example, scratches on the surface of materials, inaccurate bending angles, etc. To address these issues, we can take the following measures:

1. Use high-quality raw materials. High quality raw materials can ensure the performance and appearance of products.

2. Strictly control the temperature and pressure during the bending process. This helps prevent material deformation and damage.

3. Regularly inspect the equipment to ensure its normal operation. Equipment failure may lead to a decrease in product quality.

4. Train operators to enhance their skills and experience. Skilled operators can better control the bending process and improve product quality.

Through the above measures, we can effectively improve the bending quality in metal stamping processing. This can not only enhance the competitiveness of the product, but also bring more profits to the company. Therefore, we should attach great importance to the bending process, continuously optimize the production process, and provide customers with higher quality products.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque