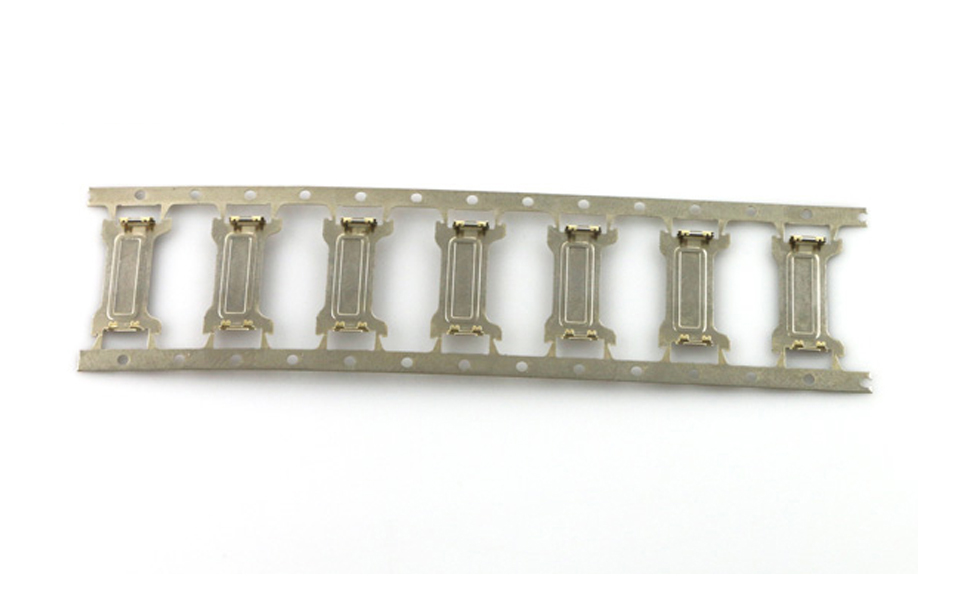

In Metal Stamping processing, the issue of burrs is a problem that cannot be ignored. Burrs not only affect the appearance quality of the product, but may also have an impact on its performance. Therefore, it is particularly important to check and deal with burrs in metal stamping processing.

Firstly, we need to understand what burrs are. Burrs refer to small protrusions that occur during metal cutting due to irregularities on the surface of the tool or workpiece. These protrusions can form sharp edges on the surface of the product, which can easily scratch human skin and even cause serious personal injury.

So, how to check for burrs in metal stamping processing? There are several common methods that can help us with the inspection.

1. Visual inspection method, which involves observing with the naked eye whether there are obvious burrs on the surface of the product.

2. Touch method, which involves gently touching the surface of a product with your fingers to feel if there are sharp edges.

3. Magnifying glass inspection method, which uses a magnifying glass to carefully observe the details of the product surface.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque